Combination wall for demountable and mountable combination house

A combined house, dismantling technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of steel-frame cement board houses and iron-clad houses, poor living environment, inconvenient transportation, use and recycling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

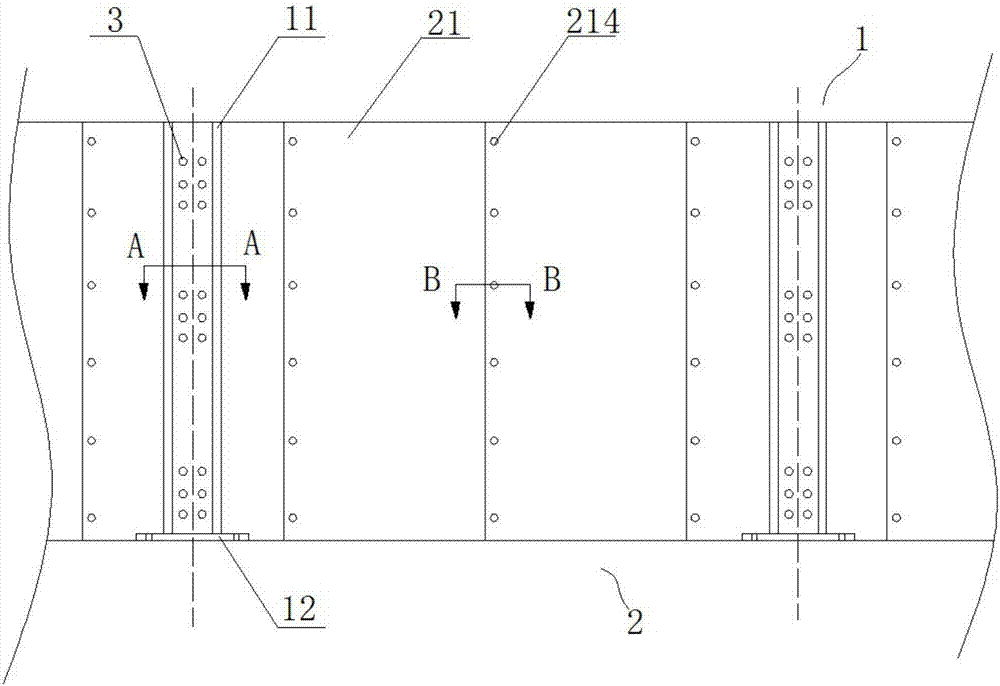

[0031] refer to Figure 1 to Figure 6 , in this embodiment, there is provided a detachable combined wall for a combined house, the combined wall includes at least two combined columns 1 arranged at intervals in the transverse direction, and spliced wall panels combined with the combined columns 1 2.

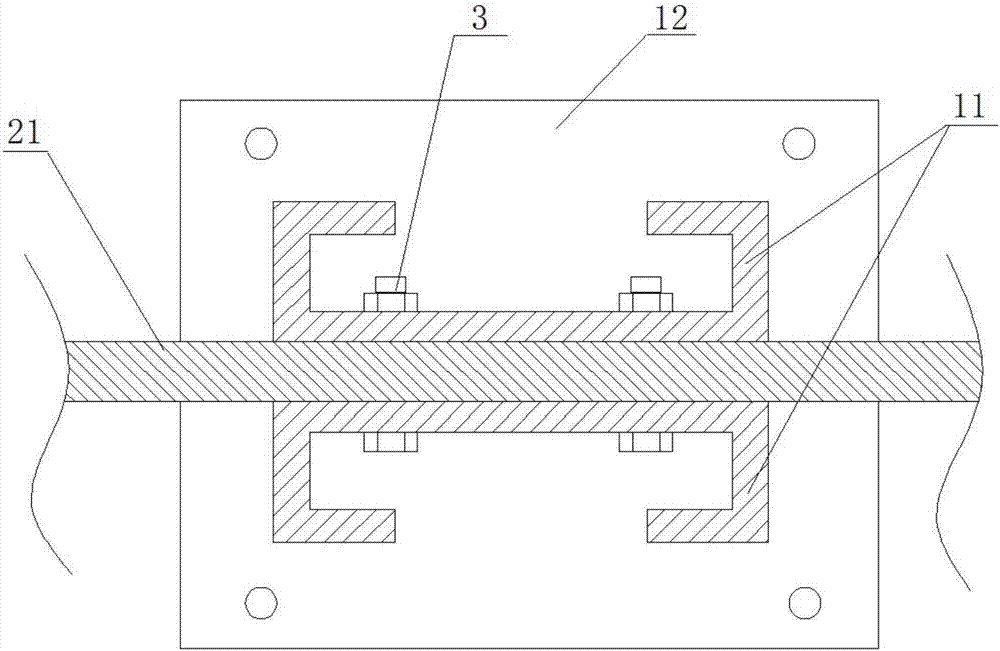

[0032] Specifically, each combined column 1 includes two C-shaped cold-formed thin-walled steel 11 extending along the height direction of the wall, and the openings of the two C-shaped cold-formed thin-walled steels 11 are arranged opposite to each other ( figure 2 It is clearly shown in the figure), preferably, the wall thickness of the C-shaped cold-formed thin-walled steel 11 is in the range of 2-3 mm.

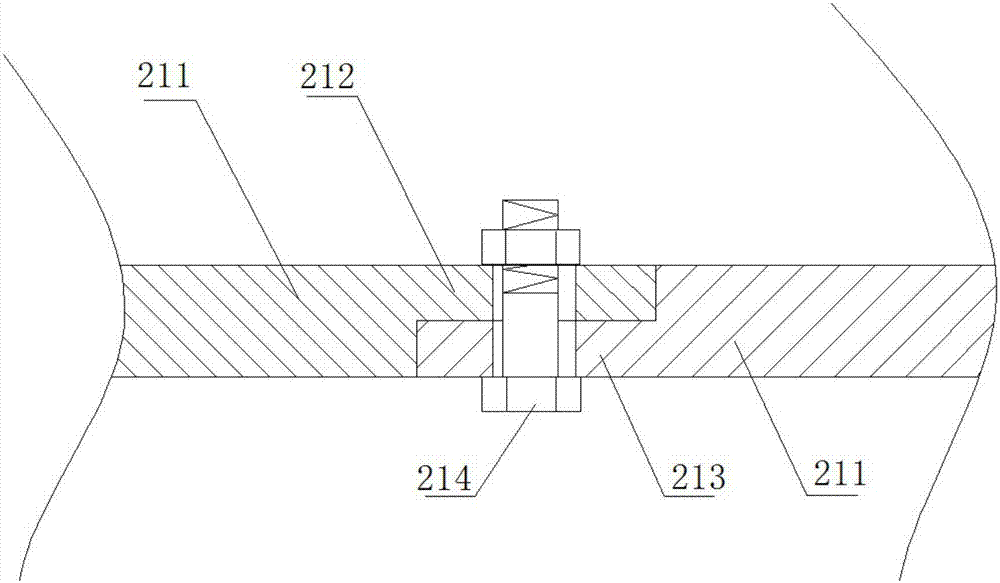

[0033] Specifically, the spliced wall panel 2 includes a plurality of spliced panels 21 that are spliced side by side. combined reference image 3 with Figure 4, each splicing plate 21 extends along the height direction of the wall, and has the same length as ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com