Micro gyroscope adaptive high-order super-twist slip form control method

A technology of micro-gyroscope and control method, applied in adaptive control, general control system, control/regulation system and other directions, can solve the problems of reduced sensitivity and accuracy of gyroscope system, inability to accurately implement control law, inability to accurately obtain and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0076] 1. Mathematical model of micro gyroscope:

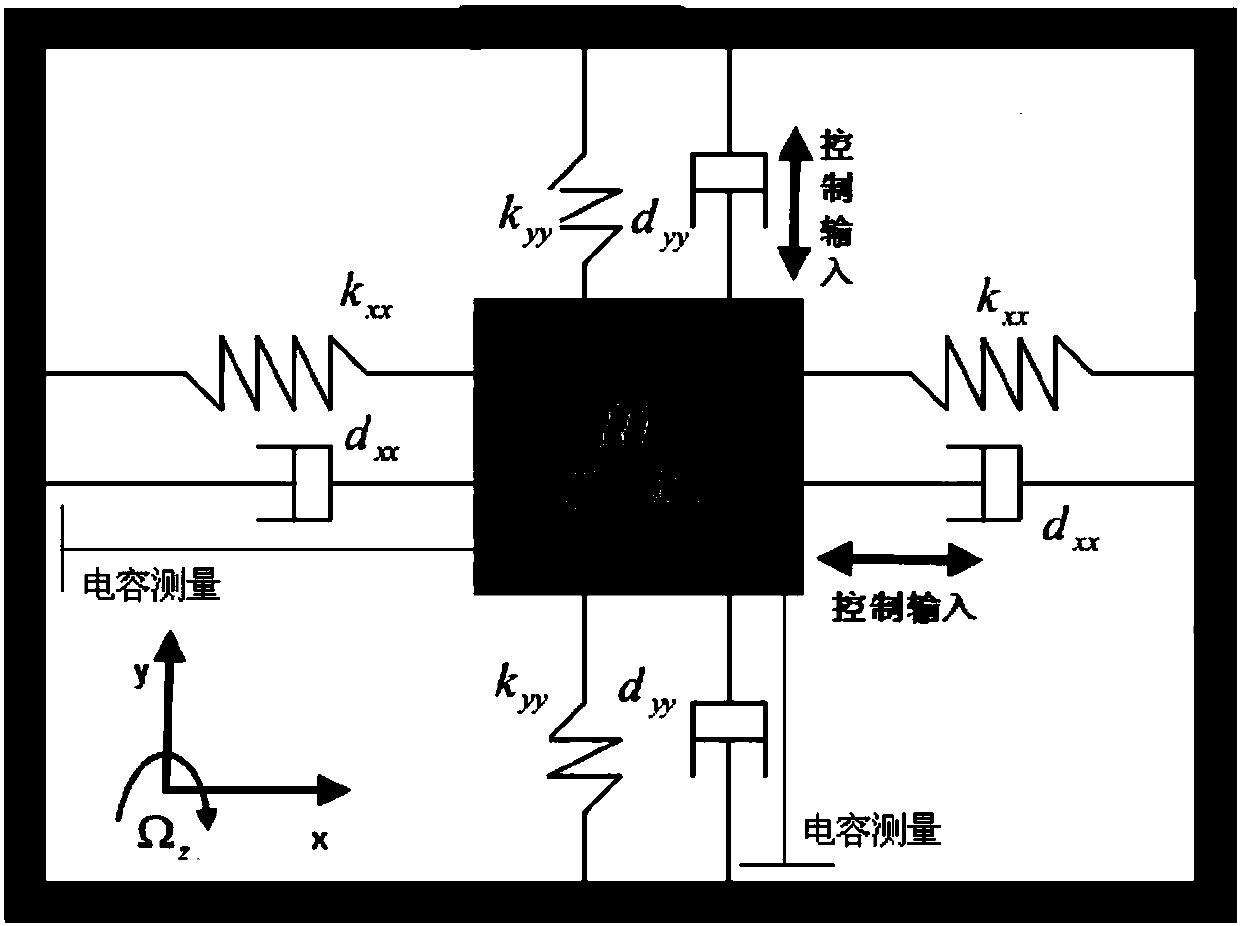

[0077] A micro-vibration gyroscope usually consists of three parts: a mass suspended by an elastic material support, an electrostatic drive device, and a sensing device. This can be simplified as figure 1 A damped oscillatory system consisting of a mass and a spring is shown, which shows a simplified z-axis micromechanical vibratory gyroscope model in Cartesian coordinates.

[0078] According to Newton's law in the rotating system, comprehensively considering the influence of various manufacturing errors on the micro-gyroscope, and then through the dimensionless processing of the micro-gyroscope, the mathematical model of the micro-gyroscope is finally obtained as follows:

[0079]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com