Ring spinning machine with vertically movable spindle rail

A ring spinning machine, vertical movement technology, applied in the direction of continuous winding spinning machines, spinning machines, textiles and papermaking, etc., can solve the threat to the reliability of the ring spinning machine operation, and the lifting of the spindle track out of control and other problems, to achieve the effect of reliable locking and unlocking and operation reliability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

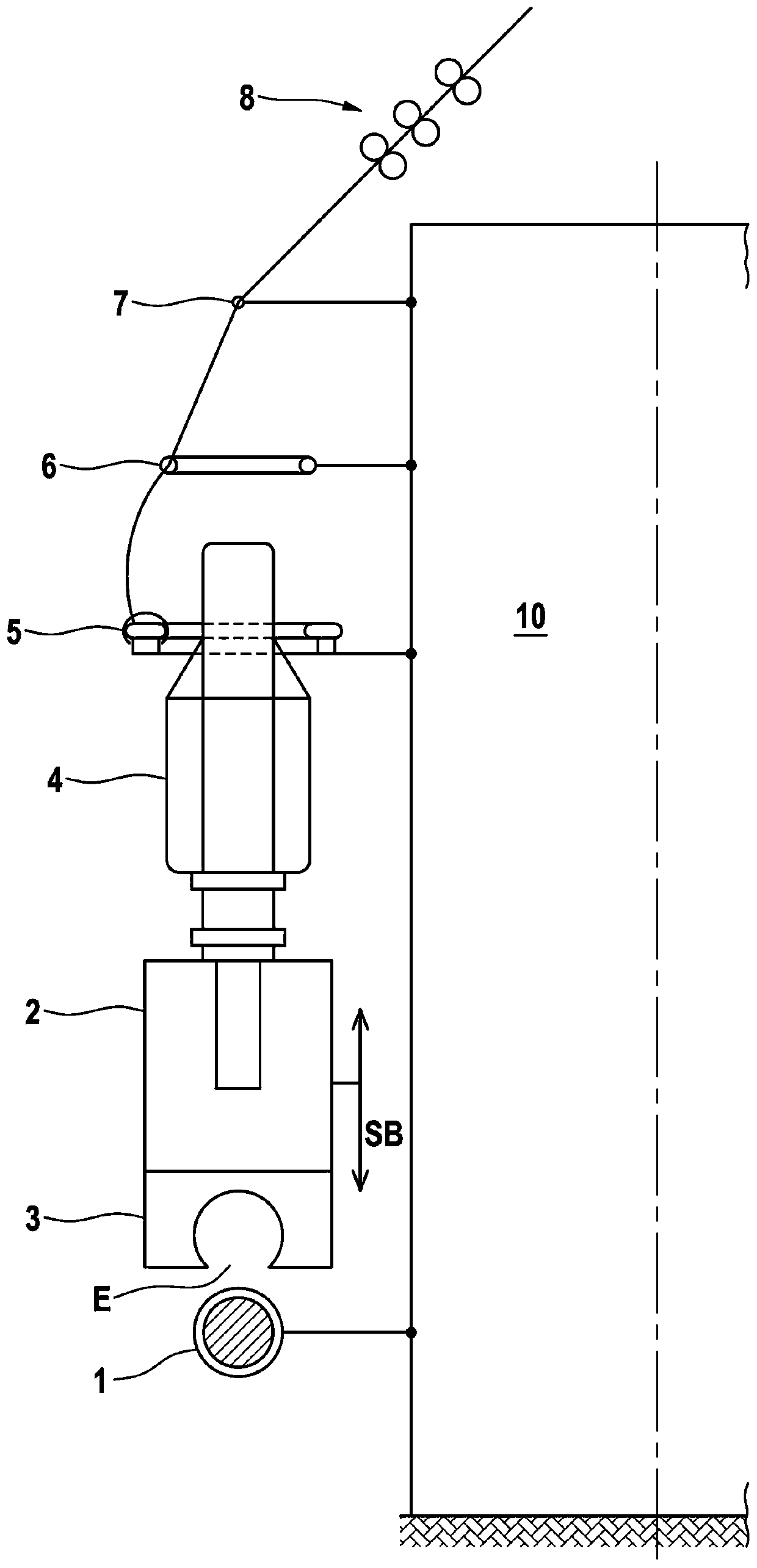

[0016] exist figure 1 An example of a ring spinning machine 10 with a vertically movable spindle rail 2 is shown. From top to bottom, a drafting device 8 , a thread guide 7 , a balloon ring 6 and a spinning ring 5 and an axially displaceable positioning rod 1 as a joint for the locking device are provided, for example, fixed to the machine. .

[0017] The spindle rail 2 together with the yarn body 4 and the baffle 3 arranged below the spindle rail 2 can be moved back and forth vertically on the ring spinning machine 10 according to the double arrow SB by means not shown.

