Precast beam wet joint diaphragm plate variable space operation platform and manufacturing method thereof

A technology of working platform and variable space, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of difficulty in guaranteeing construction quality, difficulty in supporting and erecting, and high construction costs, so as to ensure the squareness of the bottom space and prevent falling The bottom space is square and easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

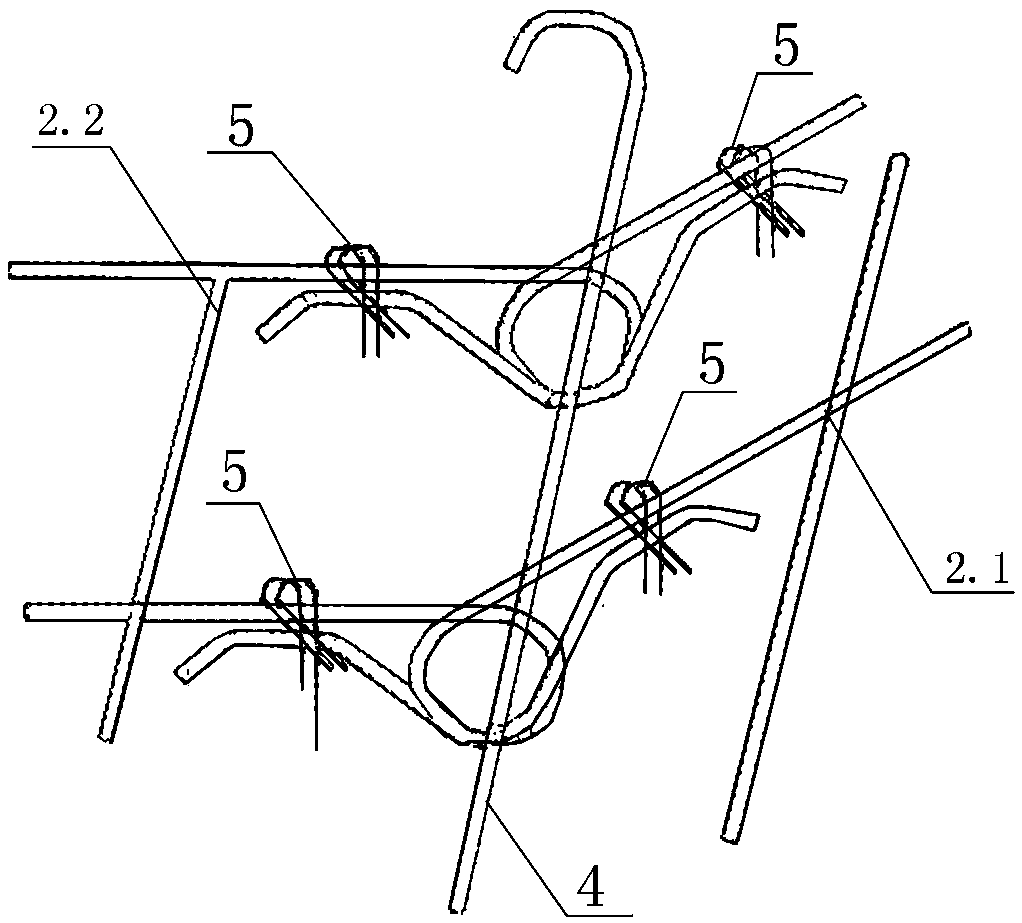

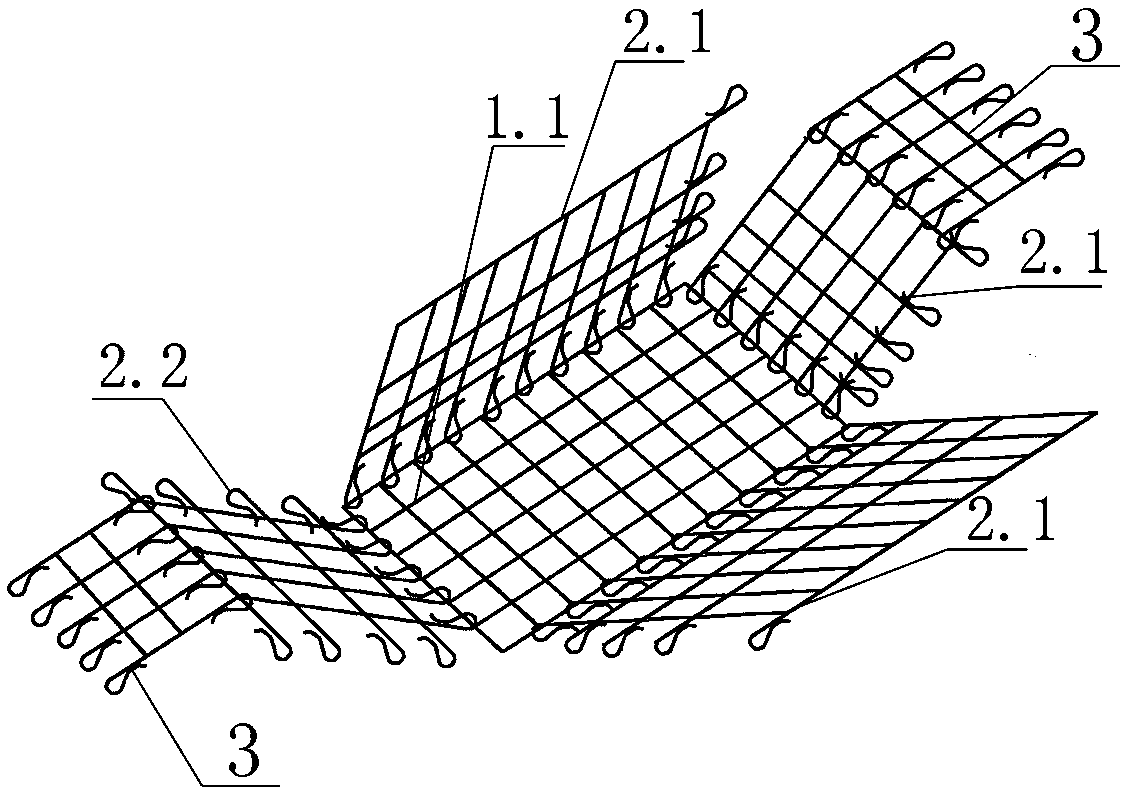

[0038] Such as Figure 1-4 As shown, this kind of prefabricated beam wet joint diaphragm variable space work platform is set at the joint position of two adjacent prefabricated beams for the construction of wet joint; it includes base plate structure 1, enclosure structure 2 and connecting member 3; the bottom plate structure 1 has one, which is horizontally arranged at the bottom of the work platform; the enclosure structure 2 is arranged along the edge of the bottom plate structure 1, and together with the bottom plate structure 1 forms a box-shaped structure; the enclosure structure 2 is enclosed by at least two first enclosure structure units 2.1 and one second enclosure structure unit 2.2, wherein, between two adjacent first enclosure structure units 2.1 Between the first enclosure structure unit 2.1 and the second enclosure structure unit 2.2 are detachable connections; between the bottom edge of the first enclosure structure unit 2.1 and the bottom plate structure 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com