City tunnel drilling and milling machinery combination non-exploding excavation technique

A tunneling and mechanical technology, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve problems such as instability, cracking of structures, and great influence of human activities, so as to ensure stability and integrity, low damage strength, and reduce surface settlement. and tunnel collapse risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

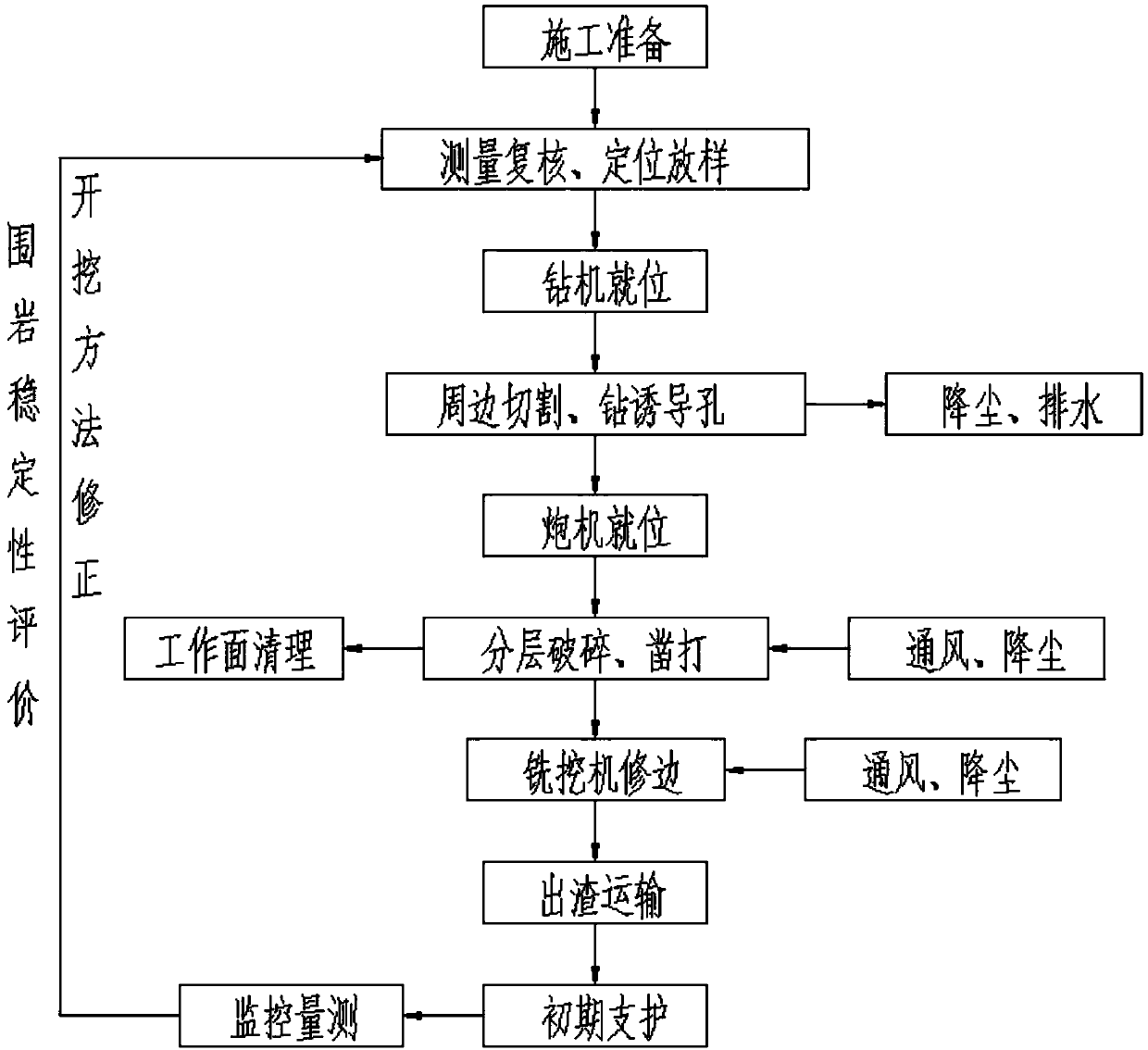

[0030] Such as figure 1 -Shown in 7, a kind of urban tunnel drilling and milling machine combined non-explosive excavation process is carried out in the following steps:

