Hydraulic control system for overcoming harmful oscillation of oil cylinder of four-roll crusher

A hydraulic control system, roll crusher technology, applied in fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of shortening the service life of crushing rollers, affecting product quality, running coarse materials, etc. To achieve the effect of avoiding frequent adjustments and violent shocks, avoiding inaccurate settings, and improving protection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

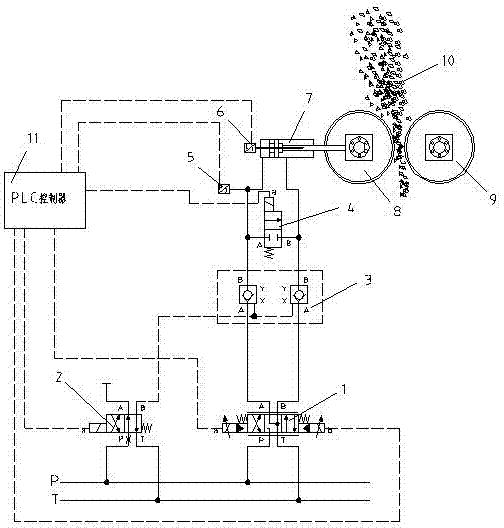

[0015] Example 1: see figure 1 , a hydraulic control system to overcome the harmful vibration of a four-roller crusher oil cylinder, the hydraulic control system includes a proportional reversing valve 1, a two-position four-way electromagnetic reversing valve 2, a hydraulic lock 3, and a two-position two-way electromagnetic on-off valve 4. Pressure sensor 5, displacement sensor 6, hydraulic cylinder 7, moving roller 8, fixed roller 9 and PLC controller 11, the P port of the proportional reversing valve 1 is connected to the oil inlet pipe P, and the T port of the proportional reversing valve 1 The port is connected with the oil return pipe T, the A port and the B port of the proportional reversing valve 1 are respectively connected with the two A ports of the hydraulic lock 3, and the two B ports of the hydraulic lock 3 are respectively connected with the rodless rods of the hydraulic cylinder 7. The control port X of the hydraulic lock 3 is connected to the B port of the two...

Embodiment 2

[0016] Example 2: see figure 1 , a hydraulic control method for overcoming harmful vibration of a four-roller crusher oil cylinder, the method is as follows:

[0017] 1) Start the hydraulic system through the PLC controller 11. The PLC controller 11 detects and feedbacks the position of the oil cylinder 7 through the displacement sensor 6, and the feedback result is passed through the proportional reversing valve 1 to realize the advance of the oil cylinder to the working position of the preset value. After holding, the crushing roll gap is formed between the moving roll 8 and the fixed roll 9, and its position is automatically adjusted by PID, and the adjustment process takes a certain time, and then maintains a basic stability;

[0018] 2) Start the upper belt discharging, the material 10 passes through the crushing roll gap maintained between the relatively rolling moving roller 8 and the fixed roller 9 and is crushed and passes through. During the use process, when the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com