Hydraulic manipulator

A manipulator and hydraulic technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of bad electric-driven manipulators, high protection requirements, and high cost of construction, and achieve the effect of improving labor productivity, low protection level, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

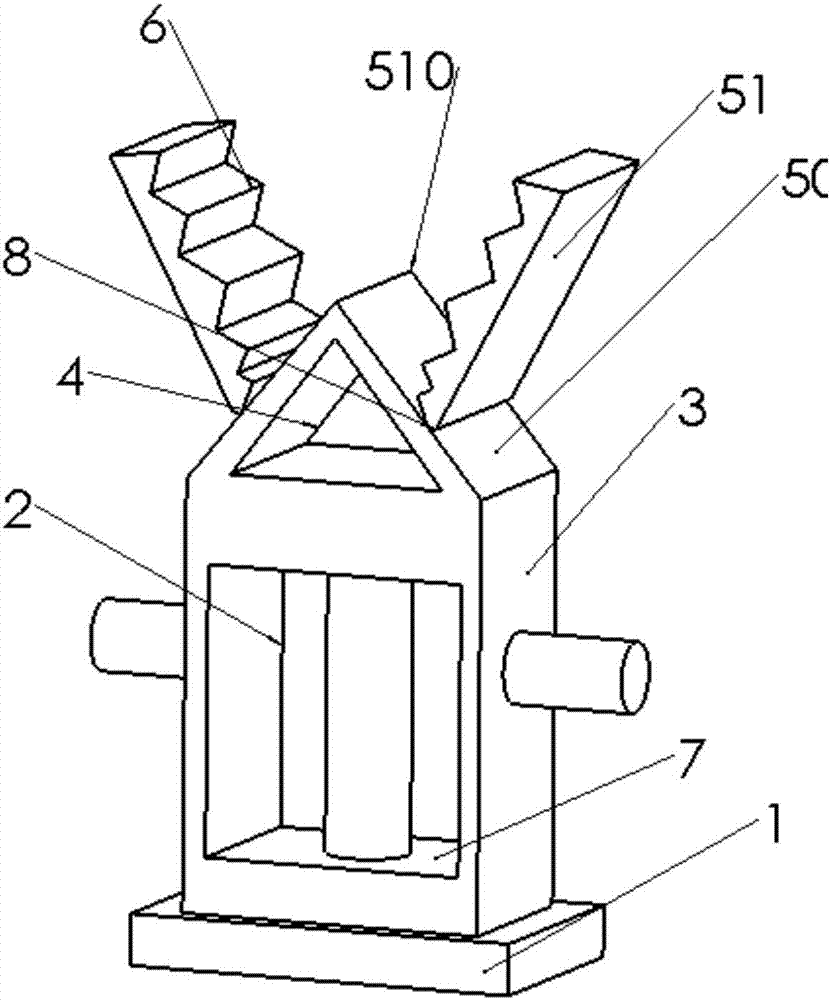

[0012] A hydraulic manipulator, the rotary hydraulic manipulator of the large-scale hydraulic manipulator includes a frame 1, a rotary cylinder 2, a manipulator cylinder outer cavity 3, a piston rod 4, and a manipulator device 5; the left end of the shell of the rotary cylinder 2 is screwed The frame 1 is fixed, the rotating shaft 7 of the rotary oil cylinder 2 is integrated with the outer chamber 3 of the manipulator oil cylinder, and the right end of the outer chamber 3 of the manipulator oil cylinder is fixedly connected with the manipulator device 5. 51, and the two are rollingly connected; hydraulic oil enters the rotary cylinder 2 to push the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com