Injection valve, exhaust-gas aftertreatment system

A technology of exhaust gas post-treatment and injection valve, which is applied in the direction of exhaust treatment, valve lift, control valve, etc., can solve the problems that the functional capacity of the injection valve can no longer be guaranteed, and achieve the effect of improving ice pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

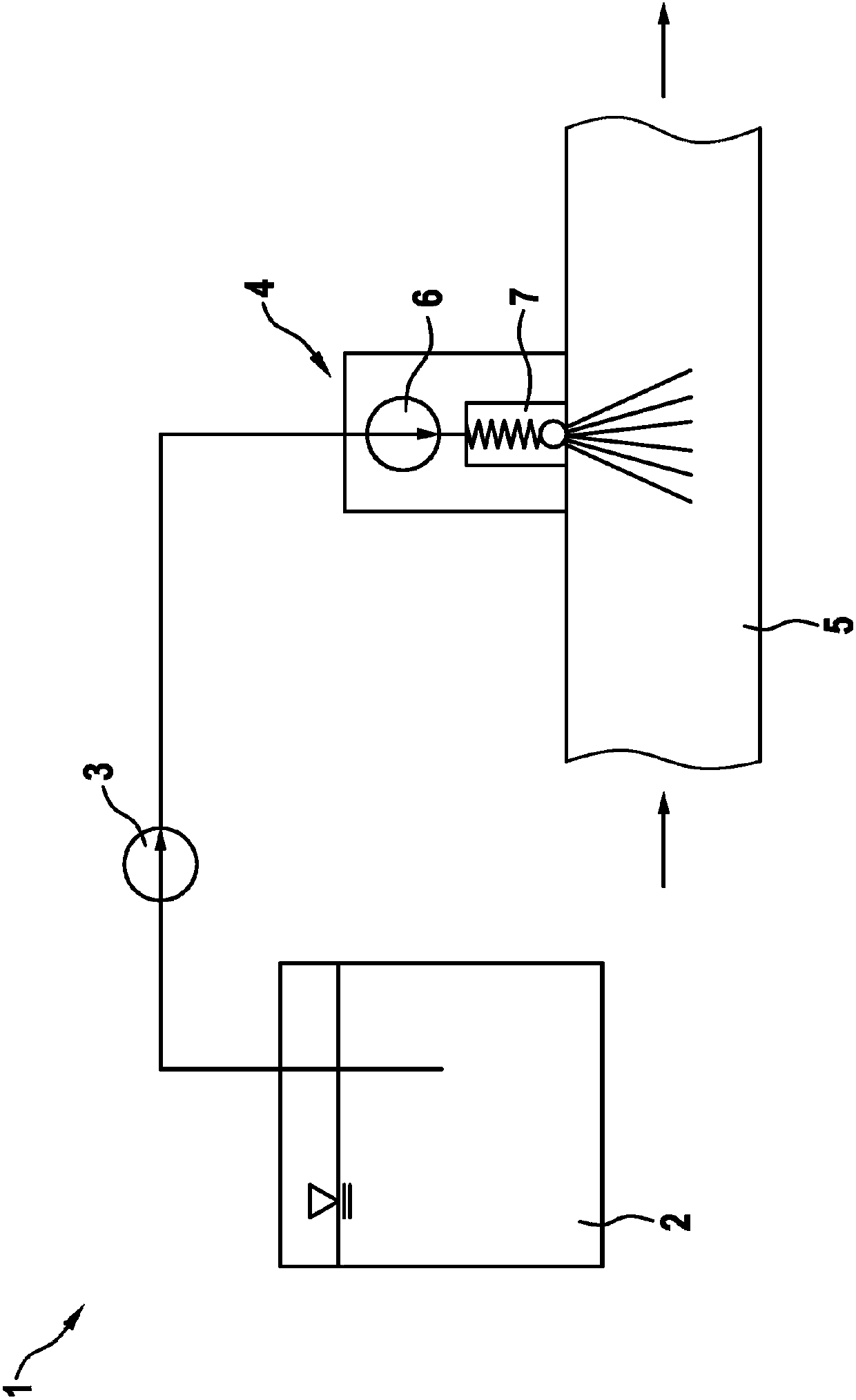

[0016] figure 1 An exhaust gas aftertreatment system 1 for a motor vehicle, not shown in detail here, is shown in schematic form. The exhaust gas aftertreatment system 1 has a tank 2 for storing and supplying a liquid reducing agent or exhaust gas aftertreatment agent, in particular an aqueous urea solution. Liquid reducing agent can be extracted from tank 2 by means of delivery pump 3 and delivered to injection valve 4 . The injection valve 4 is associated with an exhaust gas line 5 of an internal combustion engine of the motor vehicle (not shown in detail here) in order to inject reducing agent into the exhaust gas of the internal combustion engine. The injection valve 4 is designed here as a pump-nozzle unit, which includes an integrated delivery device 6 , in particular a pump, and a pressure-controlled valve 7 , shown here only in simplified form.

[0017] Due to the possibly long suction lines and the high temperatures in the exhaust pipe, it is advantageous to provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com