Bracket used in machining

A technology for mechanical processing and workpieces, applied in the field of mechanical processing brackets, to achieve the effect of increasing the contact area, promoting the use value, and preventing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

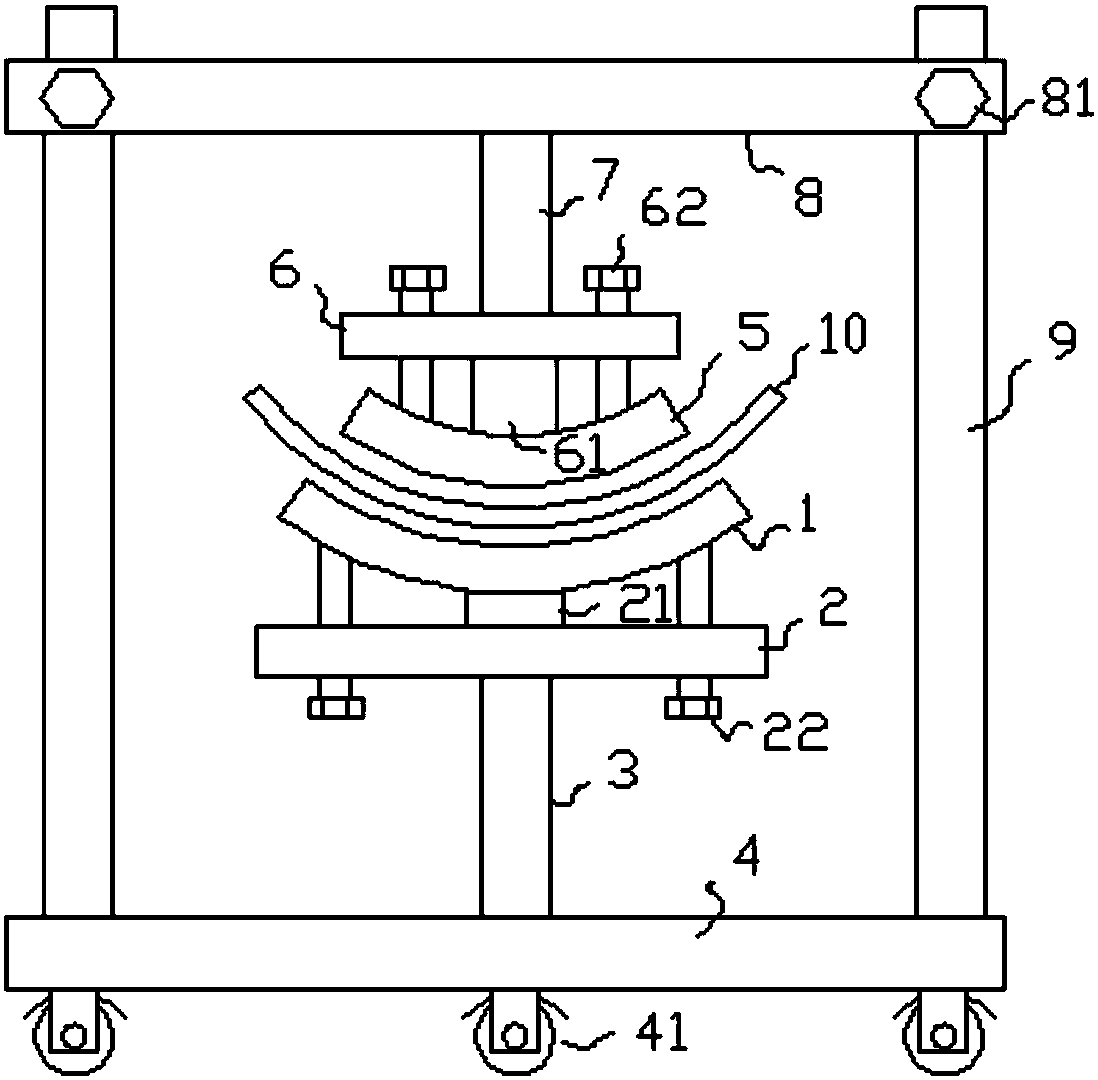

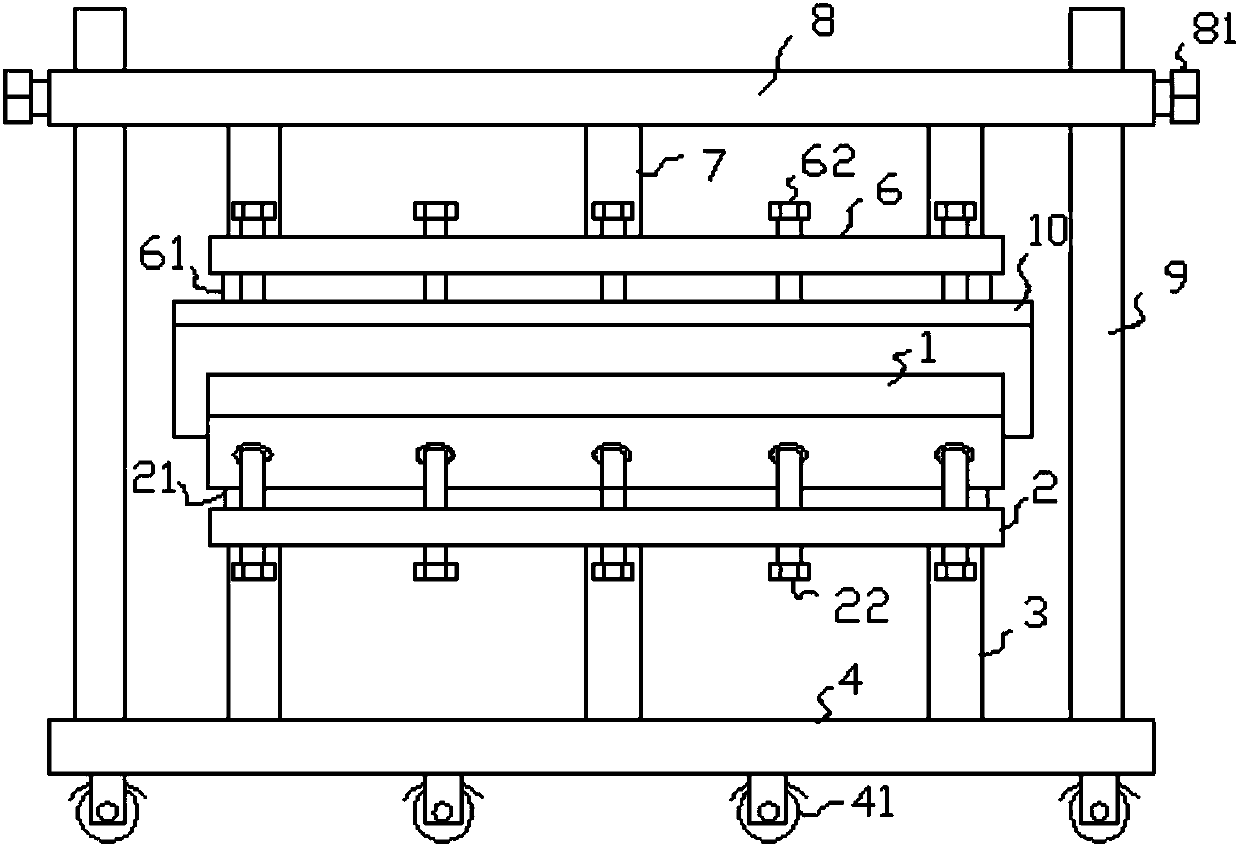

[0022] Such as figure 1 , figure 2 As shown, the bracket used for machining includes a lower arc-shaped rubber frame plate 1 matched with an arc-shaped workpiece 10, and the bottom of the lower arc-shaped rubber frame plate 1 is connected to the first flat plate through the first fixing block 21. 2. Fixed connection, the first flat plate 2 on both sides of the first fixed block 21 is screwed with the first fastening bolt 22 from bottom to top, the upper end of the first fastening bolt 22 is connected with the lower arc-shaped rubber frame plate 1 turn riveting. When in use, the lower arc-shaped rubber shelf plate can cooperate with the lower surface of the arc-shaped workpiece, and the arc of the lower arc-shaped rubber shelf plate can be adjusted through the first fastening bolt, which is beneficial to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com