Central beam assembly applicable to railway wagon having large weight-concentrating capability

A technology for railway wagons and capacity, which is applied to railway car body components, chassis, transportation and packaging, etc., and can solve the problems of small space for side beams, great impact on train inspection work efficiency, and inconvenience for train inspectors to enter under the car for inspection, etc. , to achieve the effects of improving the stress condition, uniform stress, improving quality and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

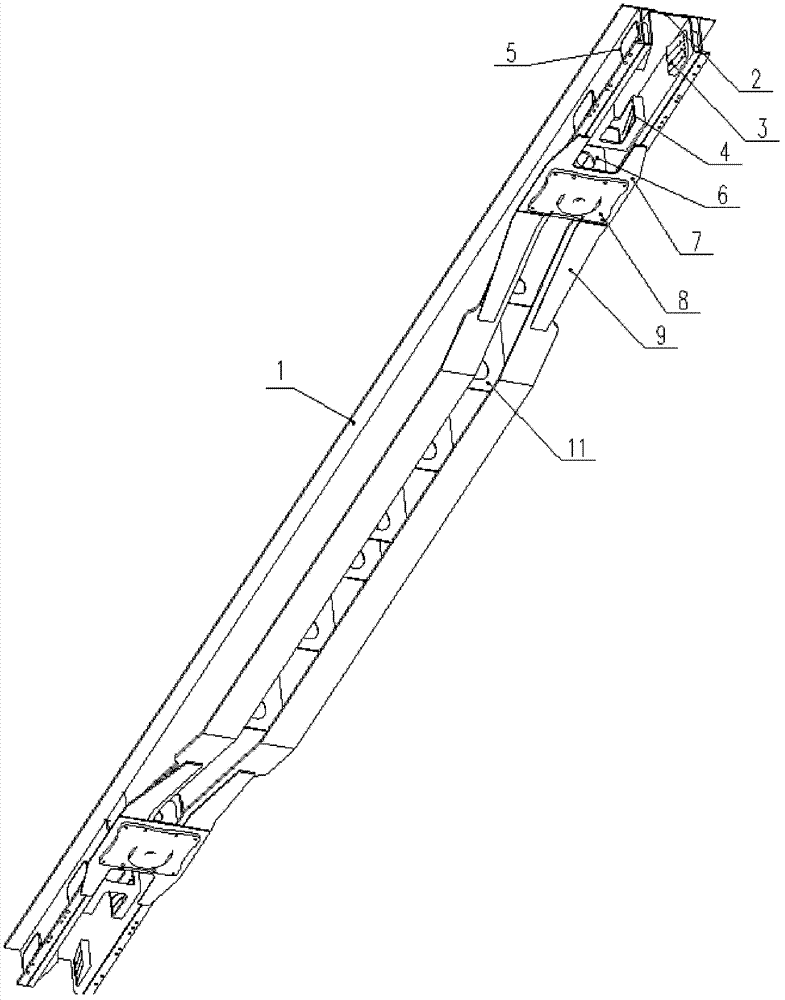

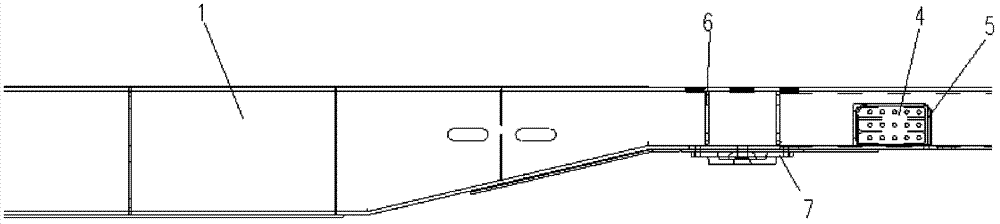

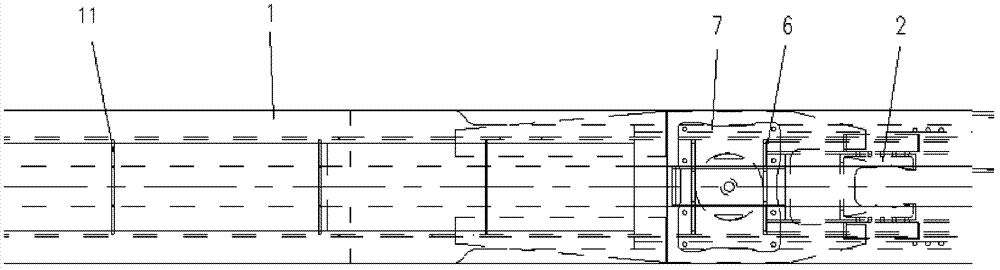

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1~3 As shown, the present invention includes: a fish-bellied center beam 1 made of two H-shaped steels, an inner draw beam 2 positioned in the webs at both ends of the center beam, a front slave plate seat 3 and a rear plate seat fixed on the inner draw beam. From the board seat 4 and the reinforcement beam 5 from the board seat hole, the pillow middle partition 6 and the center plate backing plate 7 located in the center beam web behind the inner traction beam 2, the upper center plate 8 and the pillow installed on the center plate backing plate Rear center plate reinforcement plate 9, and pillow center connecting plate 10 located between the upper wing edges of the center sill, center sill partition 11 located in the middle web of the center sill, upper cover plate 12 at the top of the center sill, and lower cover plate 13 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com