Double-end bucket hook structure of large excavator

An excavator, large-scale technology, applied in the field of double-headed bucket hook structure of large excavators, can solve the problems of reducing the service life of the gear rod and tooth tip, working load, large impact load, and cost increase, etc., to achieve convenient excavation and transfer, The effect of increasing strength and accelerating loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

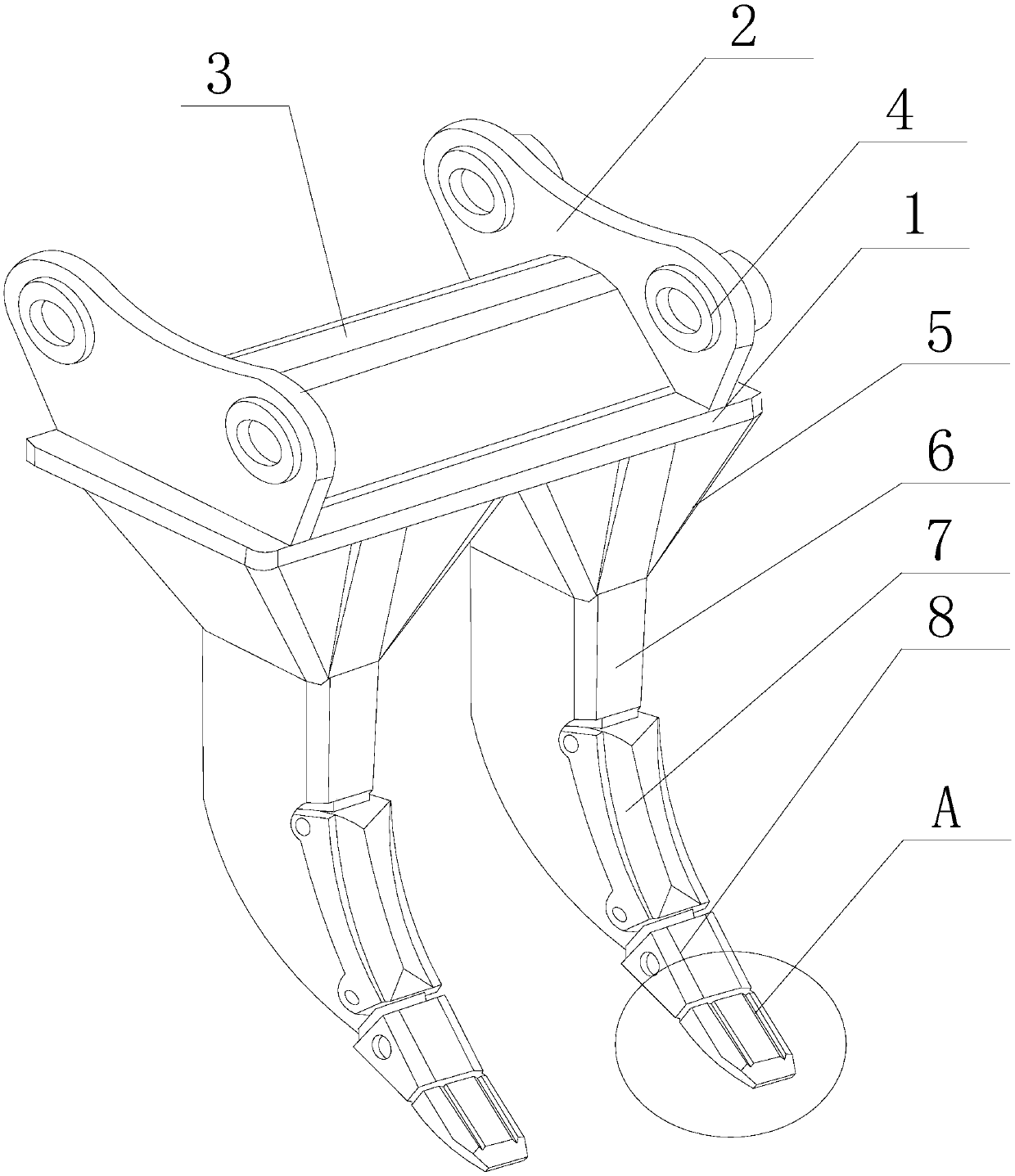

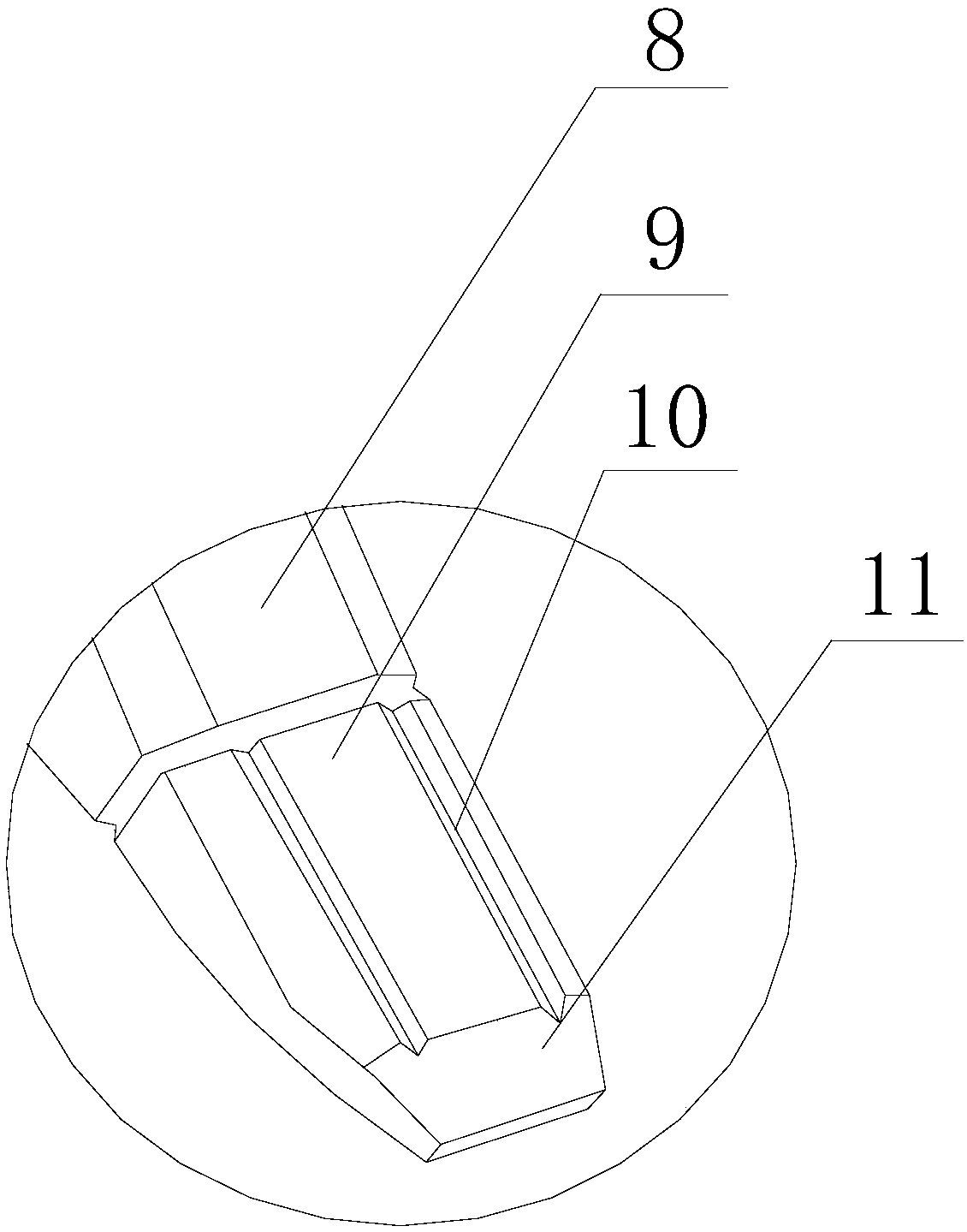