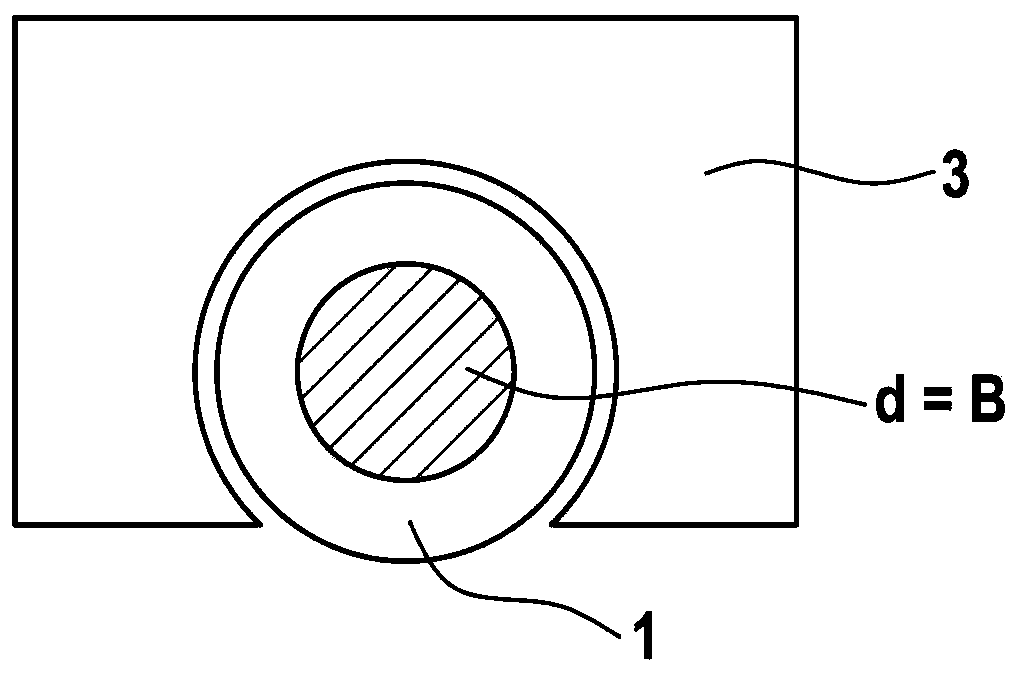

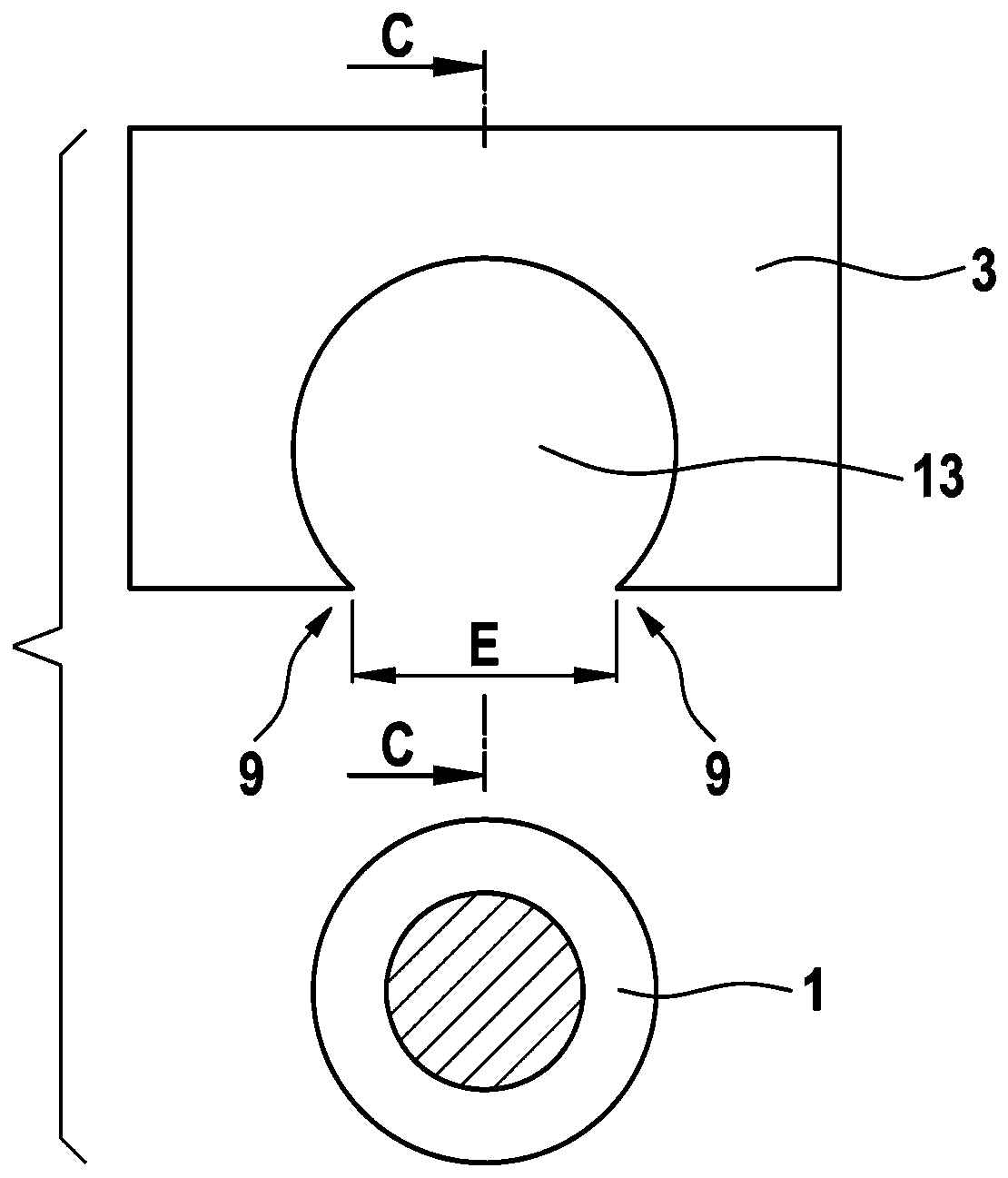

[0018] Along the ring spinning machine 10, a positioning rod 1 having a diameter A is turned with a width C to a diameter B to form pockets 11 at a spacing corresponding to a number of spindle intervals. In the state shown, as figure 1 As shown, the ingot rail 2 is connected with the baffle 3, and its thickness D ( Figure 2c ) is significantly smaller than the width C ( image 3 ).

[0019] The baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com