Swing electric arc furnace door

An electric arc furnace, swing-type technology, applied in the field of electric arc furnace steelmaking, can solve the problems of electric arc furnace smelting power consumption increase, reduce auxiliary energy input, cold air entry, etc., to facilitate molten pool stirring and improve production efficiency , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

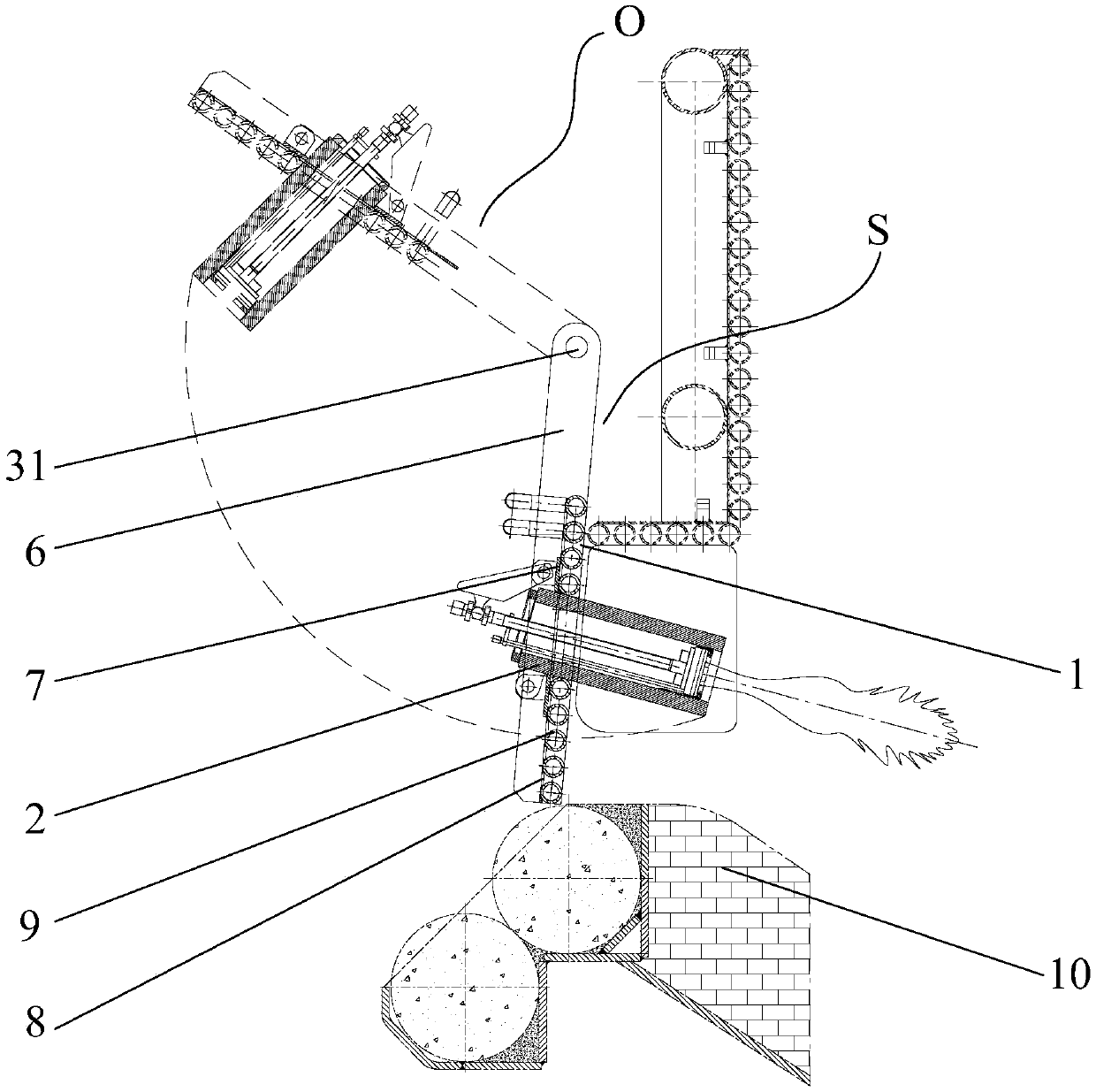

