Laptop rotary shaft cavity and manufacturing technology thereof

A technology for notebook computers and manufacturing processes, applied in pivot connection, digital processing power distribution, etc., can solve the problems of inability to meet diverse needs, difficult to meet aesthetic requirements, large core draft angle, etc. Flawless, stable rotation, deep welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

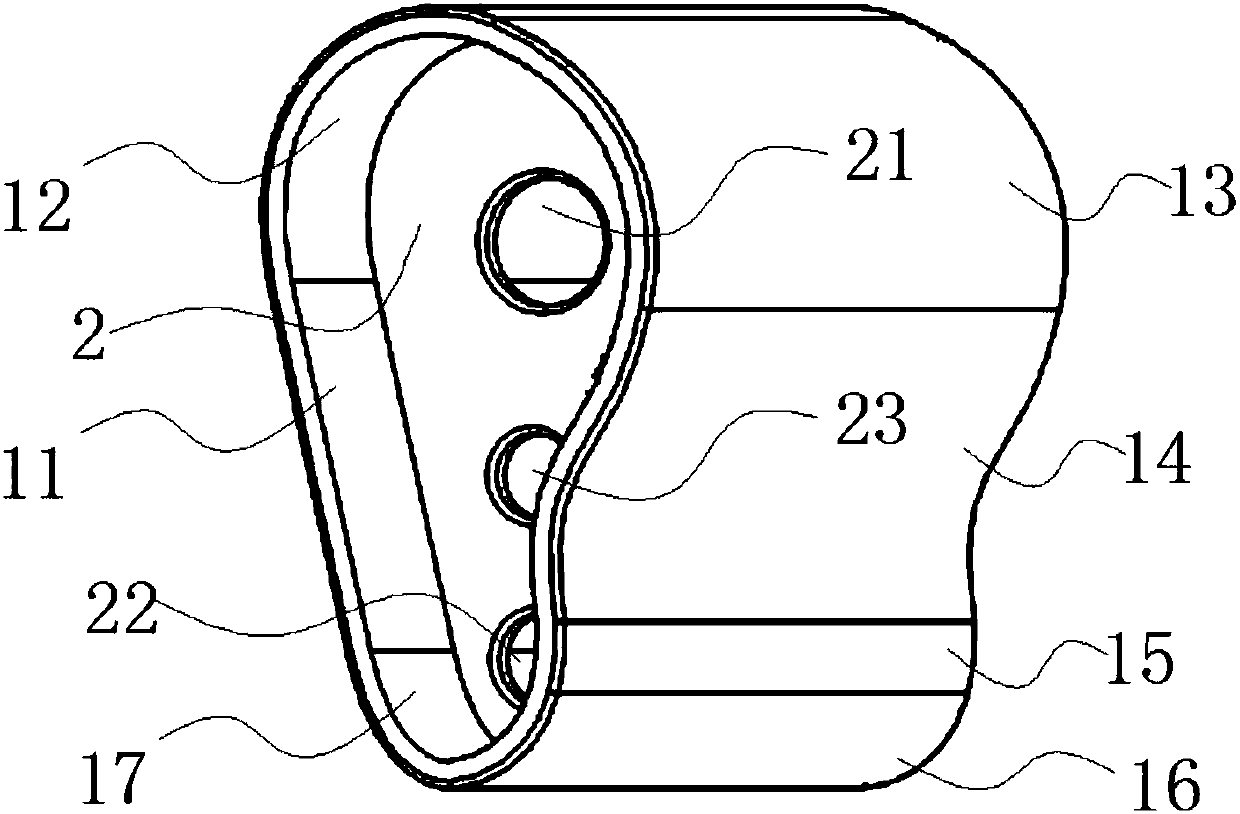

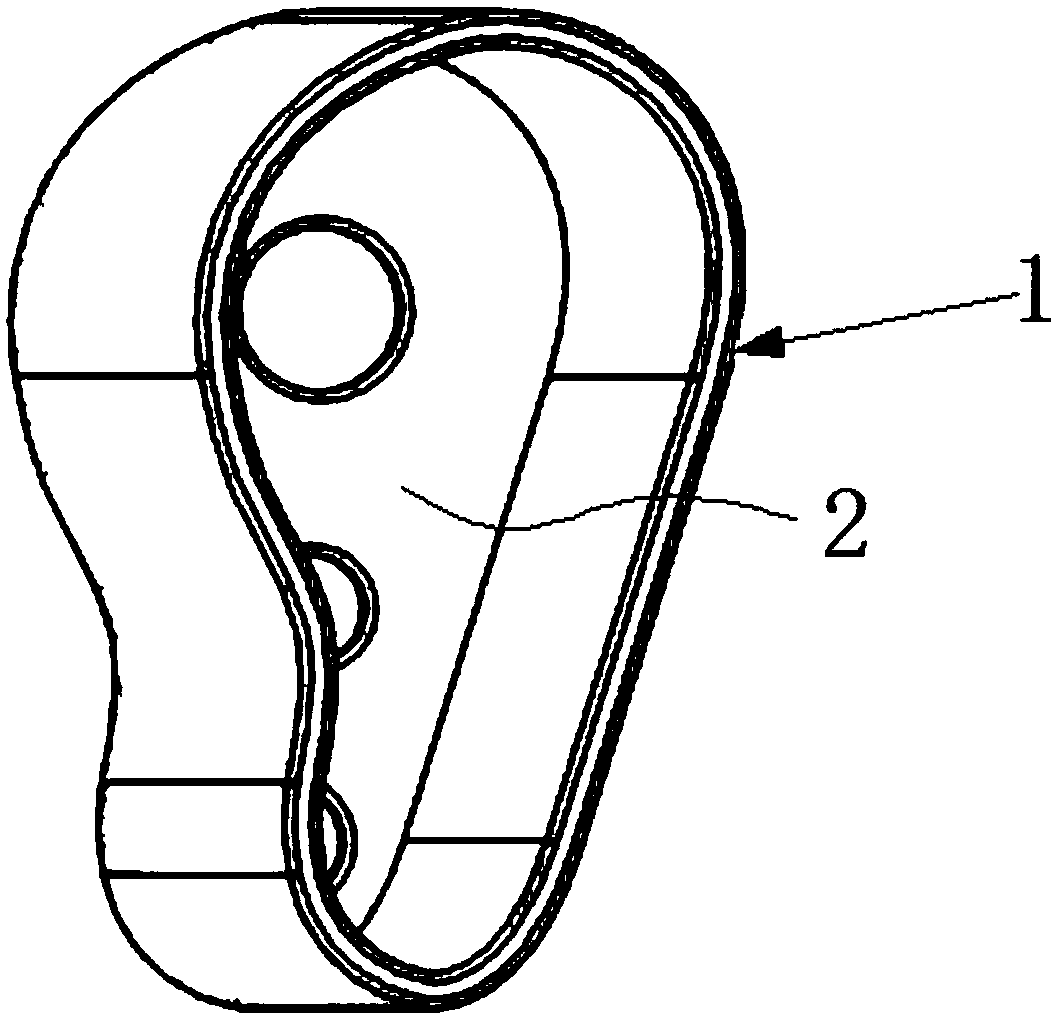

[0053] Embodiment: a kind of notebook computer shaft chamber, such as Figure 1 to Figure 6 As shown, it includes a cylindrical cavity 1 and a baffle 2 arranged in the cylindrical cavity, an accommodating space is formed in the cylindrical cavity, and the baffle is connected with the inner wall of the cylindrical cavity by spot welding And the baffle is perpendicular to the inner wall of the cylindrical cavity;

[0054] The cylindrical cavity includes seven successively connected surfaces, which are respectively a first plane 11, a first convex arc surface 12, a second convex arc surface 13, and a third arc surface first convex and then concave. 14. The fourth convex arc surface 15, the fifth convex arc surface 16 and the sixth arc surface 17 are convex, the seven surfaces are integrally formed, and the first plane is opposite to the second arc surface , the first arc surface, the second arc surface, the third arc surface, the fourth arc surface, the fifth arc surface and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com