Method for fire extinguishing of internal combustion locomotive through fine water mist

A technology for diesel locomotives and fine water mist, which is applied in fire rescue and other fields, can solve problems such as economic loss of diesel locomotives, delay in the best time to extinguish fires, and burnt locomotives. The effect of no damage to the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

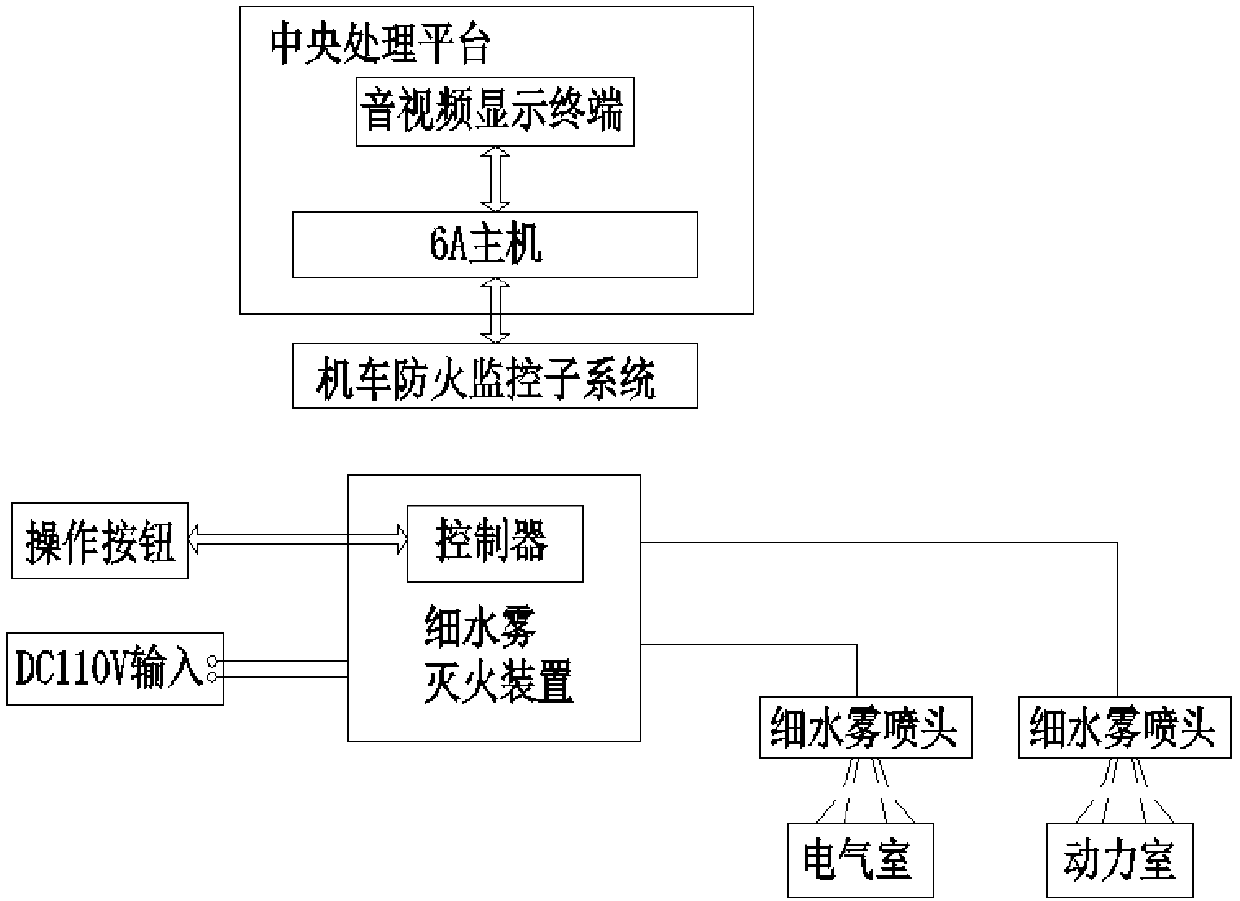

[0013] The fire extinguishing method of the present invention is mainly composed of the following three parts: an operation box 1 , a fine water mist fire extinguishing device 2 , and a pipe network 3 .

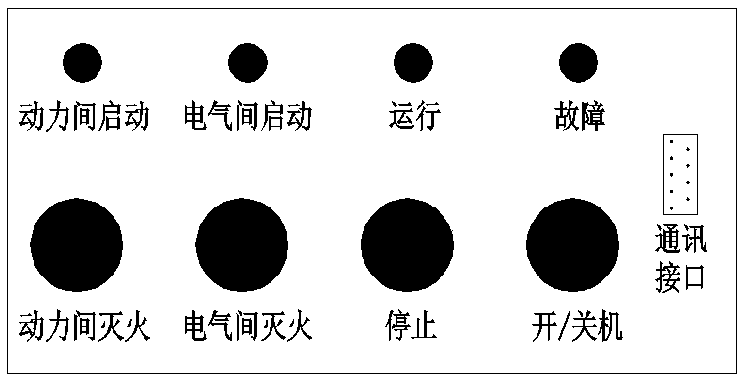

[0014] Such as figure 2 As shown, the operation box is equipped with four indicator lights, four buttons and a communication interface. The indicator lights are power room start, electrical room start, operation, fault; the buttons are power room fire extinguishing, electrical room fire extinguishing, stop, and on / off. The start indicator light of the power room and the start indicator light of the electrical room are always off when there is no spraying action; when the "spray" button is pressed for three seconds or more, it will flash in seconds, indicating that the "spray" button is released, and the "spray" button is always on. Lights up to indicate that spraying is on. When the fire extinguishing device is in normal operation, the operation indicator flashes in second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com