[0031] 1. Determine the height and length of the steps

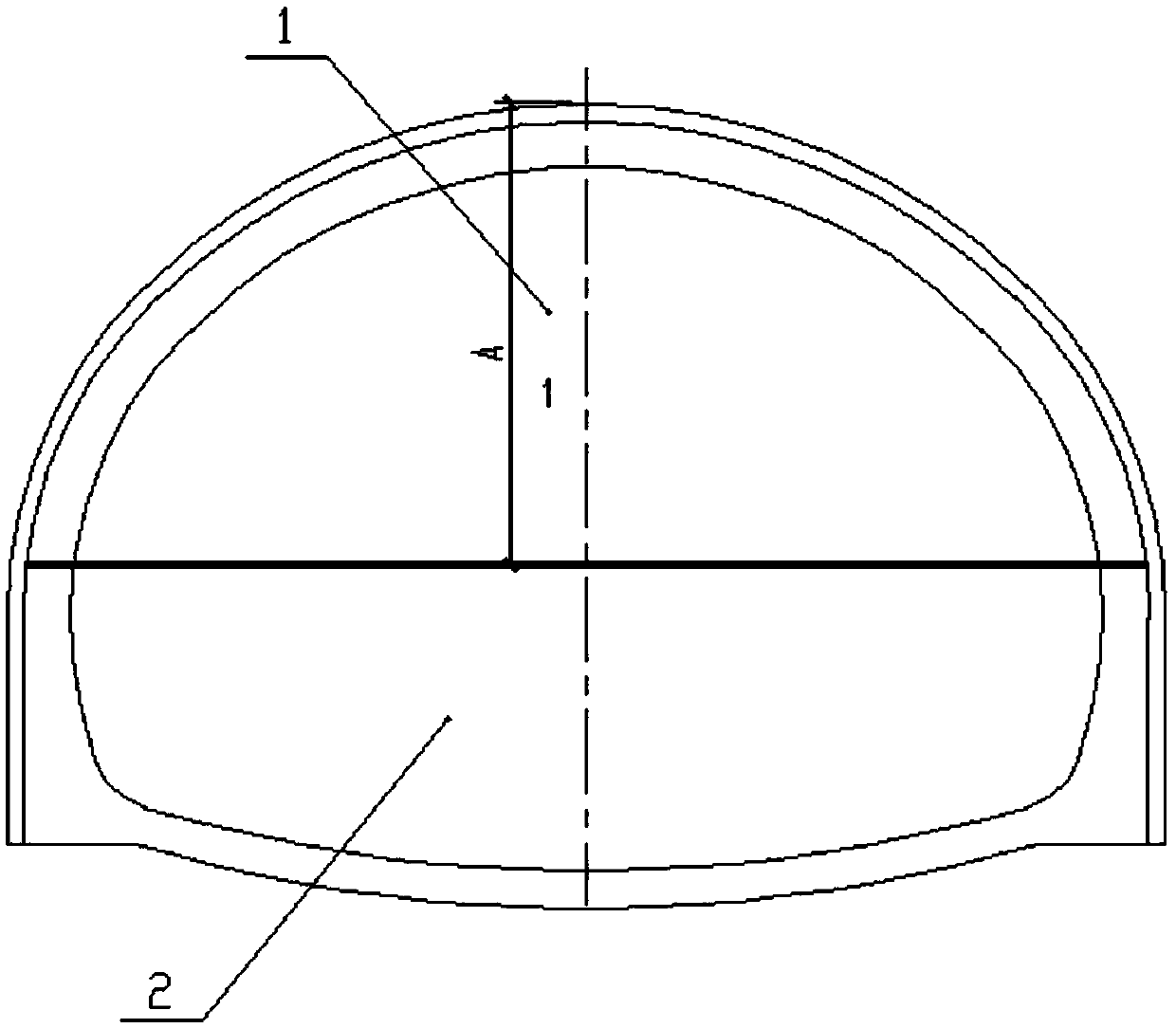

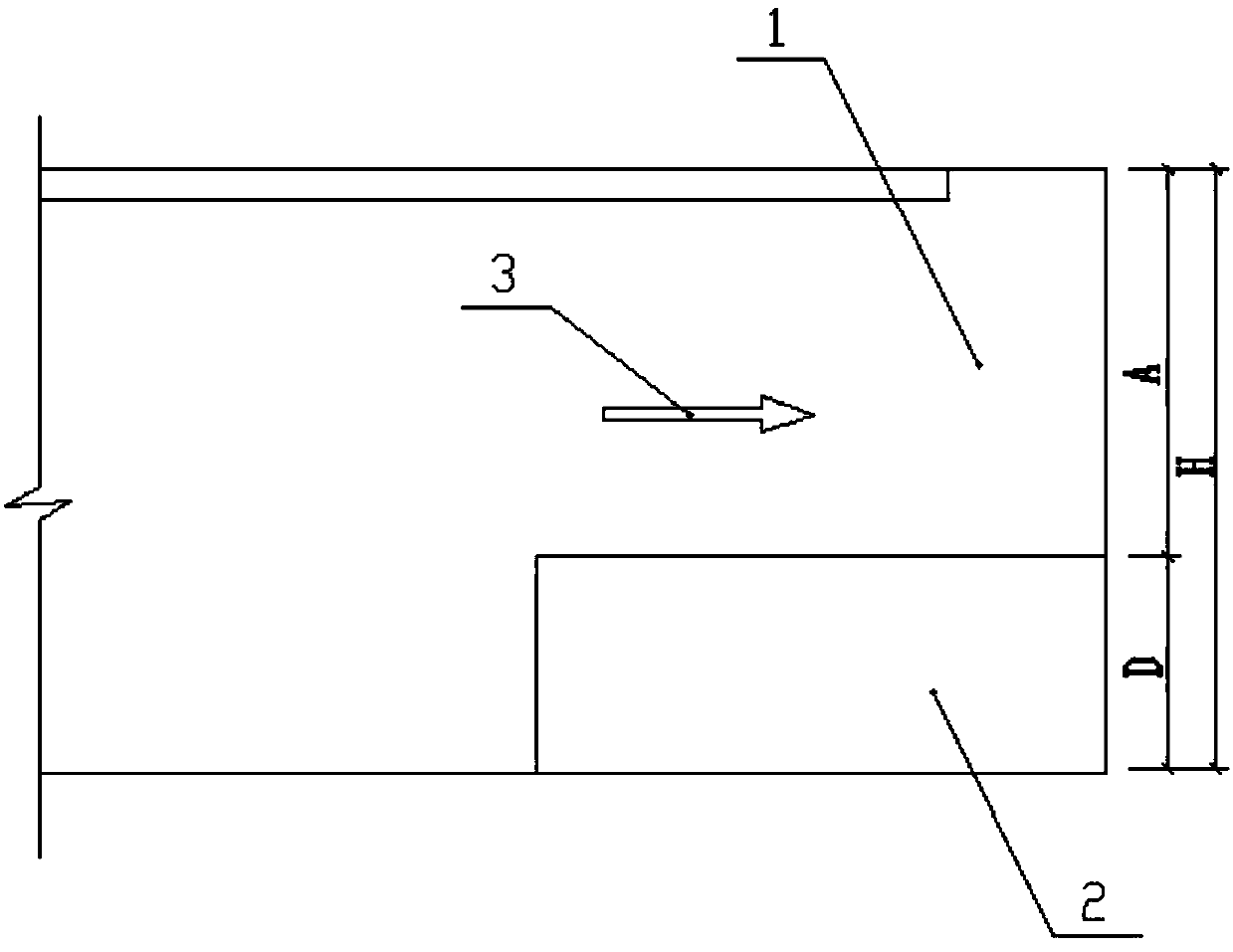

[0032] Such as figure 2 As shown in -3, in order to facilitate equipment placement, slag removal transportation, bench placement, and ensure sufficient operating space for primary support, the step height of long-span tunnels should be determined in combination with arch rise-span ratio and mechanical space required. The rise-span ratio of the arch is not less than 1 / 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com