Automatic dumping type medical dustbin

A garbage bin and garbage technology, applied in the field of medical equipment, can solve the problems of easy contamination of medical garbage germs, reduce work efficiency, increase labor load, etc., achieve the effect of reducing the number of times of dumping garbage, reducing workload, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

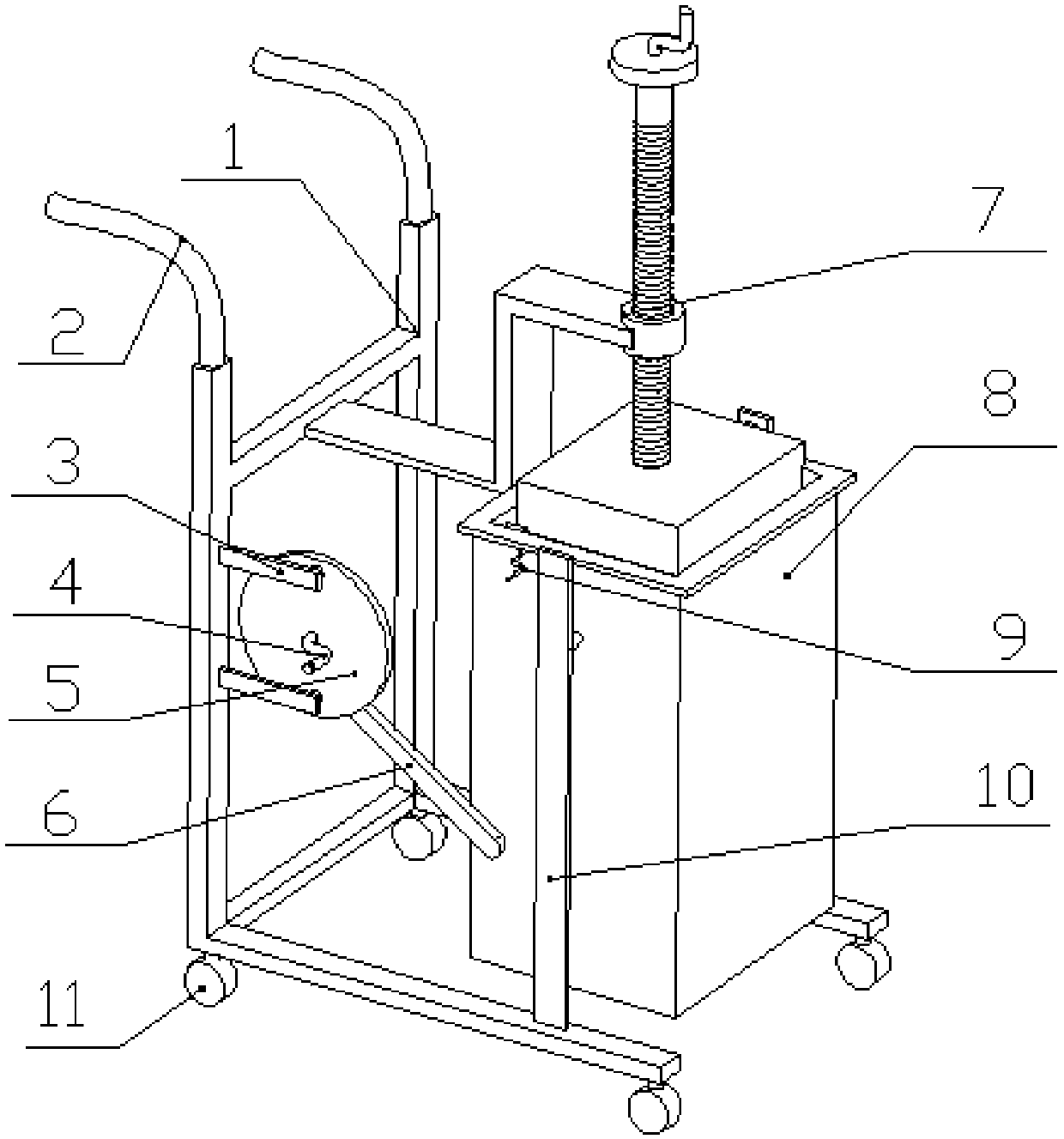

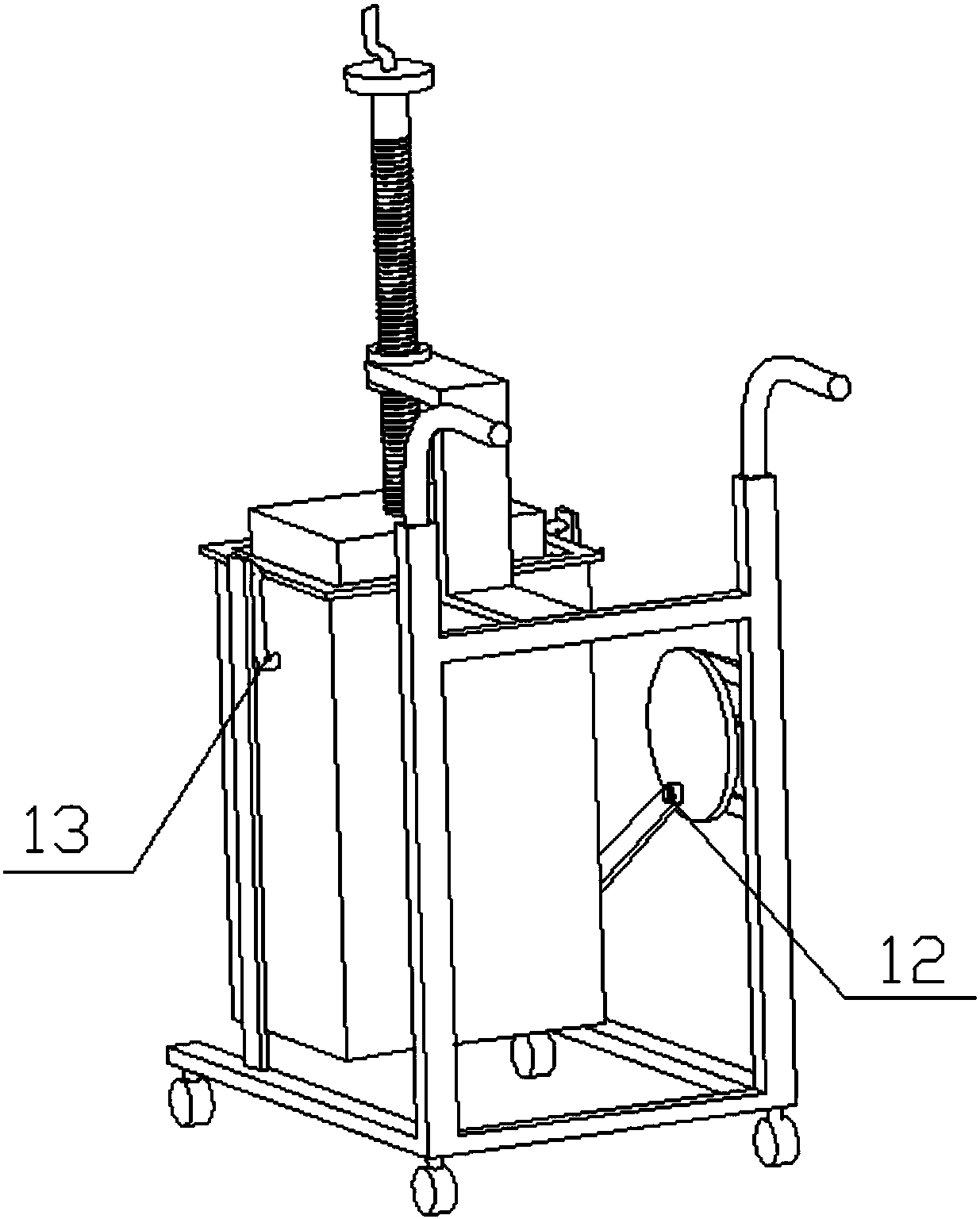

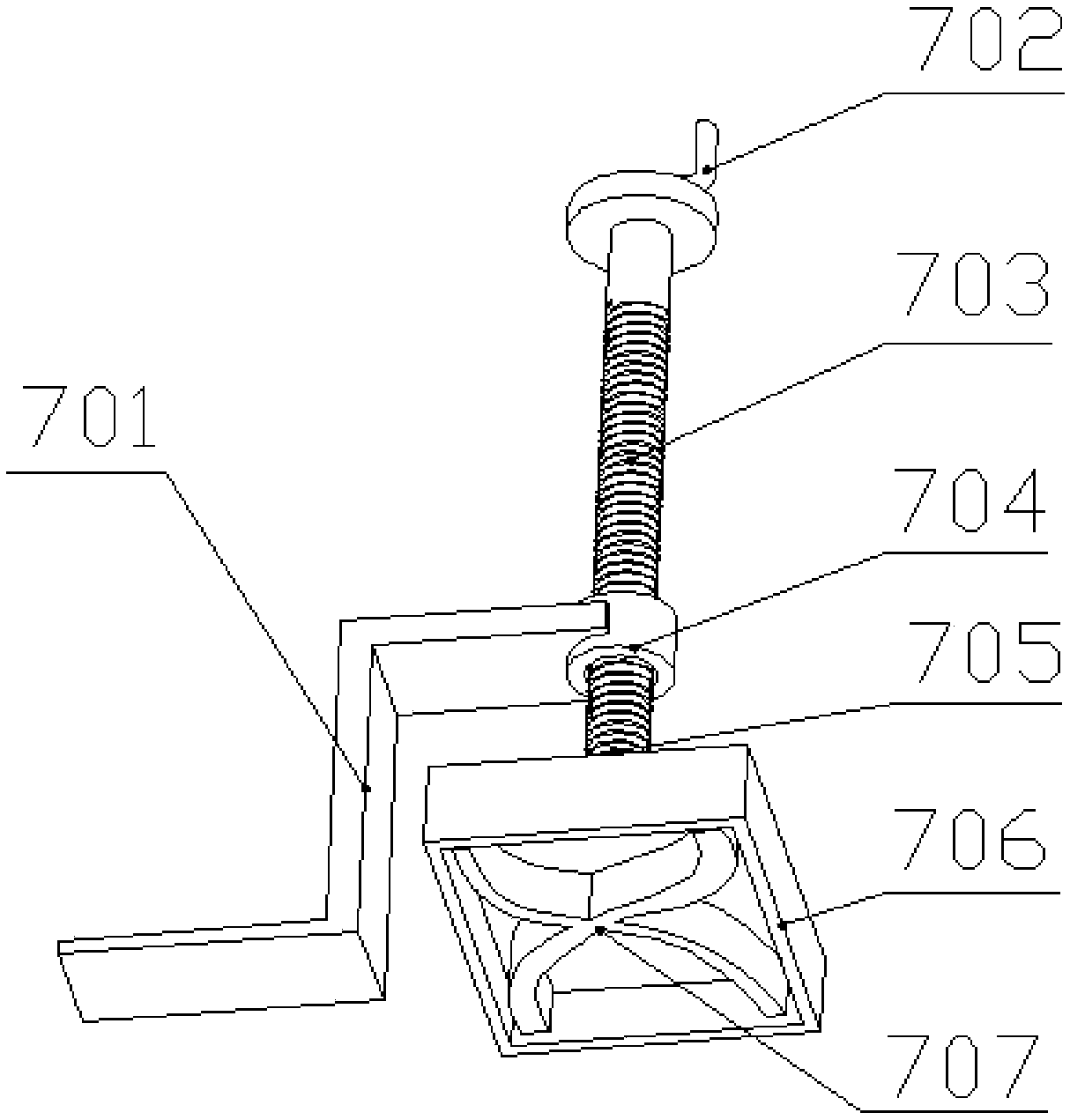

[0016] An automatic dumping medical waste bin is composed of a vehicle frame 1, an armrest handle 2, a crank fixing plate 3, a dumping handle 4, a crank plate 5, a connecting rod 6, a compression crushing mechanism 7, a dustbin 8, and a waste pushing mechanism 9. Composed of garbage bin fixing plate 10, wheels 11, crank boss 12, and rotating connecting pipe 13, it is characterized in that two handrail handles 2 are installed on the top of the frame 1, and garbage bins are fixedly installed on the front end of the frame 1. Box fixed plate 10, rubbish bin 8 are connected together with rubbish bin fixed plate 10 by rotating connecting pipe 13, can rotate freely around rotating connecting pipe 13, vehicle frame 1 rear end is fixedly installed with two crank fixed plates 3, crank disc 5 It is fixed on two crank fixing plates 3 and can rotate freely. A dump hand crank 4 is fixedly installed in front of the crank fixing plate 3, and a crank boss 12 is fixedly installed behind the cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com