Center pivot sprinkling machine

A sprinkler and circular technology, which is applied in the field of circular sprinklers, can solve problems such as poor passability, poor farmland ground, blocking, etc., and achieve the effect of simple and reasonable structure and improved ground passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

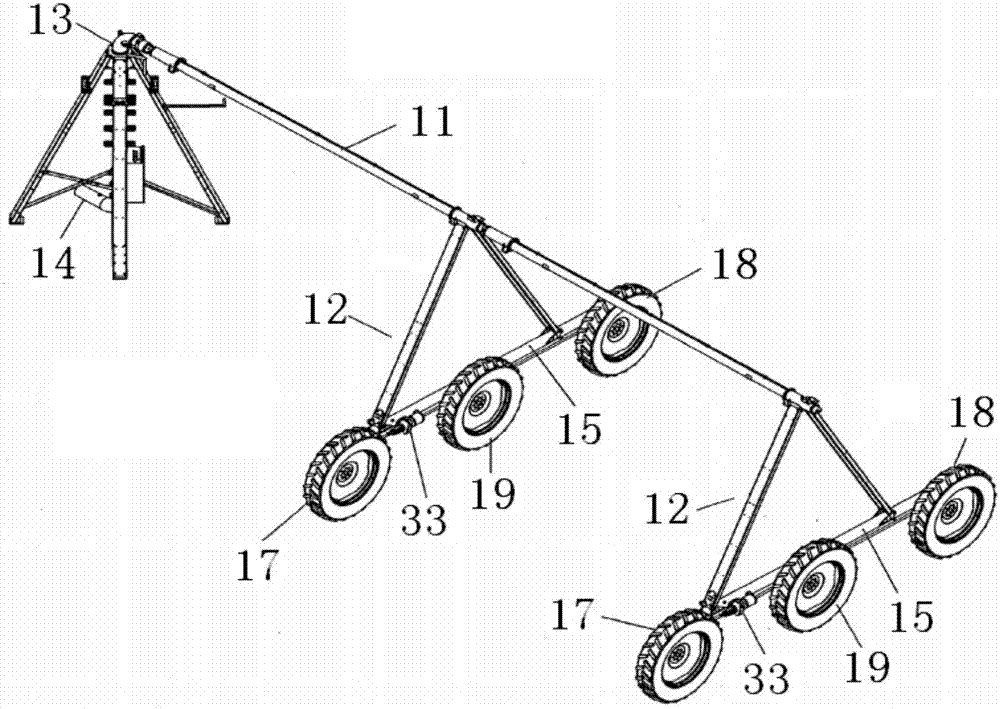

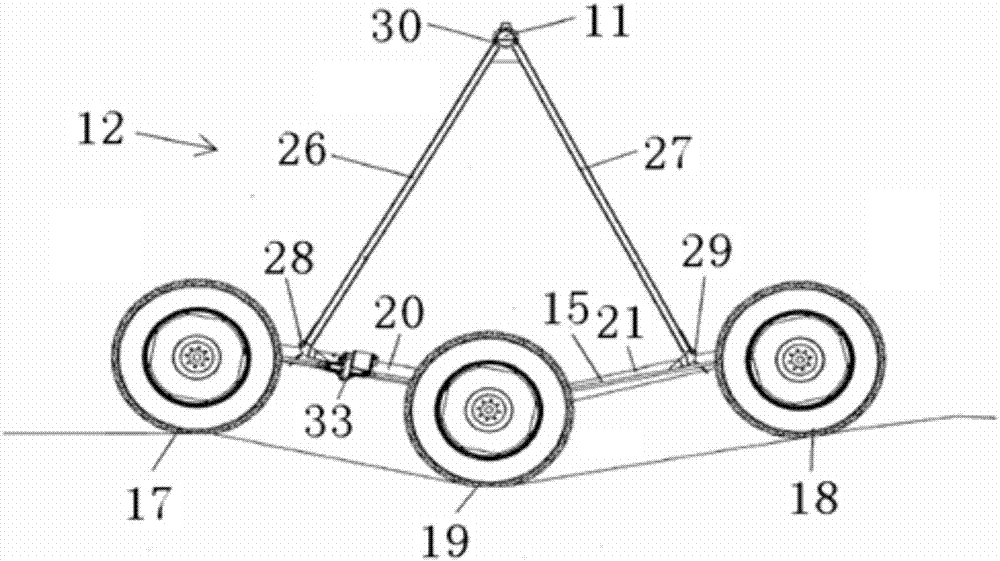

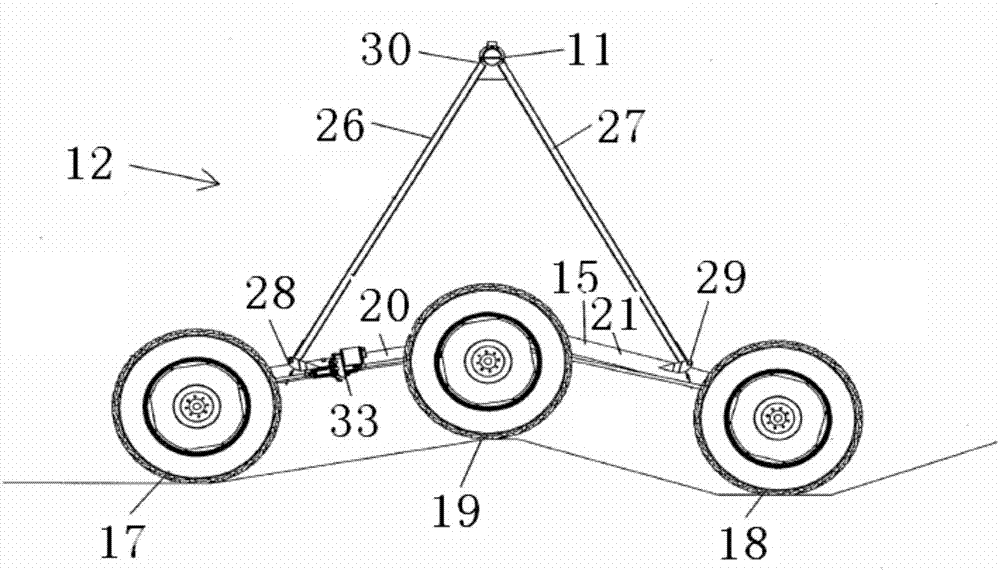

[0016] Such as Figure 1 to Figure 3 As shown, the circular sprinkler of the present invention includes a fixed central pivot 13, a water supply pipe 14, a pipeline 11 and a drive tower 12, the water supply pipe 14 is arranged below the fixed central pivot 13, and the pipeline One end of 11 is rotatably connected on the top of the fixed central pivot 13, and the pipeline 11 communicates with the water supply pipe 14; the pipe wall of the pipeline 11 is provided with a plurality of nozzles; the drive tower 12 The top supports the pipeline 11, and the drive tower 12 includes a first bracket 26, a second bracket 27, a beam 15, a first wheel 17, a second wheel 18, a third wheel 19 and a drive motor 33, and the first Support 26, second support 27 and crossbeam 15 are connected to form a triangular structure, and described crossbeam 15 comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com