Output shaft clutch type gearbox facilitating gear shifting

An output shaft and clutch technology, applied in the direction of vehicle gearbox, transportation and packaging, components with teeth, etc., can solve the problems of difficult overall layout, shortened service life, and many related parts of the control mechanism, so as to reduce the manufacturing cost, The effect of improving reliability and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

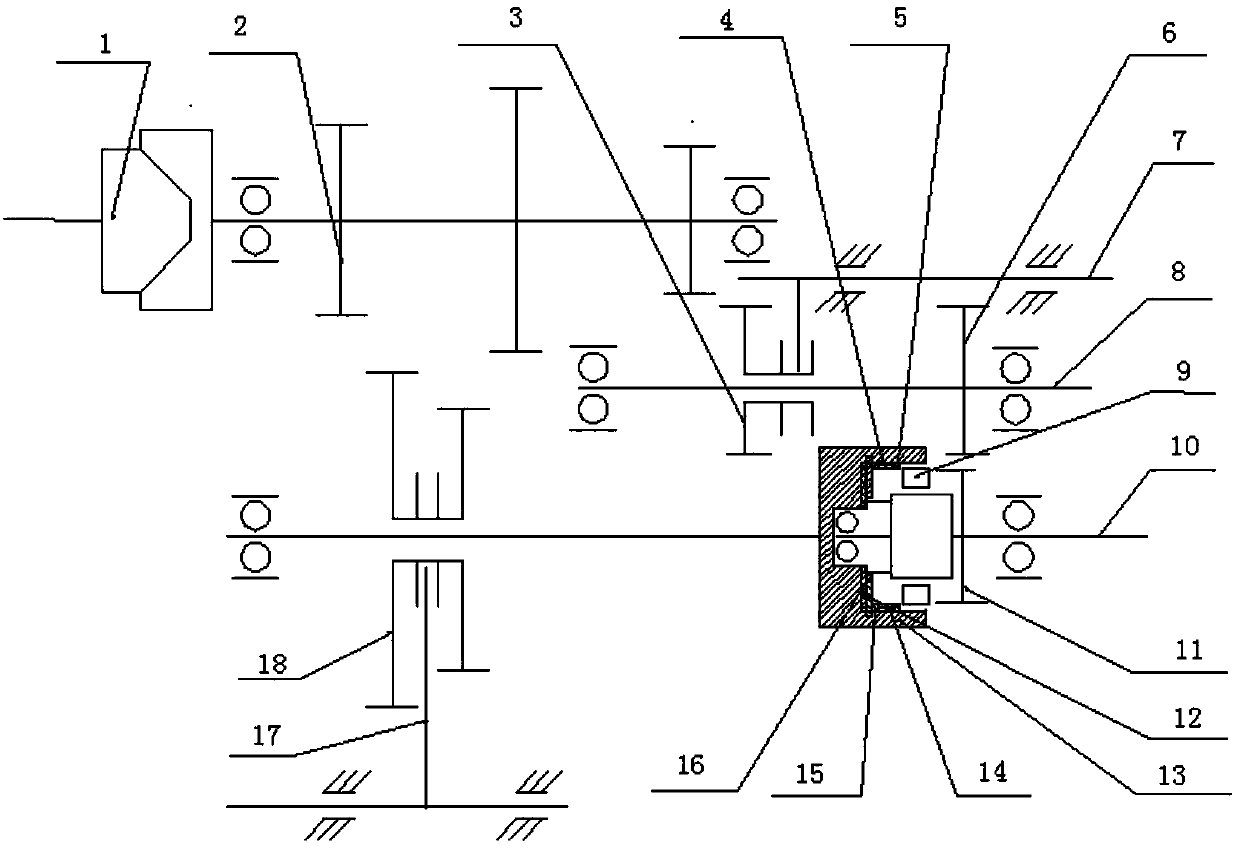

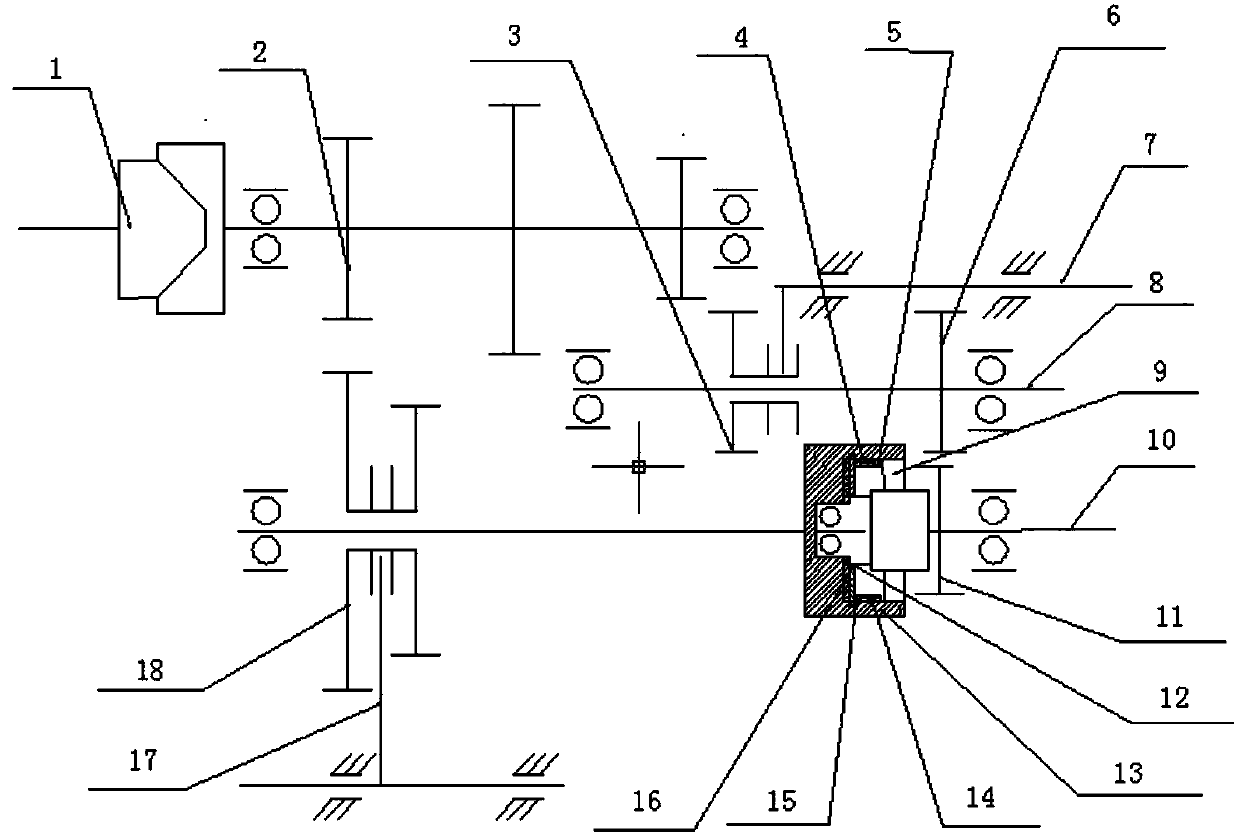

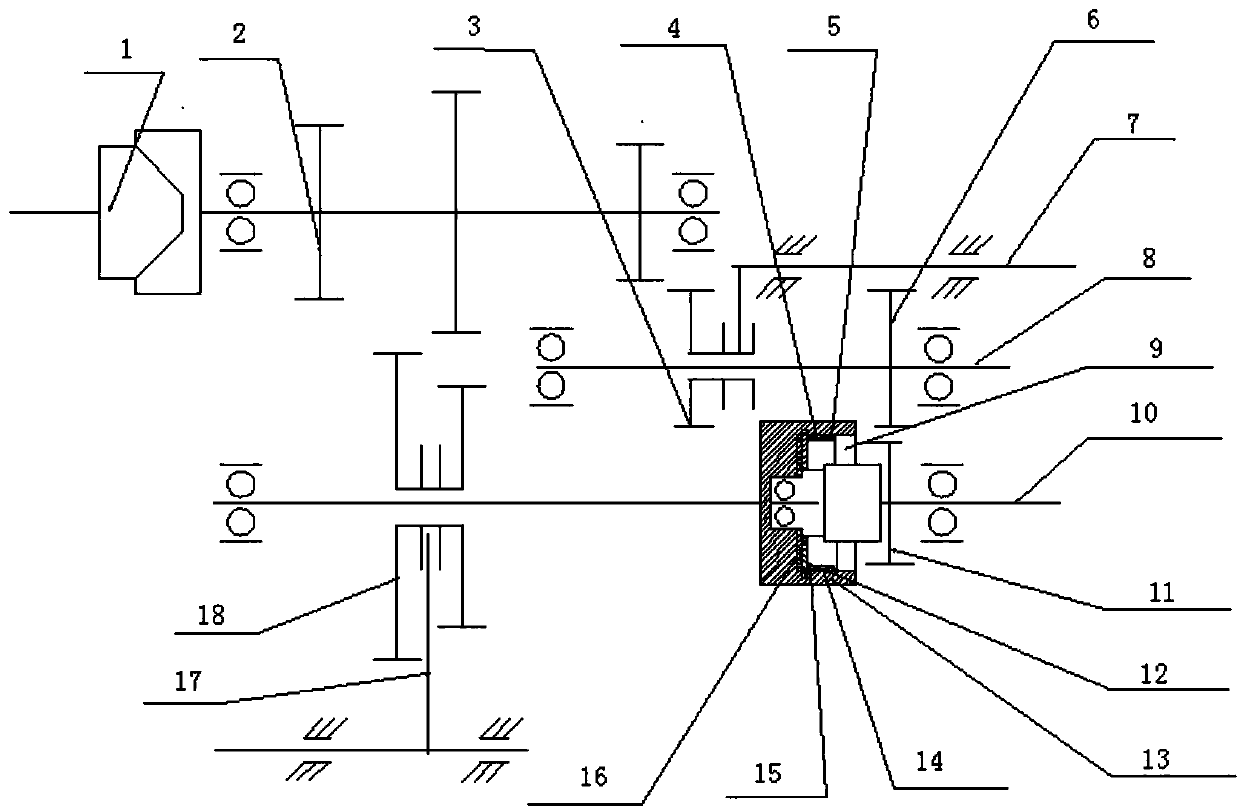

[0025] An output shaft clutch type gearbox for easy shifting, which consists of an input shaft, an input shaft clutch 1, an input shaft driving gear 2, an output shaft, a locking mechanism, an output shaft sliding gear set 18, a one-way clutch 9, and a reverse gear output Shaft 8, reverse gear sliding gear 3, reverse gear intermediate gear 6 and reverse gear output gear 11 are formed. An input shaft clutch is installed on the input end of the input shaft to combine and cut off the engine power. There is an input shaft driving gear, which is used to transmit power to the output shaft gear. The output shaft is composed of the front section 13 of the output shaft and the rear section 10 of the output shaft. The front section of the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com