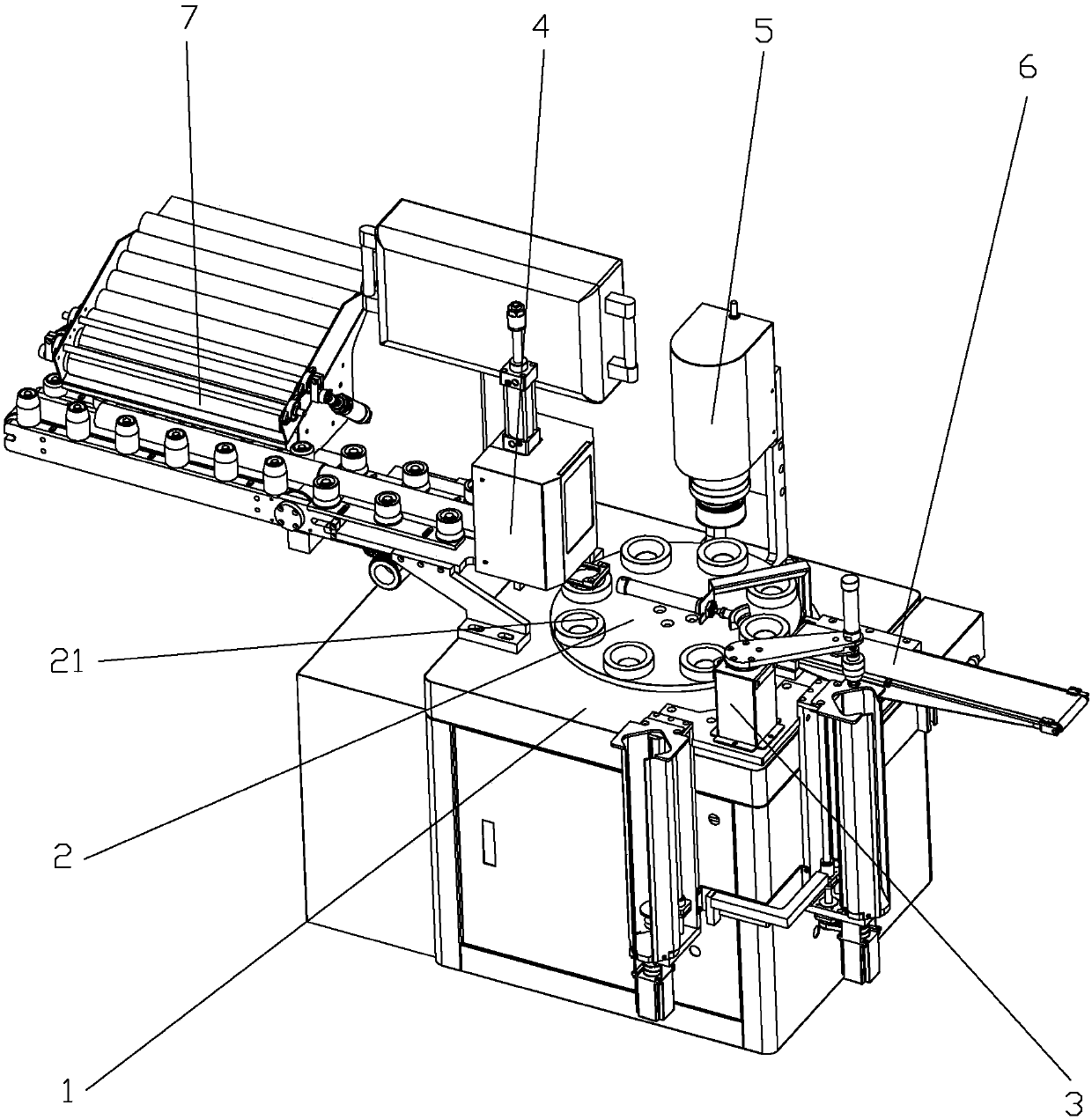

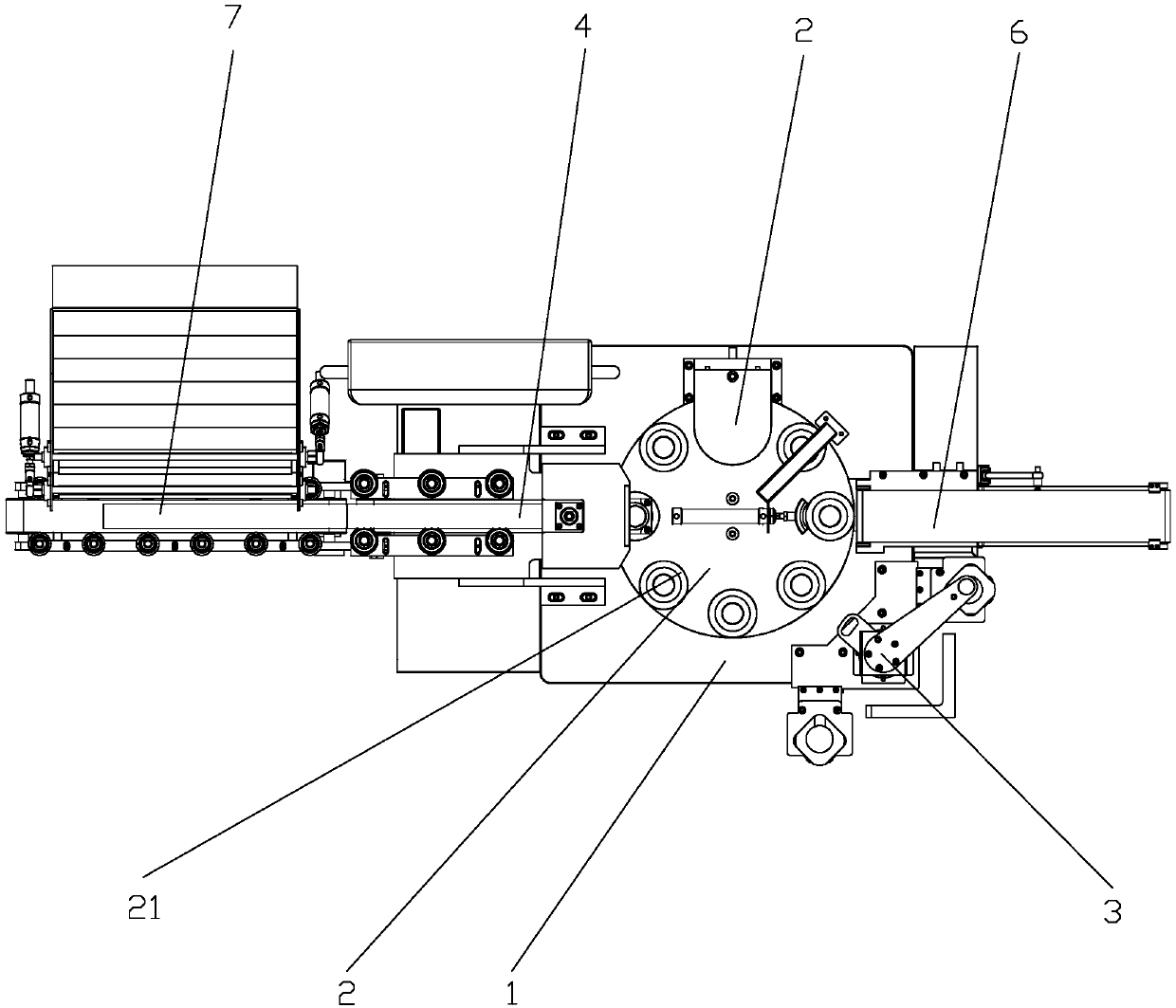

Double-station egg tart tin paper cup loading system

A double-station, tinfoil cup technology, applied in the direction of conveyors, rotary conveyors, conveyor objects, etc., can solve the problems of not being able to meet large-scale industrial production and low efficiency, and achieve labor cost savings, high efficiency, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] refer to Figure 1 to Figure 8, a double-station egg tart tinfoil cup feeding system, including a main frame 1, a turntable 2 is arranged on the main frame 1, a plurality of cup holders 21 uniformly distributed in the circumferential direction are arranged on the turntable 2, and the cup holders 21 is provided with a cavity 211 for placing tinfoil cups. The main frame 1 is connected with a power device for driving the turntable 2 to rotate. The power device is preferably composed of a motor and a reduction box. Of course, an oil motor, an air motor, etc. can also be used. , the power unit drives the turntable 2 to rotate at a fixed frequency, and each step rotates at a certain angle; the main frame 1 is connected with a tinfoil cup feeding device 3, a dough cutting device 4, and a forming device arranged in sequence around the turntable 2 5. The blanking device 6 forms a plurality of stations; the dough cutting device 4 includes a mounting frame 401 affixed to the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com