Flow guide tunnel by utilizing permanent plug head section joint gate opening and plugging arrangement and method

A technology of diversion tunnels and plugs, which is applied in water conservancy projects, hydroelectric power stations, hydroelectric power generation, etc., can solve the high risk of water blocking safety at the entrance of the diversion tunnel, increase the risk of the import structure during the blocking period, and the geology of the project import. Complex conditions and other problems, to achieve the effect of eliminating the safety risk of water retention, optimizing the arrangement and method of plugging, and improving the safety of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

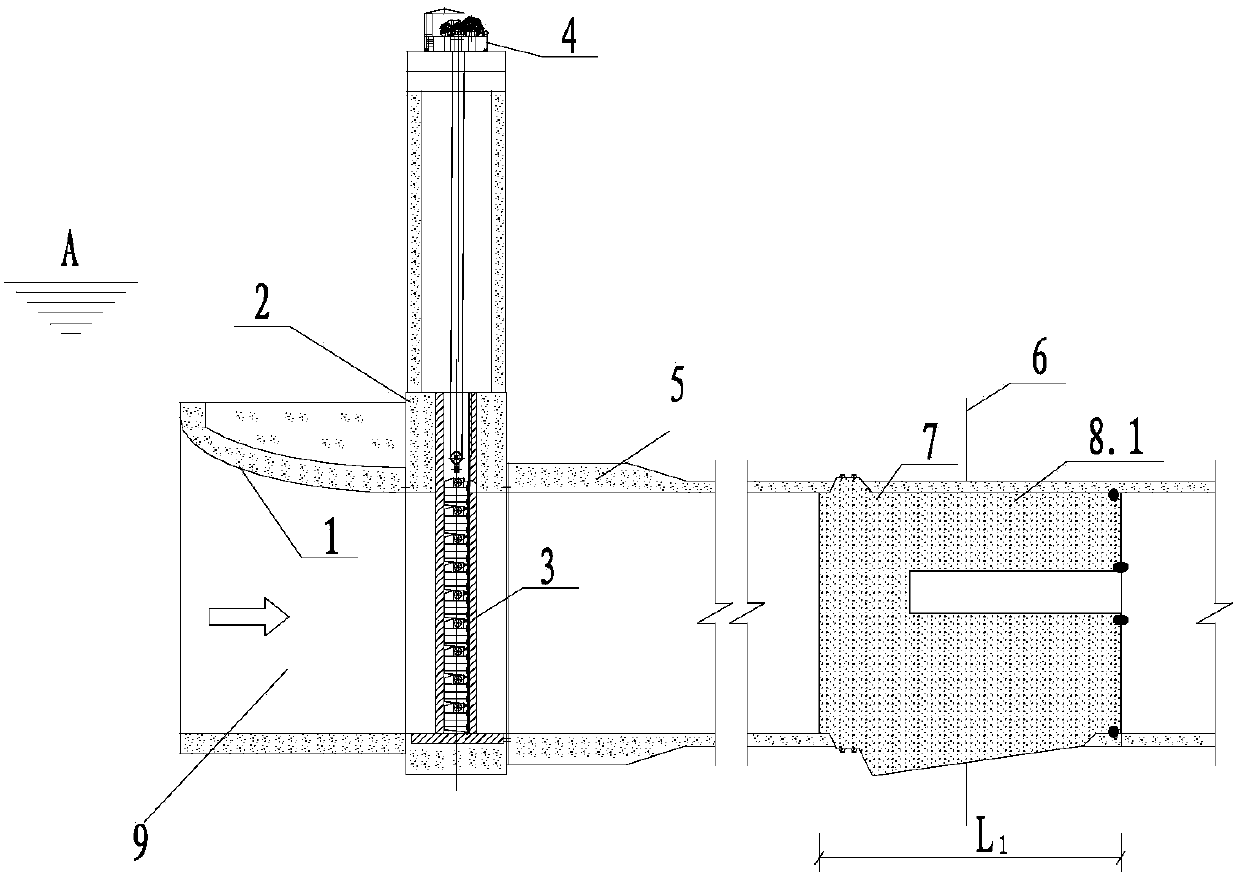

