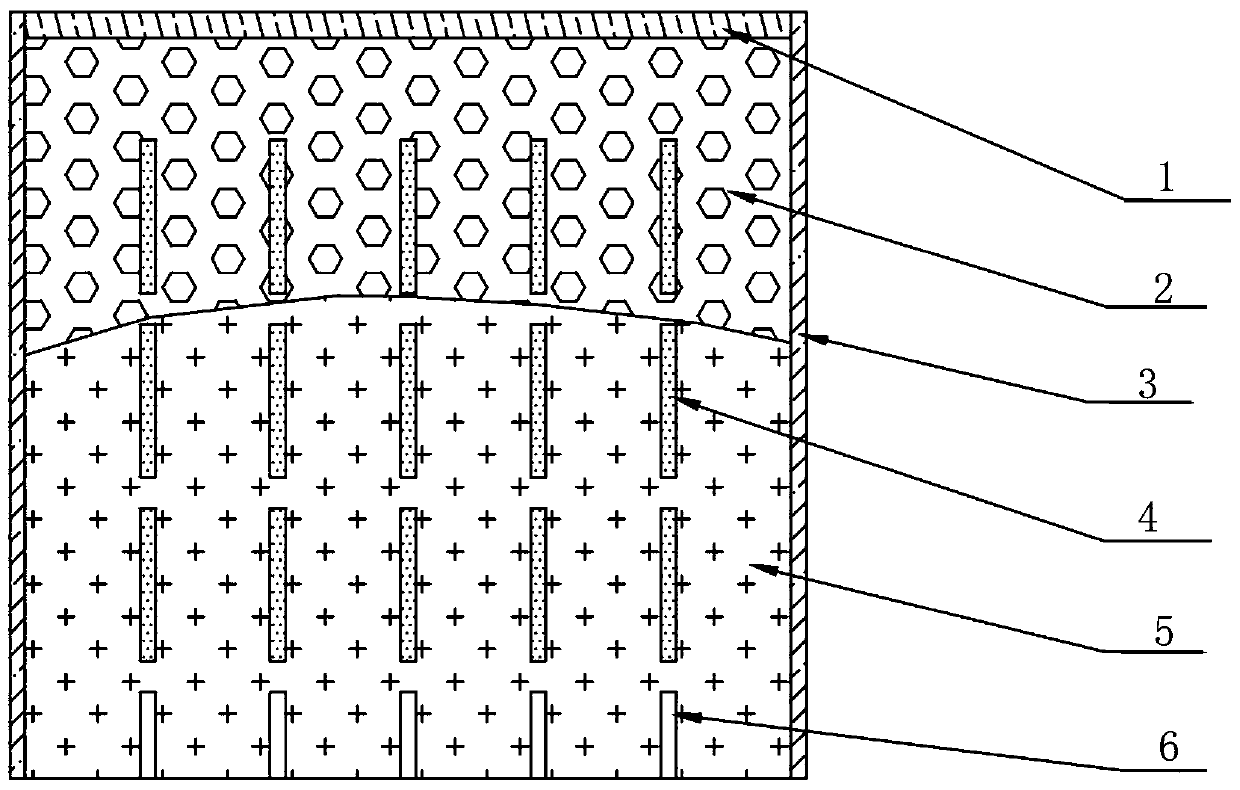

A composite anode for aluminum electrolytic cell

A composite anode and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolysis, can solve the problems of large fluctuations in electrolyte composition, affecting the stable operation and efficiency of electrolytic cells, and increasing the volatilization loss of liquid electrolyte, so as to increase the way of adding raw materials and promote stable and efficient operation , Expand the effect of raw material addition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Fillers are added to the composite anode aluminum frame, the raw materials in the fillers account for 58% of the total weight of the fillers, the electrolysis temperature is 760-850°C, and the aluminum content of the product is greater than 99.92%. The raw material is alumina. The filler is added by adding the kneaded filler into the aluminum frame. Install shelling and discharging exhaust mechanism around the composite anode.

Embodiment 2

[0046] Fillers are added to the composite anode aluminum frame, the raw materials in the fillers account for 25% of the total weight of the fillers, the electrolysis temperature is 810-890°C, and the aluminum content of the product is greater than 99.00%. The raw materials are alumina and magnesia. The filling method is to add the kneaded filling into the aluminum frame after cooling. Install shelling and discharging exhaust mechanism around the composite anode.

Embodiment 3

[0048] Fillers are added to the composite anode aluminum frame, the raw materials in the fillers account for 91% of the total weight of the fillers, the electrolysis temperature is 680-760°C, and the aluminum content of the product is greater than 99.50%. The raw materials are alumina and magnesia. The filling method is to shape the kneaded filling into irregular small pieces and then add it to the aluminum frame. A shell-breaking exhaust mechanism is installed around the composite anode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com