Press plate and outgoing line matching structure for transformer and outgoing line method of press plate and outgoing line matching structure

A matching structure and transformer technology, applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of complex structure of transformer pressure plate and outgoing line, difficult to ensure installation size, etc., and achieve simple structure Ingenious, reduced labor costs, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

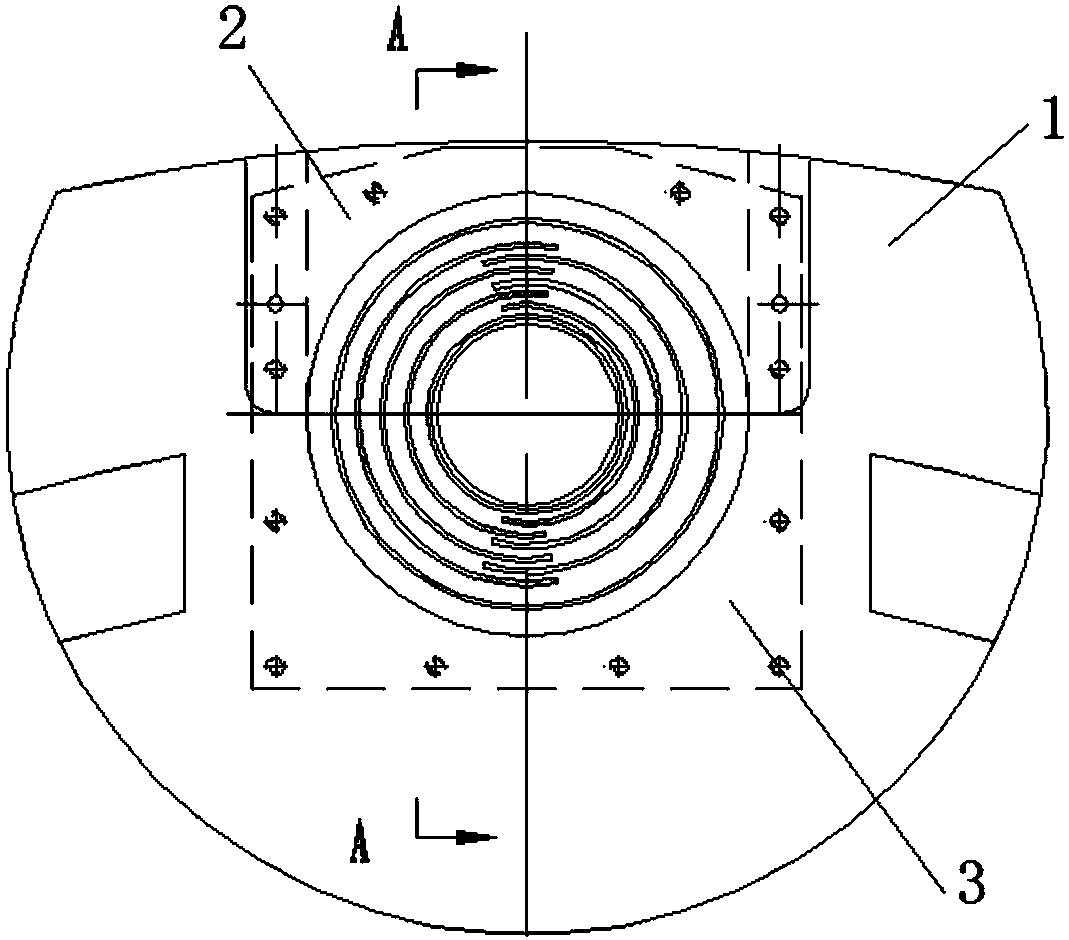

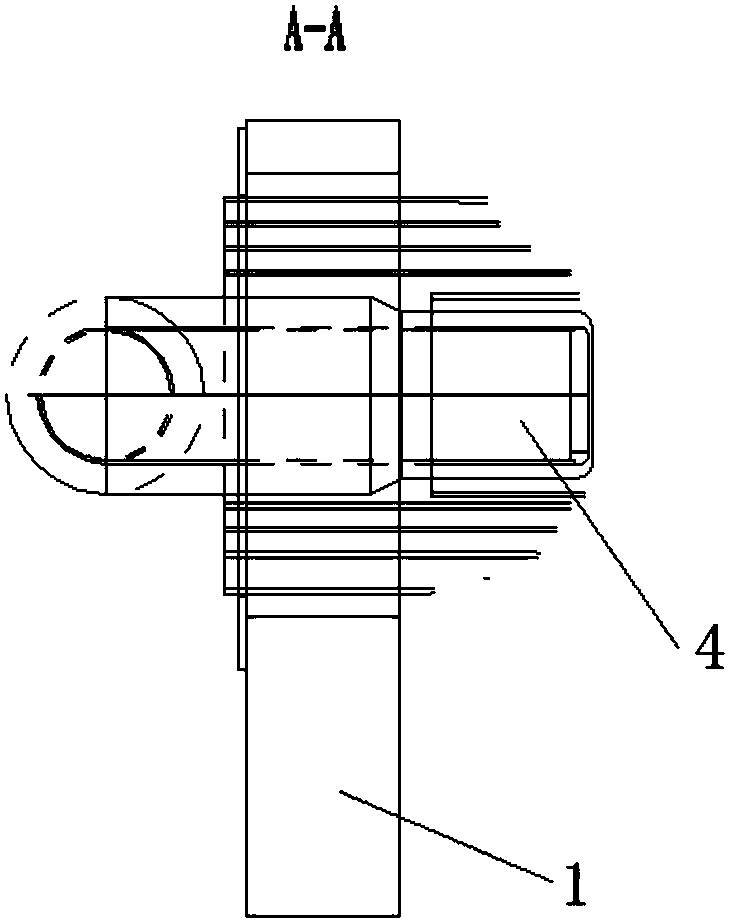

[0029] Such as Figure 1A , 1B As shown, the transformer of the present invention has a matching structure between the pressure plate and the outgoing line, which has a pressure plate and an oil