Cutting and grinding correcting device for rubber transmission belt

A technology of deviation correction device and transmission belt, which is applied in the direction of grinding workpiece support, grinding/polishing equipment, grinding machine, etc., which can solve the problem of low precision of tape width and size, and achieve the effect of high tape width precision and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

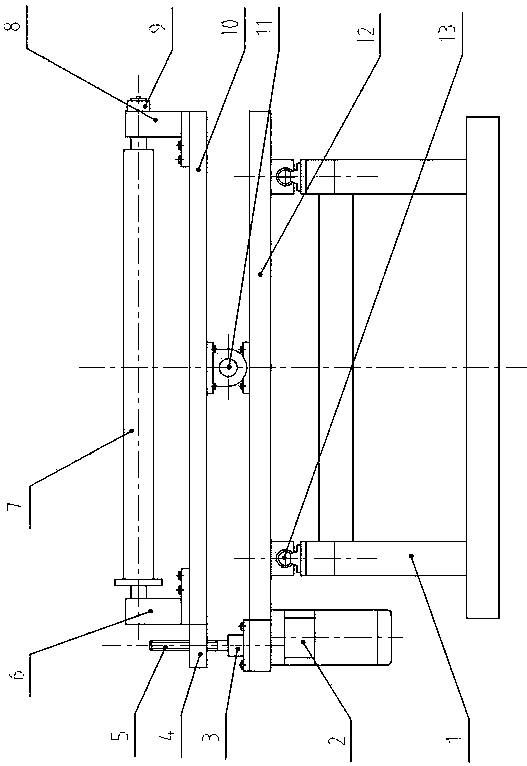

[0010] As shown in the figure, two rails 13 are installed on the rail support frame 1, and the rail sliding plate 12 is installed on the rails 13 and tensioned forward and backward. Its special feature is that the driven roller 7 is fixed on the support plate 10 by the left support frame 6 and the right support frame 8, and the hinge shaft device 11 is fixed with the support plate 10 and the track sliding plate 12. The power reduction motor 2 is installed on the side of the track sliding plate 12, and the adjustment screw nut 4 is installed on the support plate 10. The screw 5 is connected with the power reduction motor 2 through the bearing seat 3, the screw rotates, and the screw nut drives the left side of the driven roller Or adjust up and down on the right side, which solves the problem of correcting the rubber transmission belt during cutting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com