A kind of Lactobacillus plantarum freeze-dried powder for prolonging the shelf life of yogurt and preparation method

A technology of Lactobacillus plantarum and freeze-dried powder is applied in the field of food microorganism application and food manufacturing, which can solve the problems of inability to prolong the shelf life of yogurt, and achieve the effect of prolonging the shelf life and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The cryopreserved L.plantarum LP90 was inoculated into fresh MRS liquid medium, cultured at 37°C for 16 hours, and subcultured twice to obtain activated L.plantarum LP90 strains.

[0027] The preparation method of MRS liquid medium is: 10g peptone, 10g beef extract, 5g yeast extract powder, 20g sucrose, 2g dipotassium hydrogen phosphate, 5g sodium acetate, 2g trisodium citrate, 1g Tween 80, 200mg magnesium sulfate, 54mg Mix manganese sulfate with 1000mL distilled water evenly, adjust the pH to 6.5, and then sterilize at 121°C for 15min.

[0028] Prepare a secondary liquid seed medium, inoculate the previously obtained activated L. plantarum LP90 strain into the medium according to the weight ratio of 2%, and cultivate at a temperature of 37° C. for 12 hours until the OD of the seed solution reaches 3.0.

[0029] The secondary seed liquid is transferred to the fermenter according to the weight ratio of 2%, and cultivated at 37°C for 10 hours. During the fermentation proc...

Embodiment 2

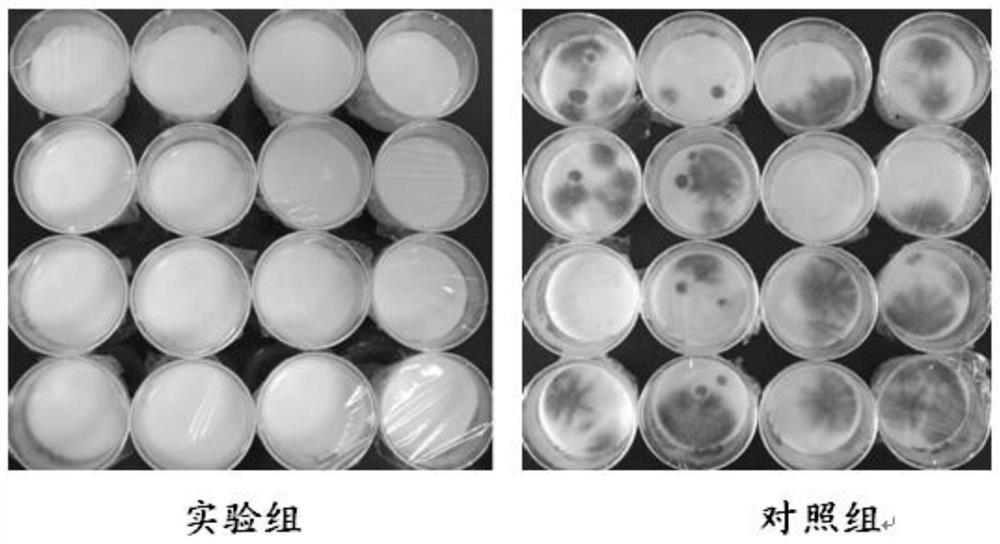

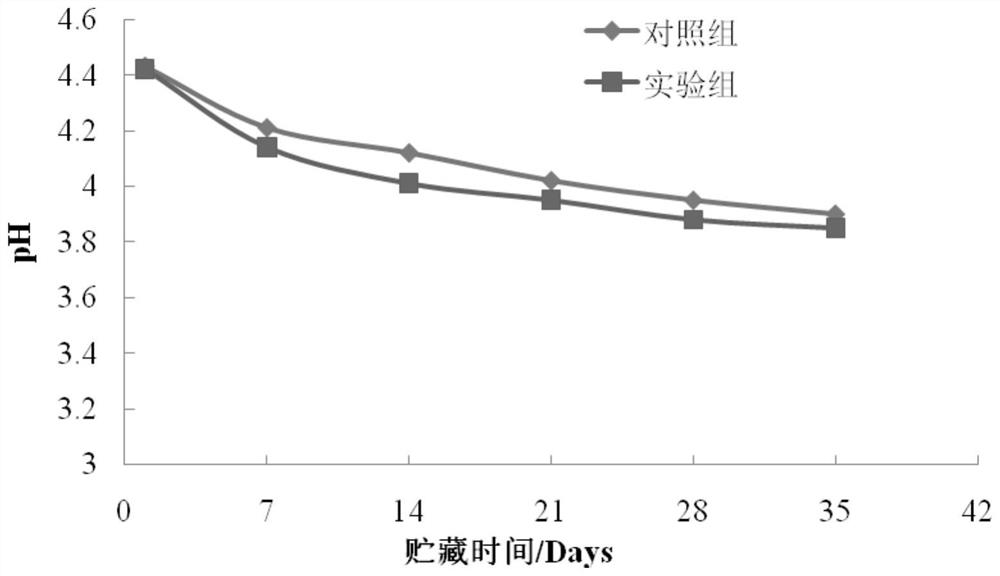

[0032] The effect of L.plantarum LP90 on prolonging the shelf life of yogurt was tested through the following accelerated experiments:

[0033] Prepare reconstituted milk with 11.6% of whole milk powder (or skim milk powder), 6% of sucrose, and 82.4% of water. After dissolving, sterilize at 95°C for 5 minutes, cool to 43°C and add starter, in order to make the results of the antibacterial experiment more obvious. , add yeast and mold liquid to the above reconstituted milk according to the final concentration of 10cfu / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com