seal plate 3. The pressure plate includes two parts: the pressure plate body 1 and the cushion block 2. Plate 3 is installed on the lower part of the pressing plate.

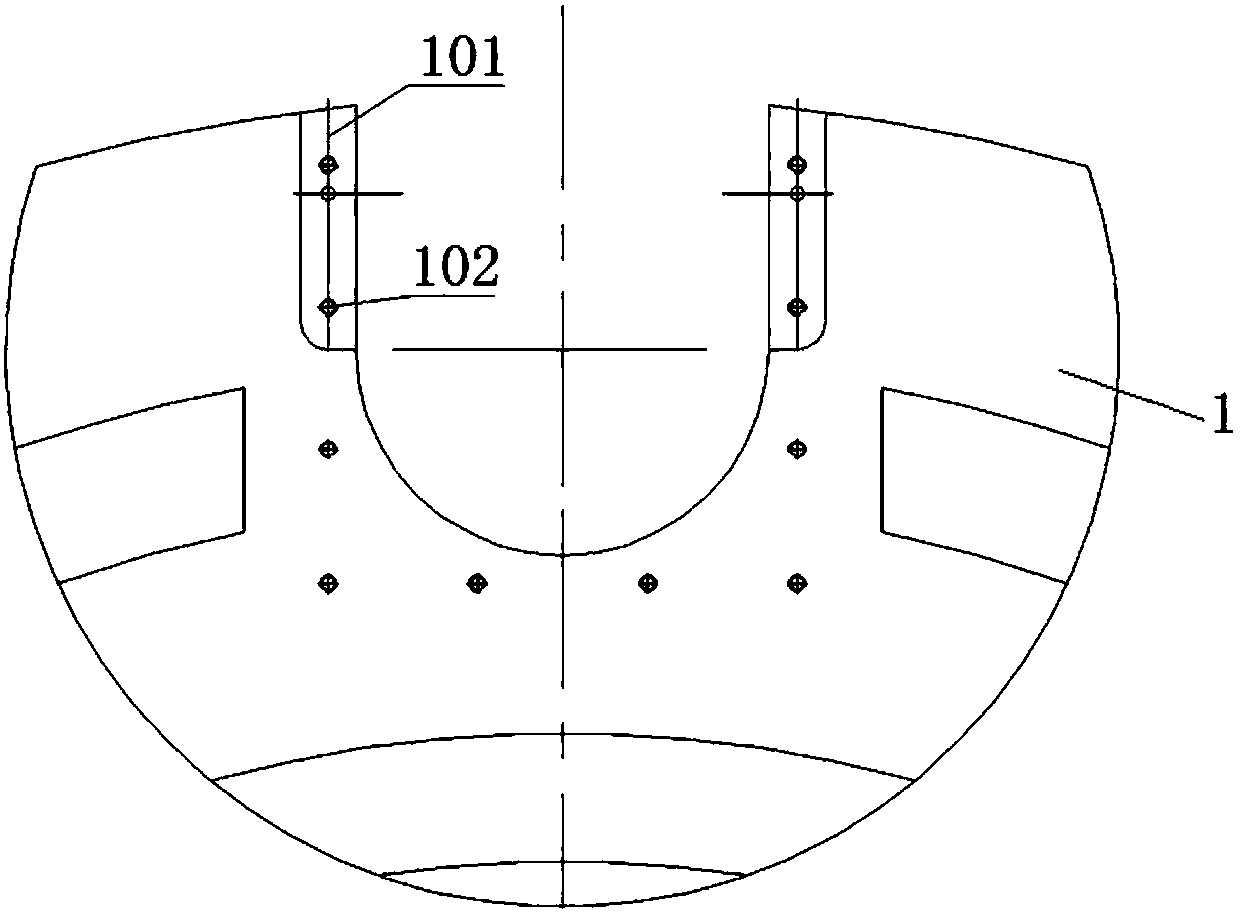

[0030] Such as figure 2 As shown, one side of the platen body 1 is provided with an open notch, the edge of the notch is the installation side, and the notch is in an inverted ladder shape in the thickness direction; in this embodiment, the notch adopts a U-shaped mouth, and the spacer 2 passes through Cardboard pins are installed on both sides of the U-shaped mouth.

[0031] Such as Figure 3A , 3B As shown, the spacer 2 has an opening abutting with the notch of the pressure plate body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com