A method for measuring the texture of cold-rolled steel plate

A technology of cold-rolled steel plate and measurement method, which is applied in the direction of measurement device, preparation of test samples, instruments, etc., and can solve problems such as inability to measure texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In order to solve the above-mentioned technical problems, the present invention provides a method for measuring the texture of cold-rolled steel plates, including:

[0032] Step S1: Treat the surface of the cold-rolled steel plate to obtain the sample 1 to be tested;

[0033] Step S2: Carry out electron backscatter diffraction technology detection to the test sample 1, measure the ∥ND texture ratio within the range of the maximum orientation deviation of 20°, and obtain the result A;

[0034] Step S3: Carry out argon ion etching on the test sample 1 to obtain the test sample 2;

[0035] Step S4: detect the argon ion etching depth T on the surface of the test sample 2;

[0036] Step S5: Carry out electron backscatter diffraction technology detection to the test sample 2, measure the ∥ND texture ratio within the range of the maximum orientation deviation of 20°, and obtain the result B;

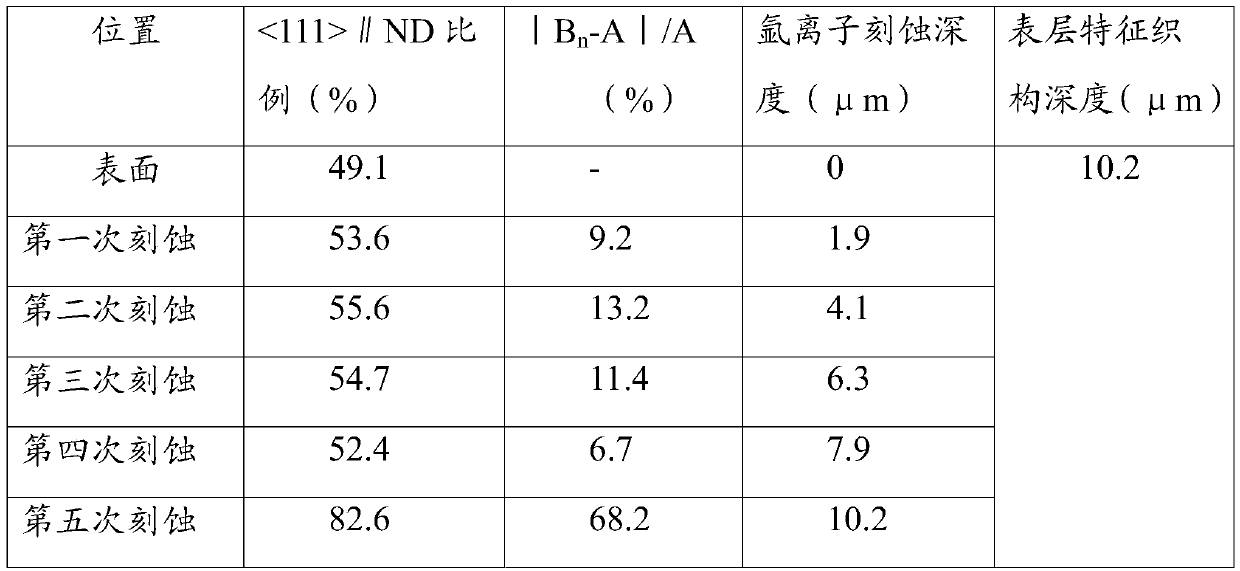

[0037] Step S6: Repeat Step S3-Step S5 until |B N When -A| / A≥50%, the final argon...

Embodiment 2

[0047] In this embodiment, the present invention is described in detail by taking DC04 continuous annealing steel plate as an example.

[0048] Step B1: First select the cold-rolled steel plate, and use the method of electrolytic polishing to treat the surface. The electrolyte used is a mixture of perchloric acid: alcohol: glycerol at a ratio of 7:2:1. After polishing, the surface of the sample is smooth The degree can meet the EBSD detection requirements, and the EBSD test sample 1 is obtained.

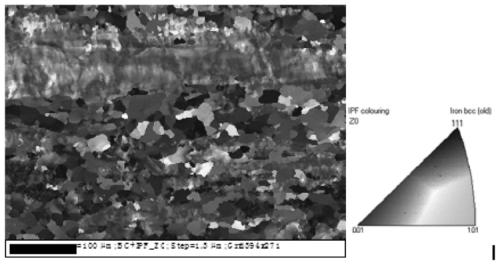

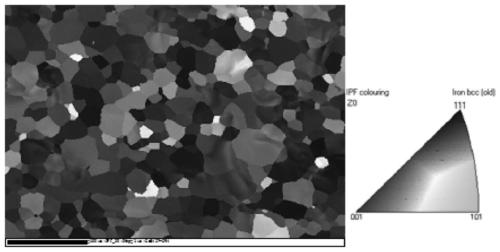

[0049] Step B2: Use a field emission scanning electron microscope and an EBSD probe to conduct Texturecomponent analysis on the EBSD sample 1 to be tested, and measure the ratio of the ∥ND silk texture. The maximum orientation deviation range is 20°, and the result A is obtained. The grain orientation imaging image of the surface texture of the test sample 1 detected by EBSD is as follows figure 1 shown.

[0050] Step B3: using a depth profiling ion gun to perform argon ion etching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com