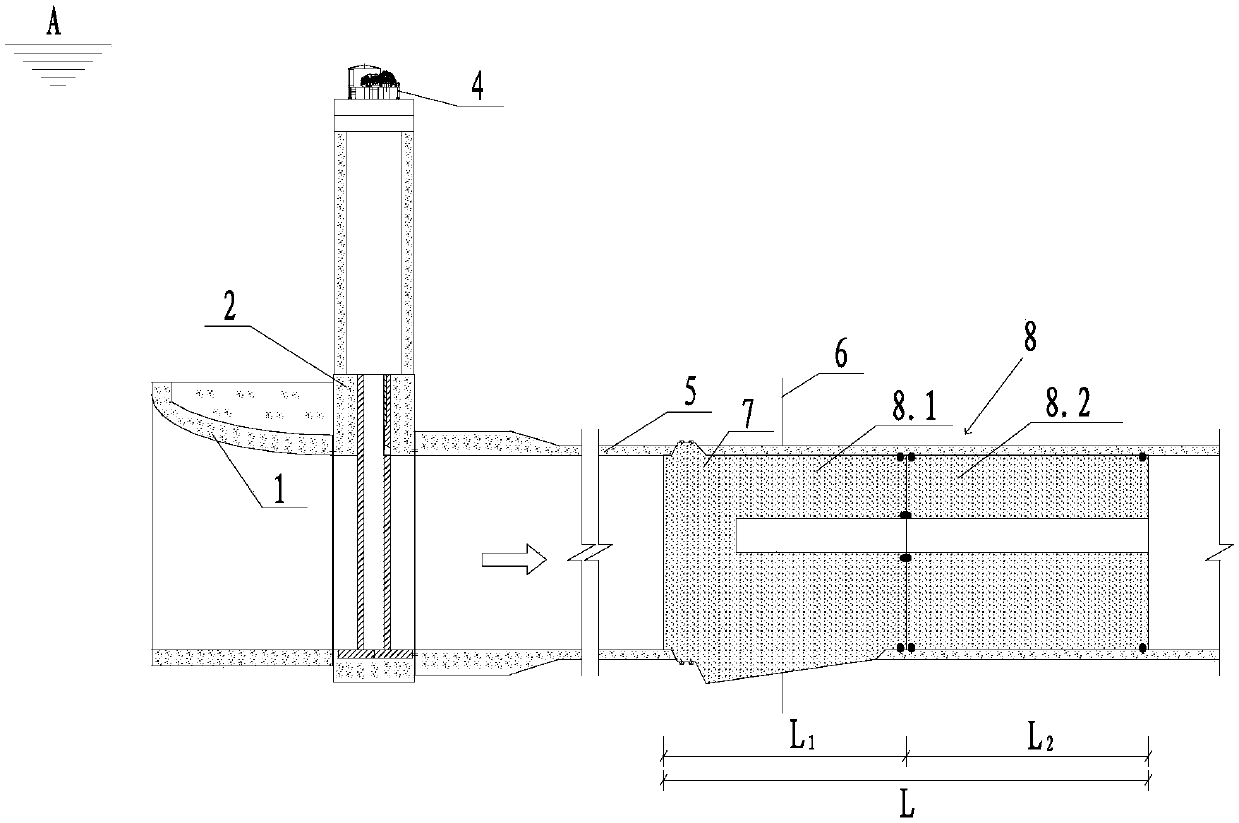

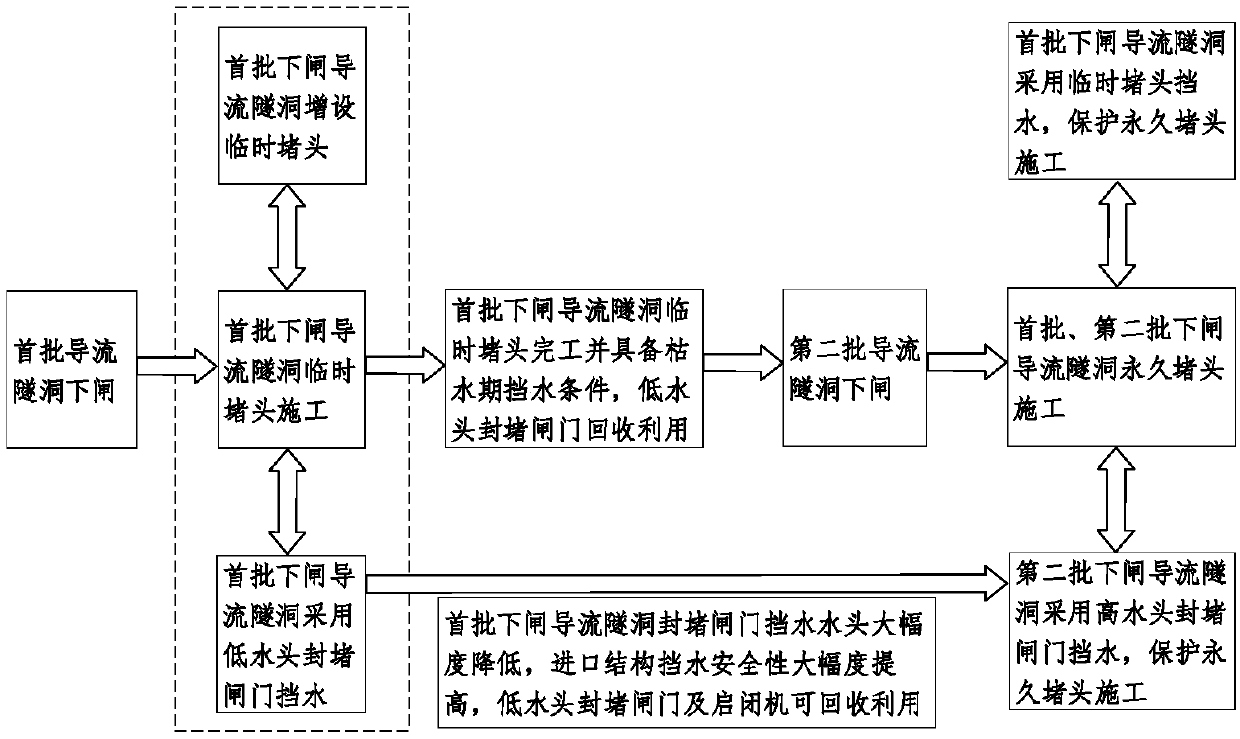

[0033] refer to Figure 1-2 Shown: the diversion tunnel utilizes the first section of the permanent plug joint gate to be closed and arranged. It includes a plurality of diversion tunnels 9 to form a diversion tunnel group, and the diversion tunnel group includes two batches of the diversion tunnels respectively The diversion tunnel 9, the diversion tunnel 9 of the first batch of lower gates includes the diversion tunnel entrance section 1 and the diversion tunnel body 1.1; the diversion tunnel entrance section 1 is provided with a low water head blocking gate 3. A water inlet tower 2 is installed at the entrance section 1 of the diversion tunnel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com