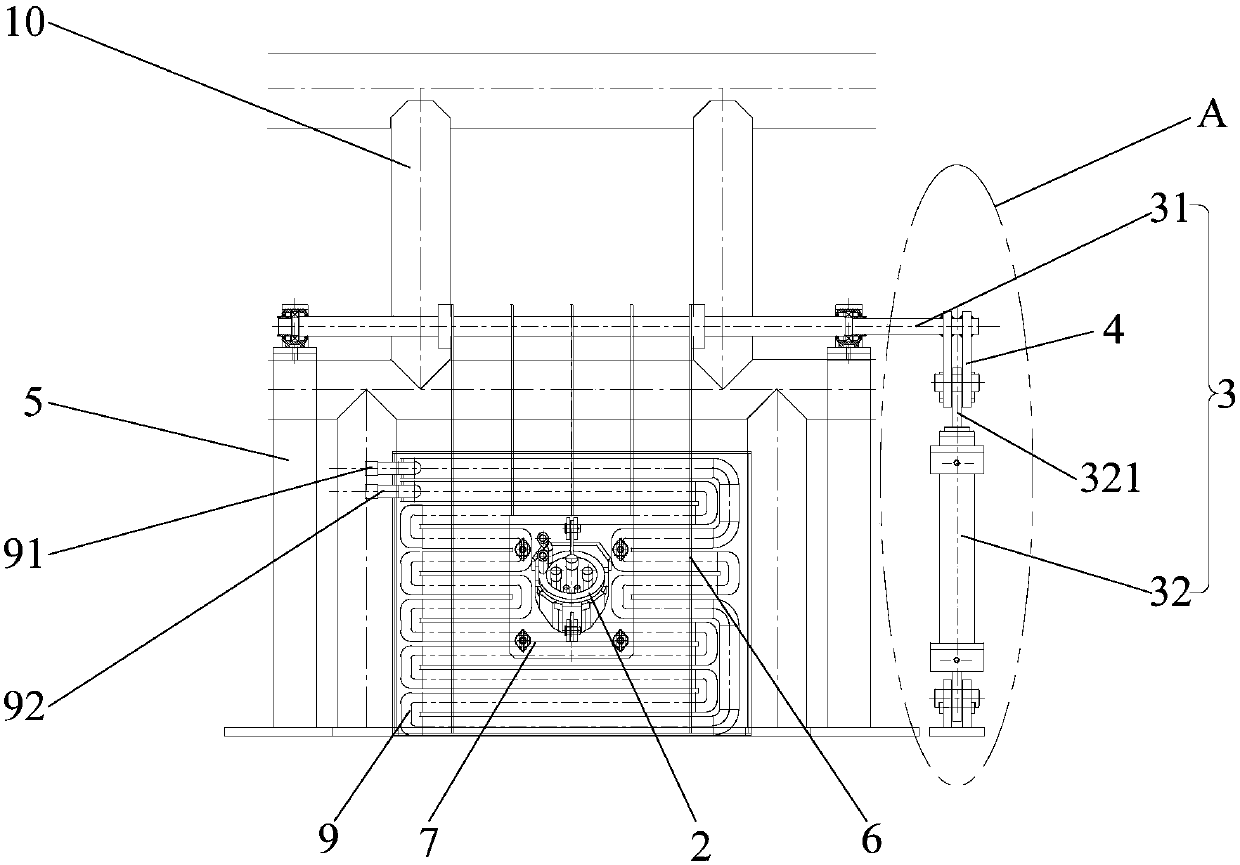

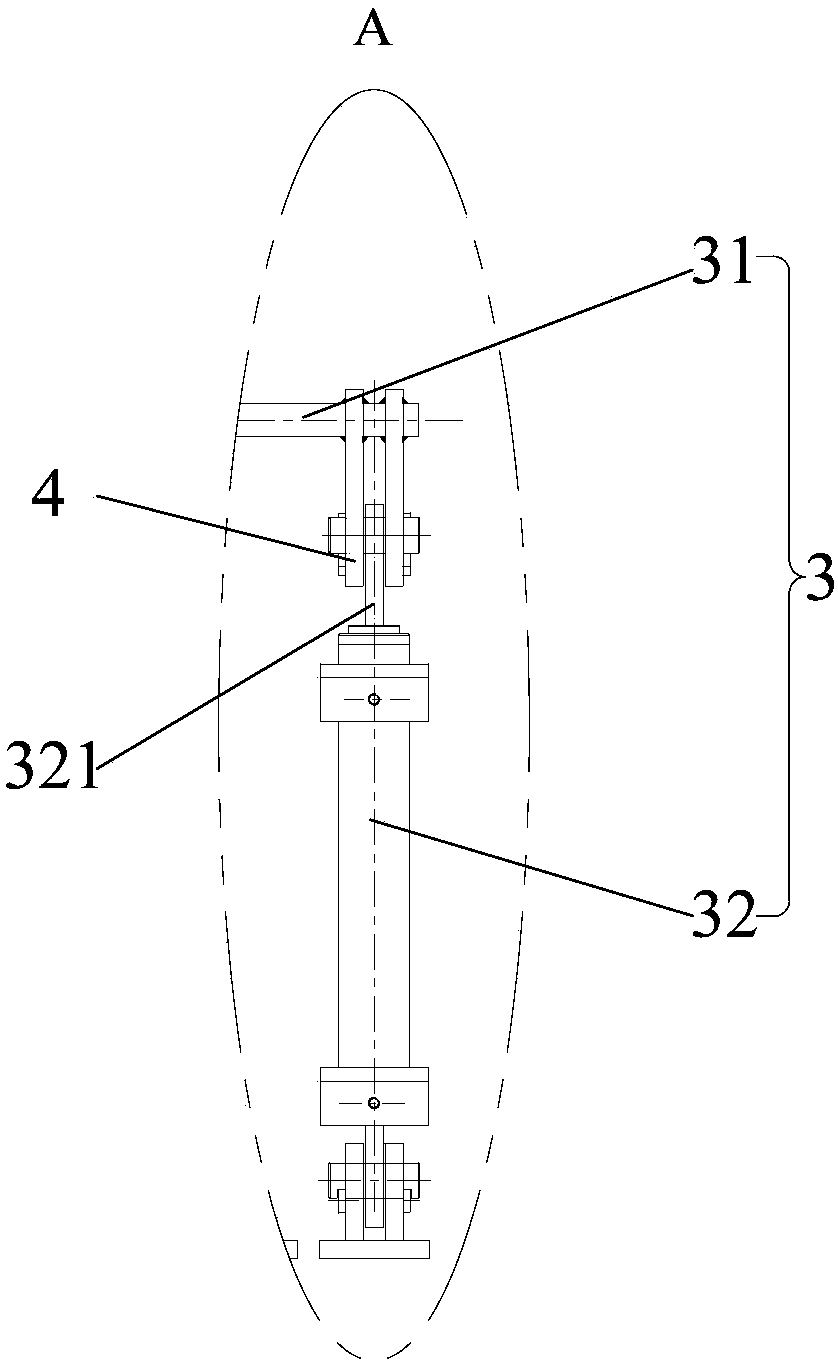

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a swing-type electric arc furnace door, which can be rotatably installed on the electric arc furnace. Lance 2, the nozzle of oxygen lance 2 faces the inner center of the electric arc furnace, so that oxygen is injected into the furnace, the middle through hole of the nozzle of oxygen lance 2 is the main oxygen injection hole, and the outwards are successively natural gas ring holes and oxygen ring holes, so that The oxygen lance 3 can realize the burner function and the clustered oxygen flow function, and the external medium connection of the oxygen lance 2 includes the main oxygen pipeline, natural gas pipeline, epoxy gas pipeline, cleaning oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com