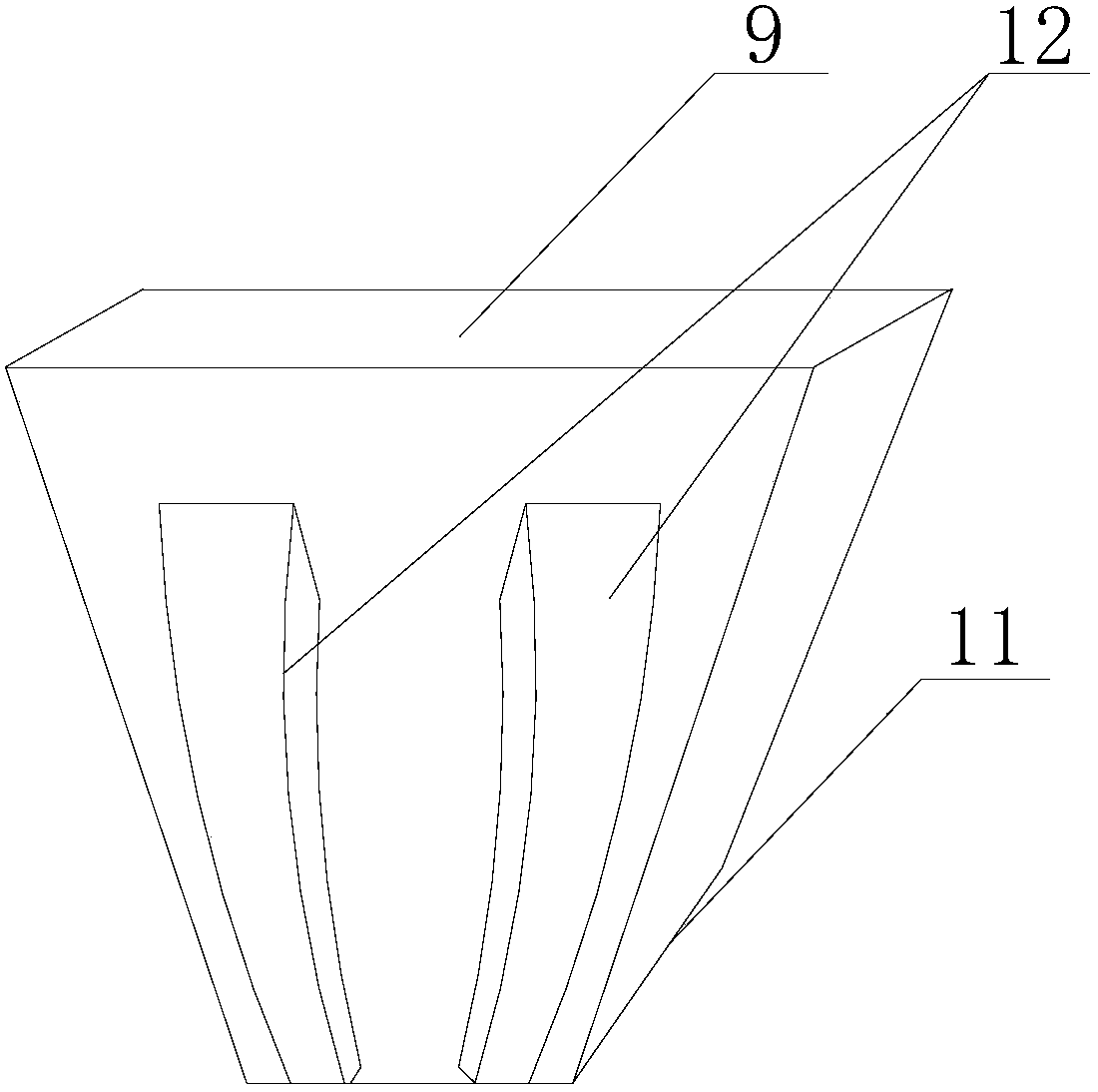

[0021] like Figure 1 ~ Figure 3 As shown, this embodiment includes a square connecting plate 1, ear plates 2 with shaft holes 4 are installed on both sides of the upper part of the connecting plate, and a trapezoidal reinforcing plate 3 is welded between the two ear plates 2, Weld two or more than two arc-shaped tooth bars 6 with bucket teeth 9 at the bottom middle position of the connecting plate 1, and connect with the outer wall of the tooth bar 6 at the square peripheral edge of the connecting plate 1 A reinforcing plate 5 is welded between them, and the distance between the upper ends of two adjacent gear rods 6 is 40-60 cm, and an alloy sheath 7 is installed on the inner side of the curved surface of the gear rod 6 through a pin shaft, A tooth sleeve 8 is installed on the upper part of the bucket tooth 9 through a pin shaft, and two arc-shaped diversion grooves 10 are opened on the inner side wall of the lower part of the bucket tooth 9, and the diversion groove 10 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com