Prestressed fiber cloth tensioning system

A fiber cloth and prestressing technology, applied in the field of prestressed fiber cloth tensioning system, can solve the problems of small prestress and inapplicability, and achieve the effect of easy transportation, simple structure and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

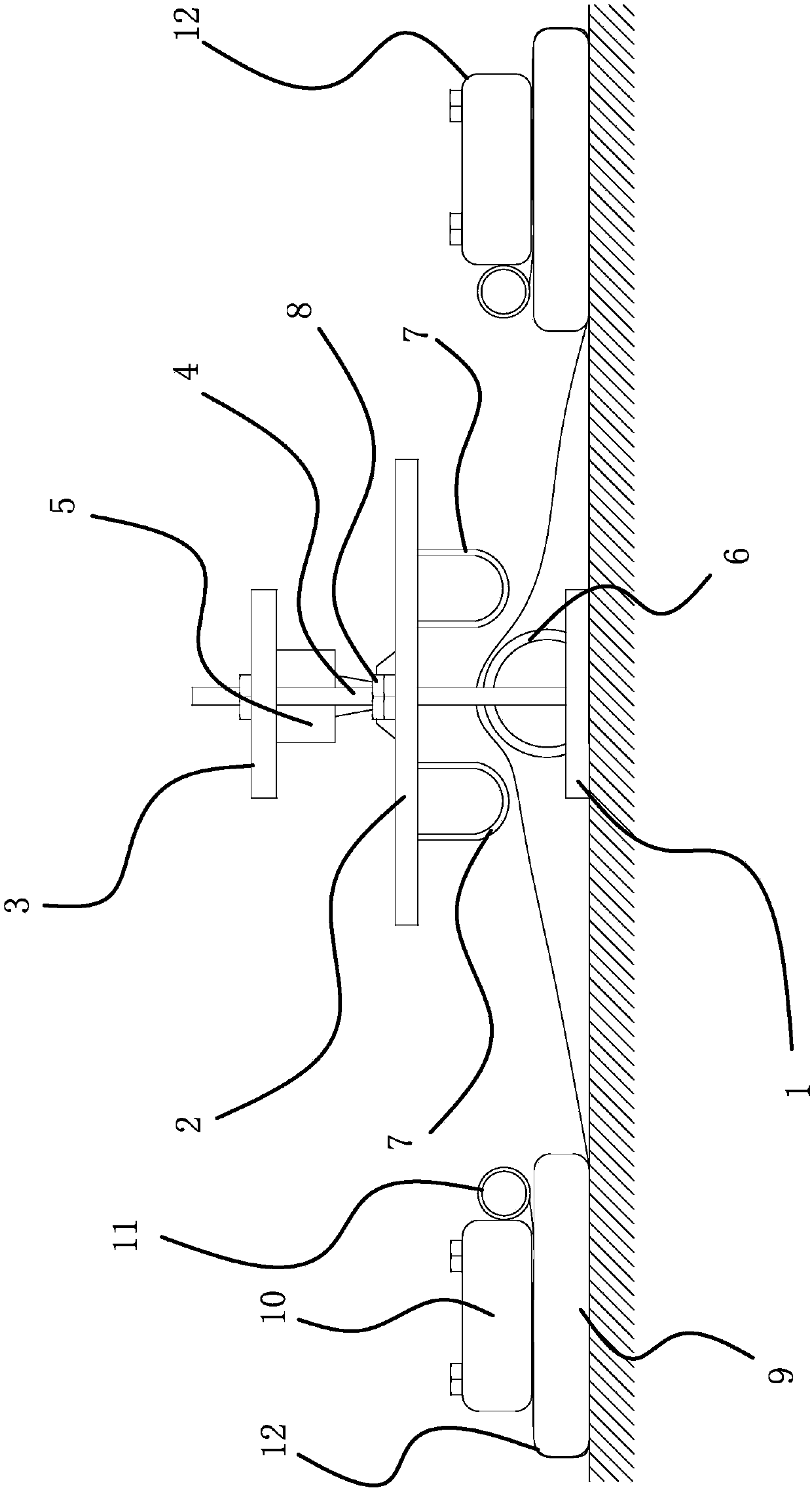

[0022] like figure 1 , figure 2 , image 3 As shown, the prestressed fiber cloth tensioning system includes a tension end anchor and two fixed end anchors, and the tension end anchor is located between the two fixed end anchors.

