Multifunctional groove box cutting machine and using method thereof

A cutting machine and multi-functional technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of increased labor intensity, inability to slot, and few fulcrums, so as to improve the quality of urban environment, improve the efficiency of slotting, Effect of improving groove quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

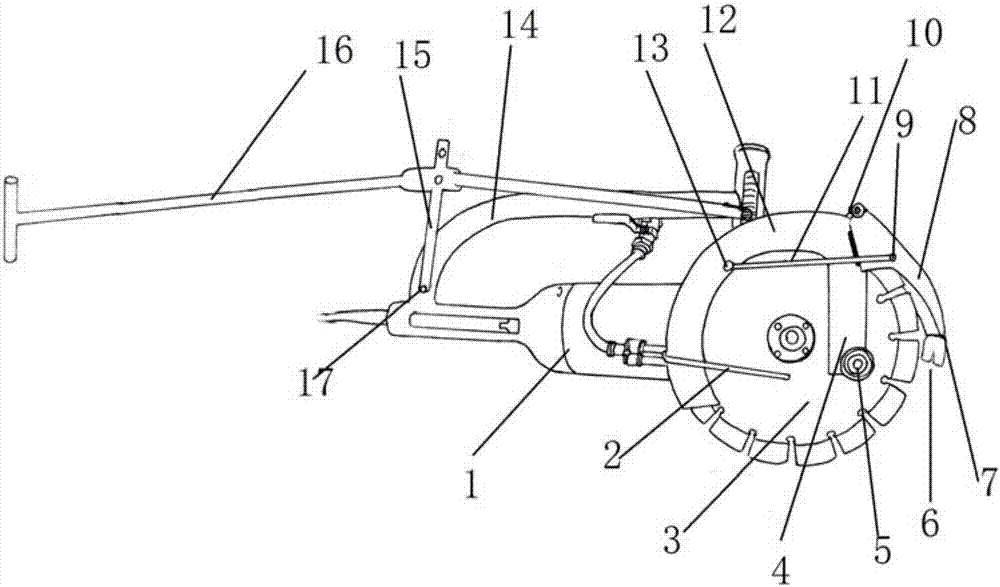

[0031] A multi-functional slot box cutting machine, the cutting machine includes a body 1, a motor is installed in the body 1, the motor is connected with a cutting saw blade 3 through a transmission mechanism, the motor drives the cutting saw blade 3 to rotate through the transmission mechanism, and the body 1 is equipped with There is a protective cover 12 for wrapping the cutting saw blade 3, and the protective cover 12 is provided with a guide assembly for feeding the cutting machine; The roller 5 that is used for rolling is arranged; The start-up of motor among the present invention, motor drives cutting saw blade 3 to rotate by transmission mechanism, and cutting saw blade 3 cuts the wall surface or the ground that needs cutting, is provided with protective cover 12 in the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com