Logic control method for electric grounding switch

A logic control and ground knife technology, applied in the electrical field, can solve problems such as unreliable action, danger, and other equipment or on-site staff hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

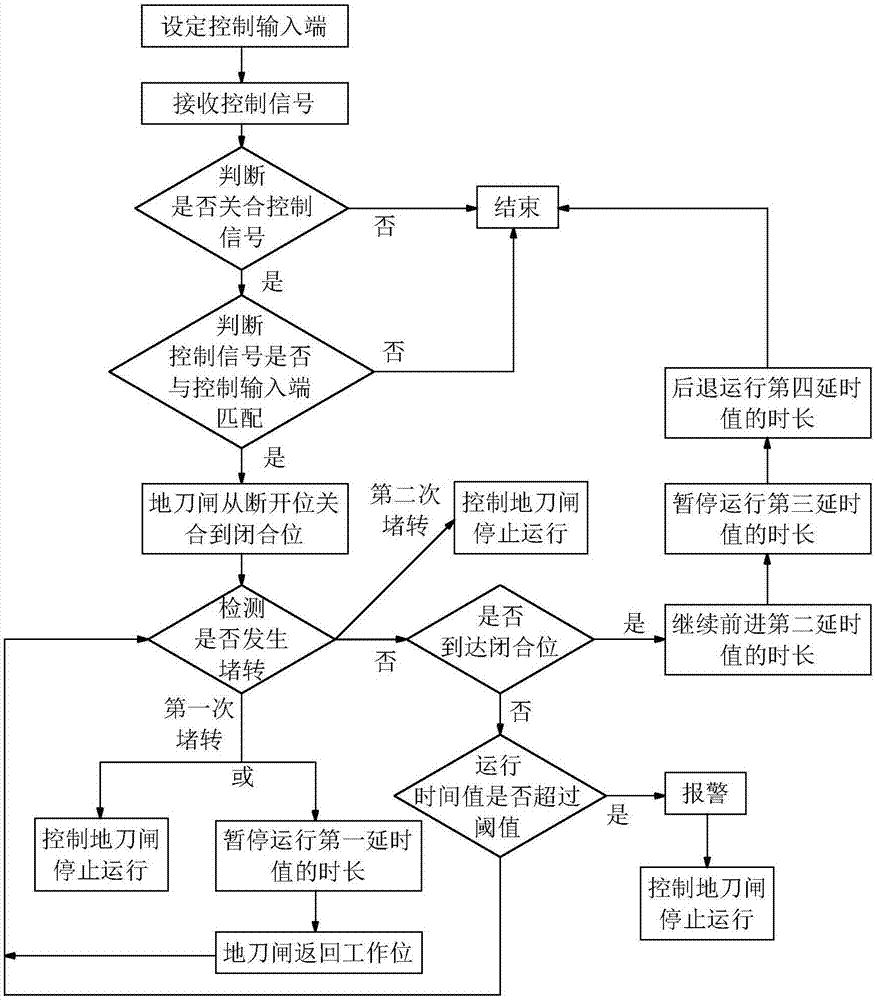

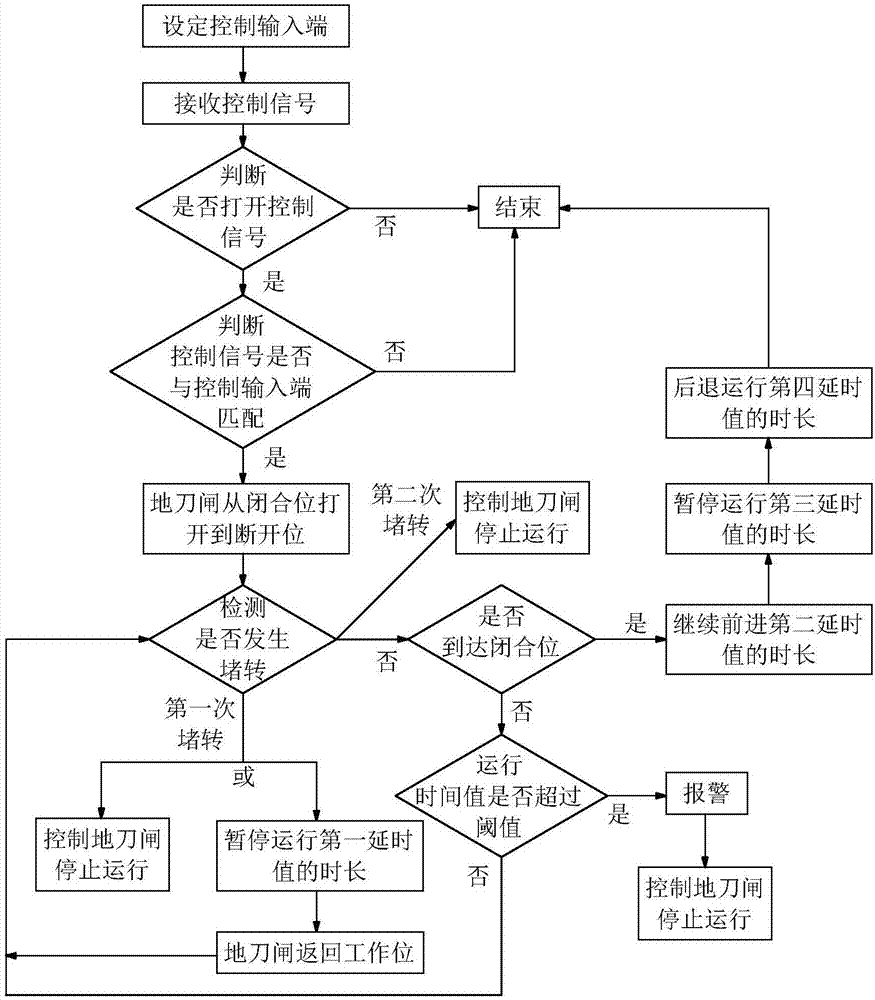

[0022] Such as figure 1 , figure 2 As shown, the logic control method of the electric ground knife of the present invention, the electric ground knife includes a ground knife switch, a main control module, at least two control input terminals and a motor drive mechanism, and the main control module is electrically connected to the control input terminal and the motor drive mechanism respectively. Connection, the motor drive mechanism is connected with the ground knife switch to drive the ground knife switch to move, here there can be multiple control input terminals, set at the local position or a remote position, the main control module includes MCU or CPU and its auxiliary circuits, and the motor drives The drive shaft of the mechanism is connected with one end of the ground knife switch, and the ground knife switch is driven to rotate through the drive shaft of the motor, so that the ground knife switch moves in two positions of a closed position and an open position.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com