Three-dimensional adjustable wall-adhering mounting mechanism

An installation mechanism and wall sticking technology, applied in mechanical equipment, supporting machines, etc., can solve the problems of display screen splicing gap, limited installation space construction accuracy, installation mechanism accuracy difficult to meet ultra-high density display screen, etc., to solve the problem of joints problems, improve the display effect, and save the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

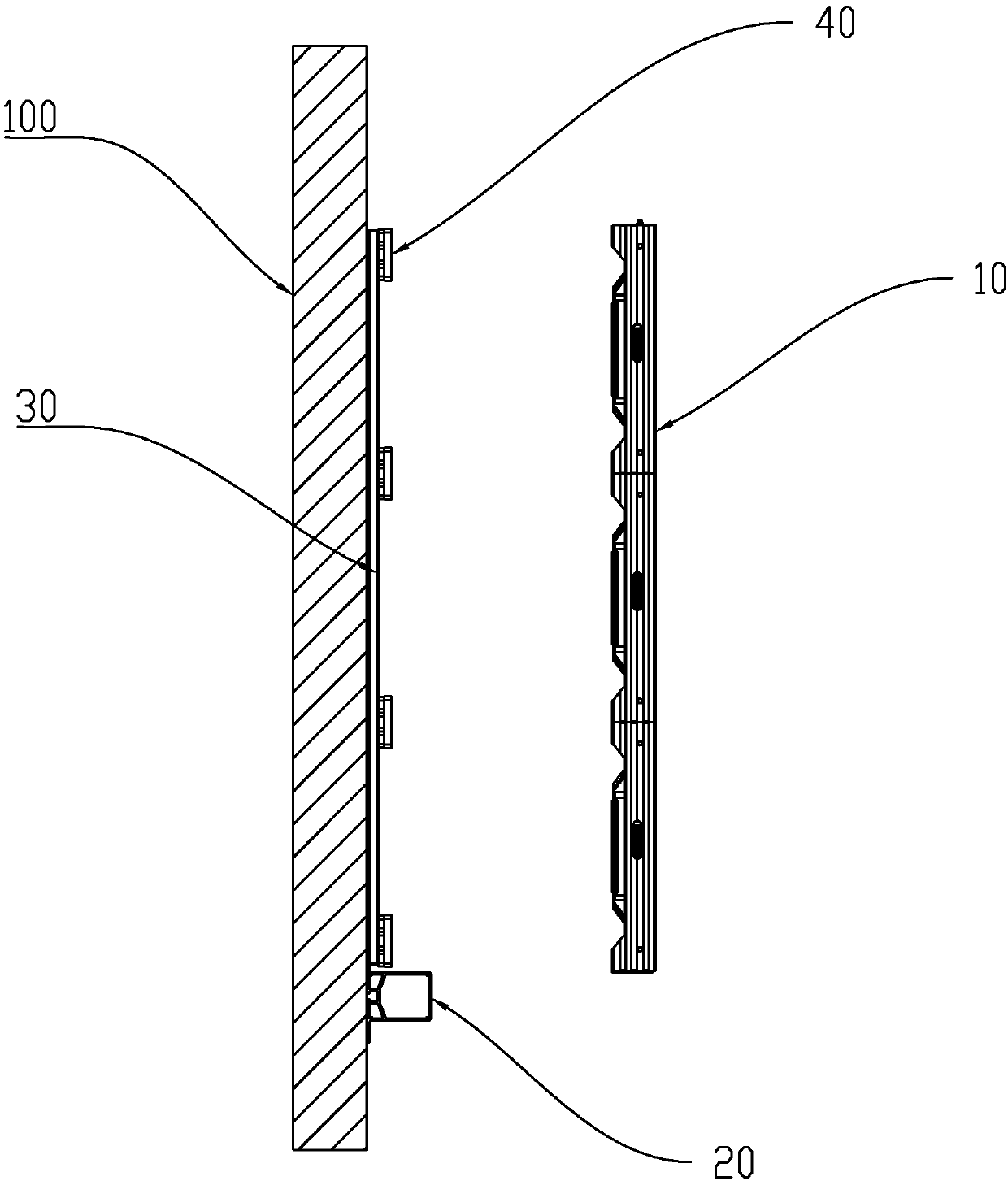

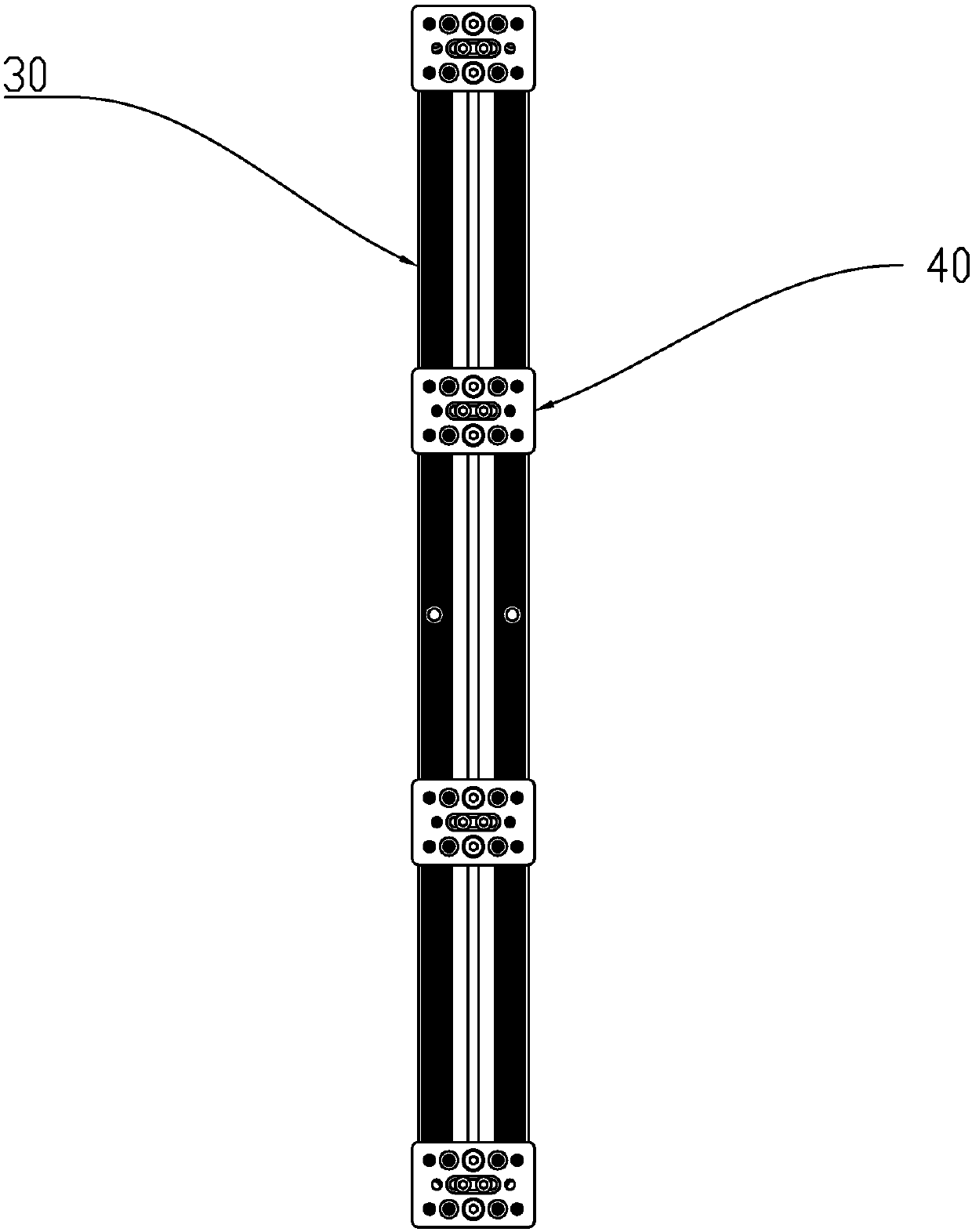

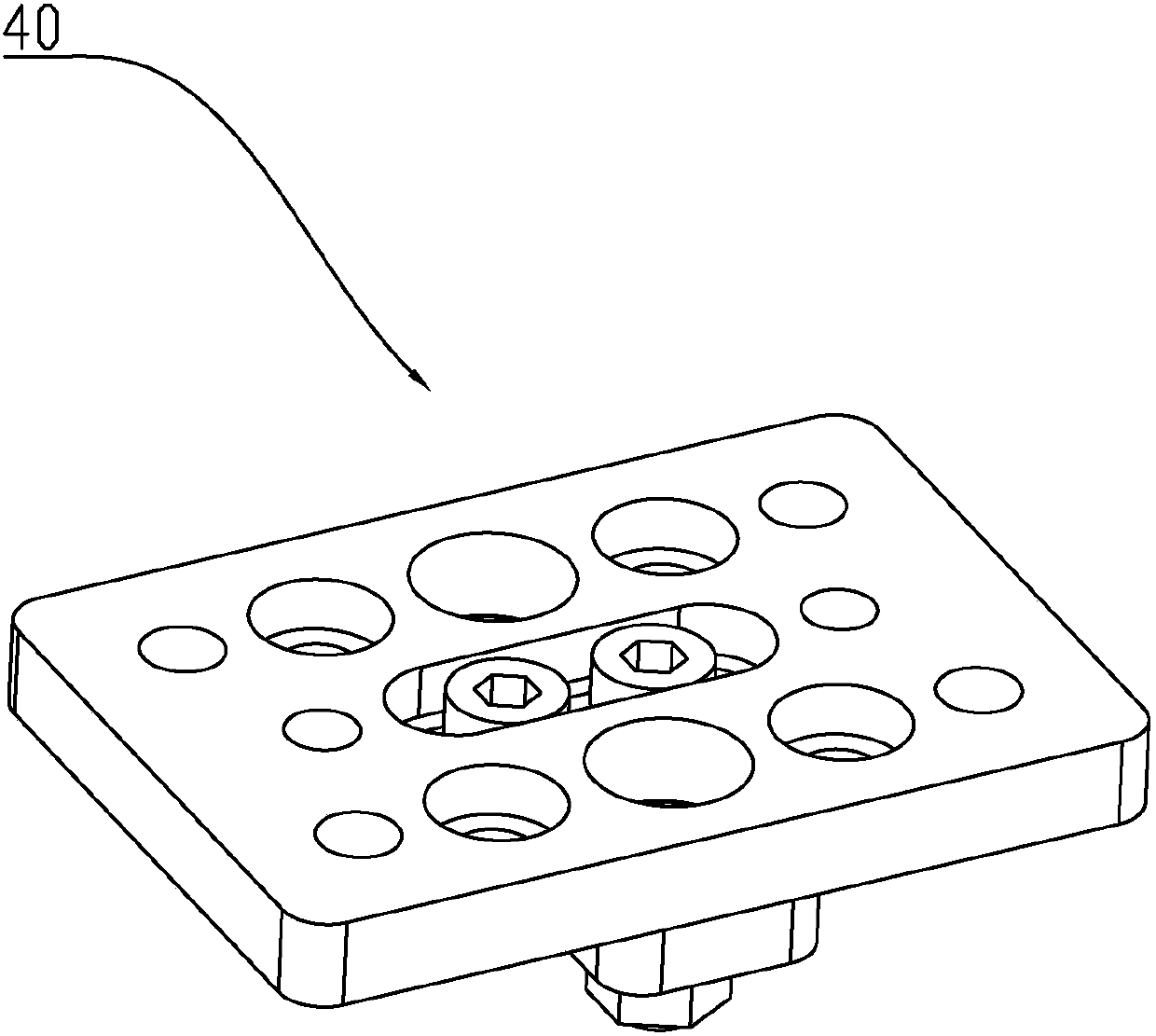

[0038] like Figure 1 to Figure 11 In the specific embodiment shown, the present invention discloses a three-dimensional adjustable wall-mounting installation mechanism, which includes a support seat 20 fixedly connected to the wall body 100 and used to support the display screen 10 , and a number of rods arranged above the support seat 20 Slide rail 30, slide rail 30 is fixedly connected with body of wall 100, and slide rail 30 is provided with chute 31, and slide rail 30 is connected with several coupling assemblies 40 through chute 31; to adjust the position of the display screen 10.

[0039] Wherein, in this embodiment, both the slide rail 30 and the support base 20 are profiles.

[0040] Specifically, as Figure 1 to Figure 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com