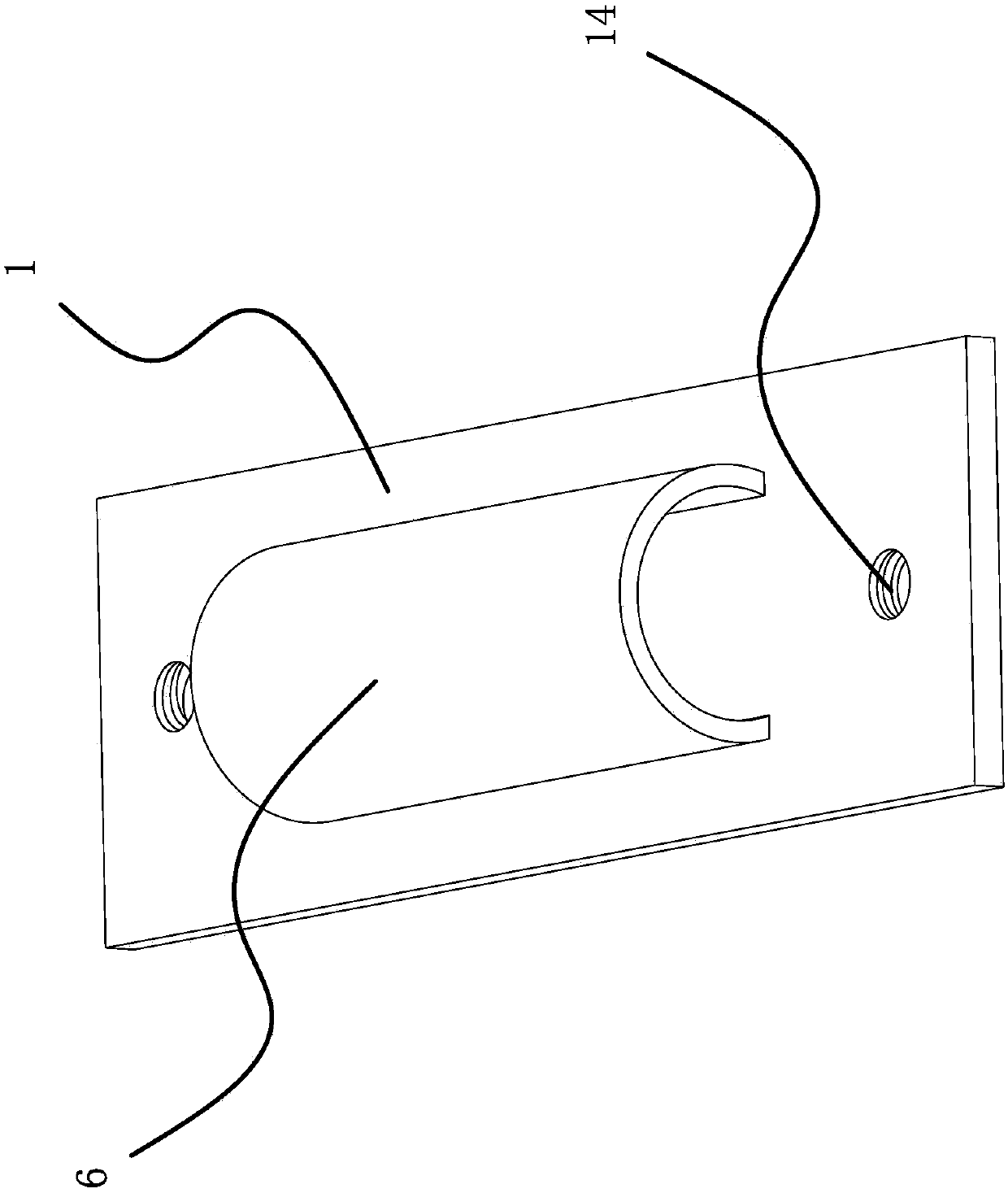

[0023] The tension end anchor includes a tension bottom plate 1, a tension pressure plate 2, an upper top plate 3, a screw 4 and a jack 5. The tension bottom plate 1 is fixed on the concrete through the screw rod 4, and the upper end surface of the tension bottom plate 1 has an upwardly convex shape. The arch-shaped arc portion 16, the lower end surface of the tension plate 2 has two downwardly protruding arch-shaped arc portions 2 7, and the arc portion 1 6 can be embedded between the two arc portion 7 In the gap, the jack 5 is fixed on the lower end surface of the upper top plate 3, the lower end of the jack 5 is against the upper end surface of the tension platen 2, and the screw 4 passes through the upper top plate 3, the tension platen 2 and ...

