Corner fabricated wall

A prefabricated and corner technology, applied to walls, building components, buildings, etc., can solve problems such as field destruction, achieve the effects of ensuring strength, shortening the completion period, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

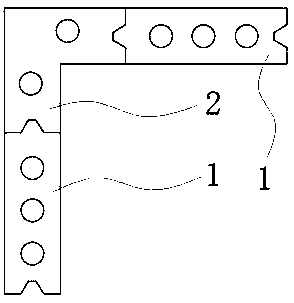

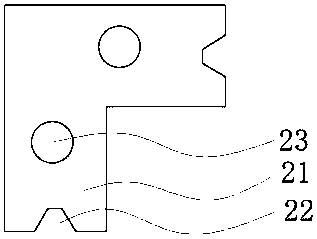

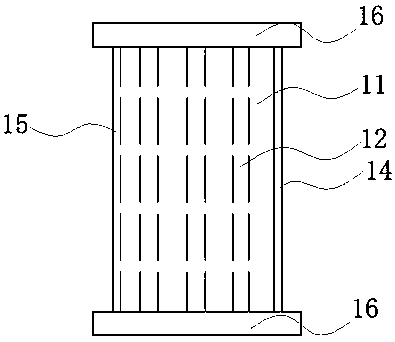

[0028] A corner assembled wall, such as Figure 1 to Figure 4 As shown, it includes a wall panel 1 and a corner assembly column 2 for assembling the wall panel at the corner. The wall panel 1 includes a brick body 11, and the brick body 11 is provided with one or two rows of through holes 12. The brick body 11 The assembly surfaces on both sides are respectively provided with an assembly mechanism for brick installation. The assembly mechanism includes a strip-shaped convex portion 14 arranged on one side, and a first strip-shaped concave portion 15 matching the strip-shaped convex portion is provided on the other side. , the brick body 11 is also provided with reinforcing nets 13 for strengthening the strength of the brick body, and the reinforcing net 13 is arranged in the brick body, and the corner assembly column 2 includes a column body 21 and is arranged on the column body for assembling wall panels The second strip-shaped recess 22 is provided in the cylinder 21, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com