Electric stirrer

An electric stirrer and stirring shaft technology, which can be applied in the directions of mixer accessories, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve problems such as falling into

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

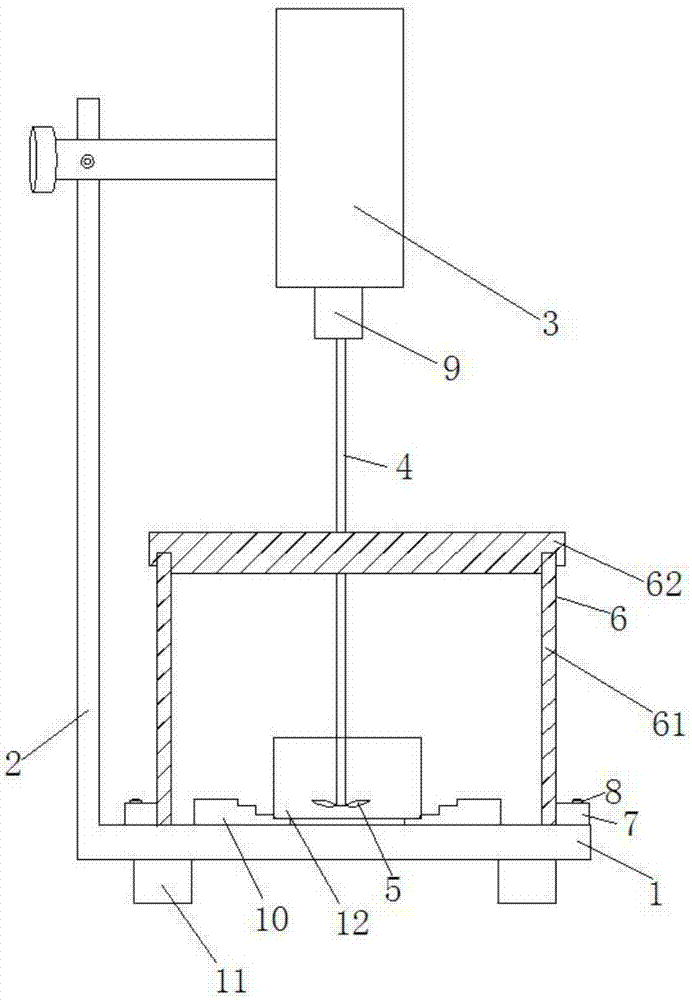

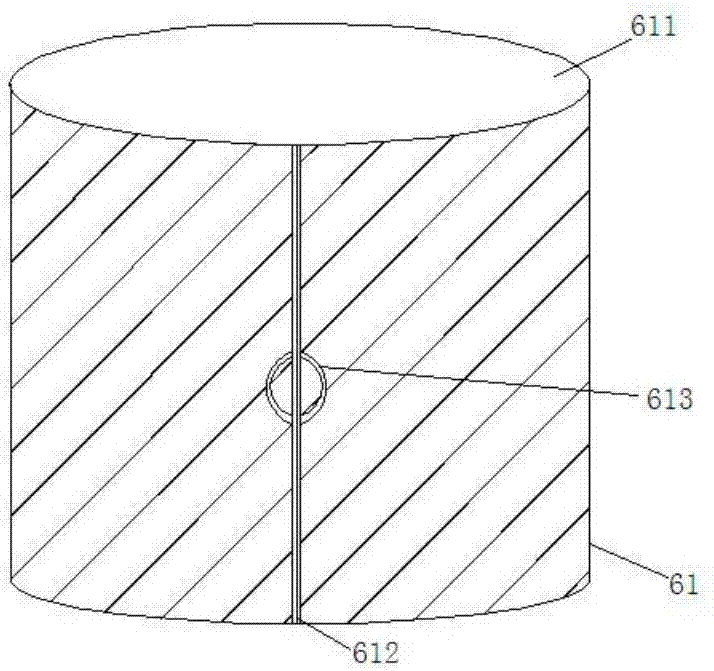

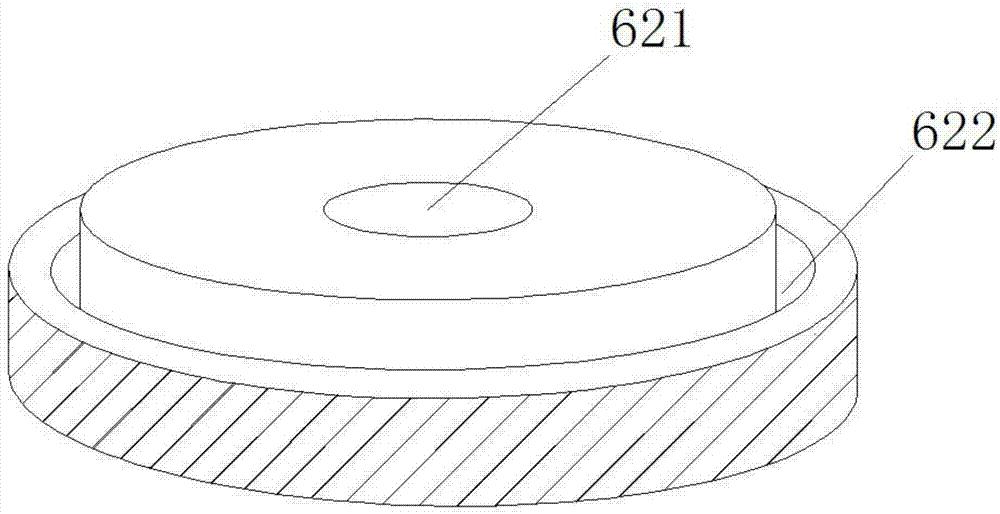

[0026] Such as figure 1 , figure 2 , image 3 As shown, an electric mixer includes a base 1, a support 2 is provided on the base 1, a motor 3 is provided on the top of the support 2, and the motor 3 is detachably connected with the stirring shaft 4, and the stirring shaft 4 Connected with the stirring paddle 5, the electric agitator also includes a protective cover 6, the protective cover 6 includes a protective cover body 61 and a protective cover 62, the protective cover body 61 is placed on the base 1, and the protective cover The upper part of the body 61 is provided with an opening 611, and the protective cover 62 is provided with a through hole 621 that allows the stirring shaft to pass through. The through hole 621 is in clearance fit with the stirring shaft 4, and the bottom of the protective cover 62 is provided with an annular groove. 622 , the annular groove 622 cooperates with the opening 611 .

[0027] The electric stirring shaft of the present invention is pr...

Embodiment 2

[0029] Based on Example 1, such as figure 1 As shown, the protective cover body 61 is provided with a protrusion 7, and the protrusion 7 is provided with a bolt 8, and the base 1 is provided with a bolt hole matched with the bolt. The protective cover body 61 is provided with a bolt 8, and the base 1 is provided with a bolt hole, so that the protective cover body 61 and the base 1 are connected by bolts, so that the protective cover body 61 is conveniently dismounted from the base 1, and the protective cover body 61 can be conveniently protected. Cleaning of the cover body 61, while in use, the protective cover body 61 can be fixed on the base 1 to prevent stirring and vibration or the experimenter from accidentally touching the protective cover 6 to cause the protective cover 6 to shift and affect the stirring.

Embodiment 3

[0031] Based on Example 1, such as figure 2 As shown, the protective cover body 1 is provided with a sliding door 612 , and the sliding door 612 is provided with a handle 613 . A sliding door 612 is provided on the protective cover body 61 , and a handle 613 is provided on the sliding door 612 to facilitate experimenters to put the container 12 containing the reactant into the protective cover 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com