Embodiment 2

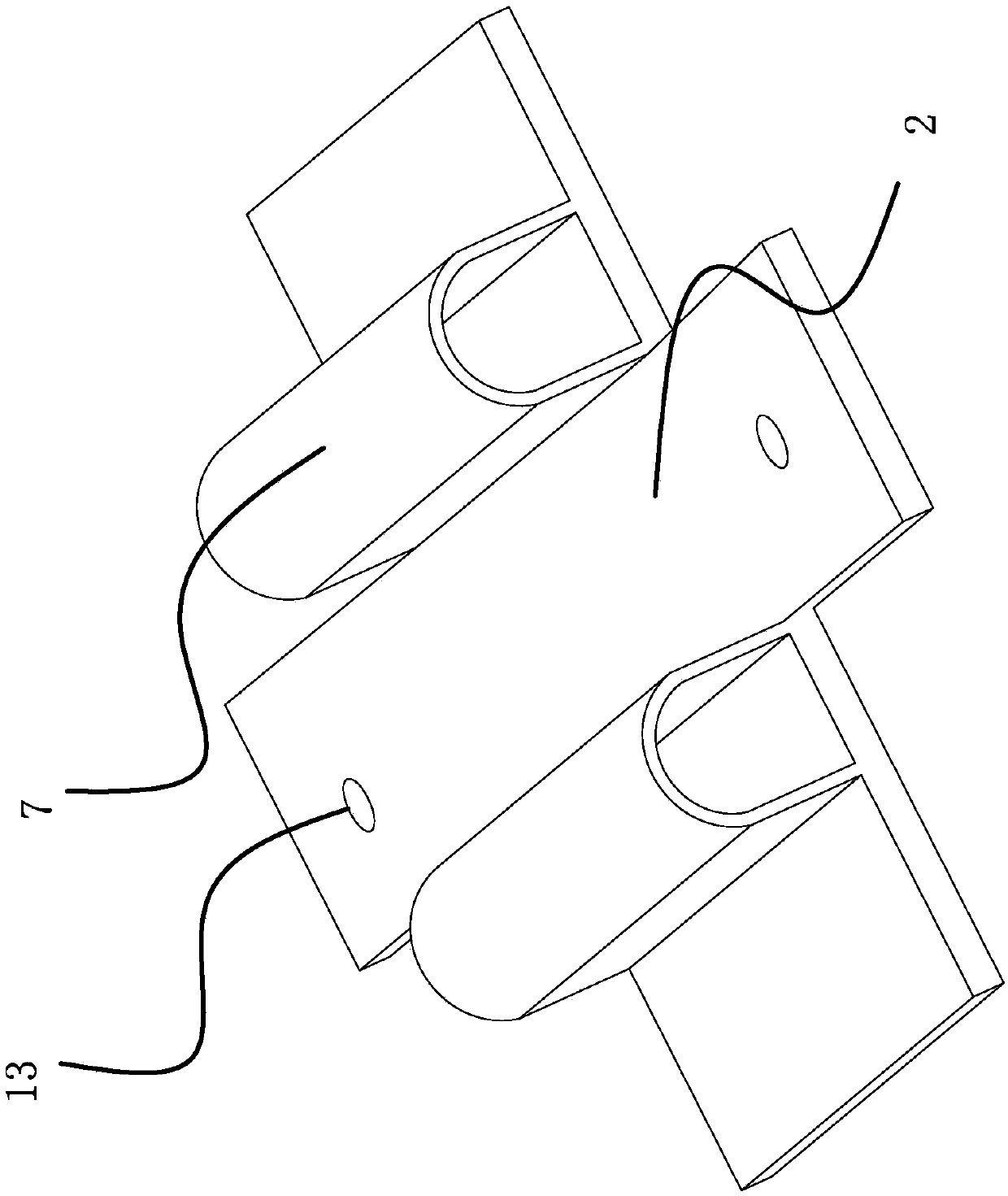

[0028] Reel 11 and prestressed fiber cloth are bonded firmly by glue, as Figure 4 As shown, two reels 11 are arranged on one side of the fixed platen 10, and one reel 11 is arranged on the other side, and there are iron bars between the two reels 11, and the prestressed fiber cloth is wound around the fixed base plate 9, Reel 11, iron bar, reel 11, fixed platen 10, reel 11, this winding mode structure is firmer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com