A kind of high-efficiency production process of furan resin

A production process and furan resin technology are applied in the field of high-efficiency furan resin production processes, can solve problems such as low production efficiency and uneven mixing, and achieve the effects of improving impact range and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

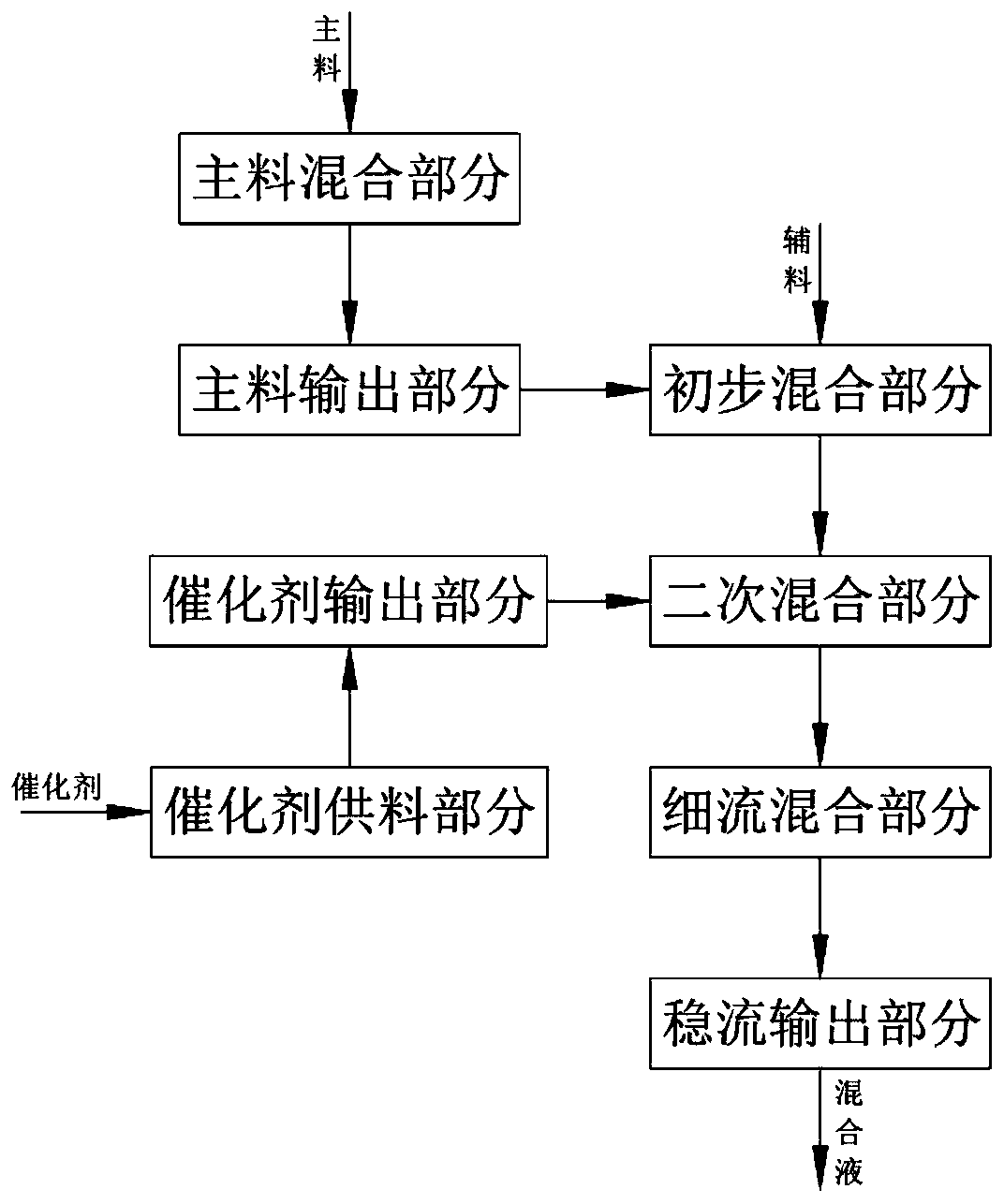

[0038] Refer to the attached figure 1 A high-efficiency production process of furan resin in Example 1 of the present invention is described.

[0039] A kind of high-efficiency production technique of furan resin, comprises the following steps:

[0040] (a) the main material output part, the main material is sprayed out through the spray hole 3113 through the main material bin with the rotating centrifugal force while being transported in a rotating manner through the mixing part 311 on the main material output assembly 31;

[...

Embodiment 2

[0049] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that : the jet hole 3113 is set in a spiral structure, the main material is sprayed out through the jet hole 3113 to form a main material layer spaced up and down, and the auxiliary material after diverging and splashing through the groove 3251 is between the main material layers.

[0050] Further, the step (c) includes the catalyst output part, the spray flow assembly 41 is connected with the main bin 312 in a synchronous rotation manner, and the roller 417 arranged on the mixing chamber 1 and the top protrusion at the bottom of the spray flow assembly 41 The table 416 is driven in a guiding transmission mode to realize the upward movement of the storage part 411 i...

Embodiment 3

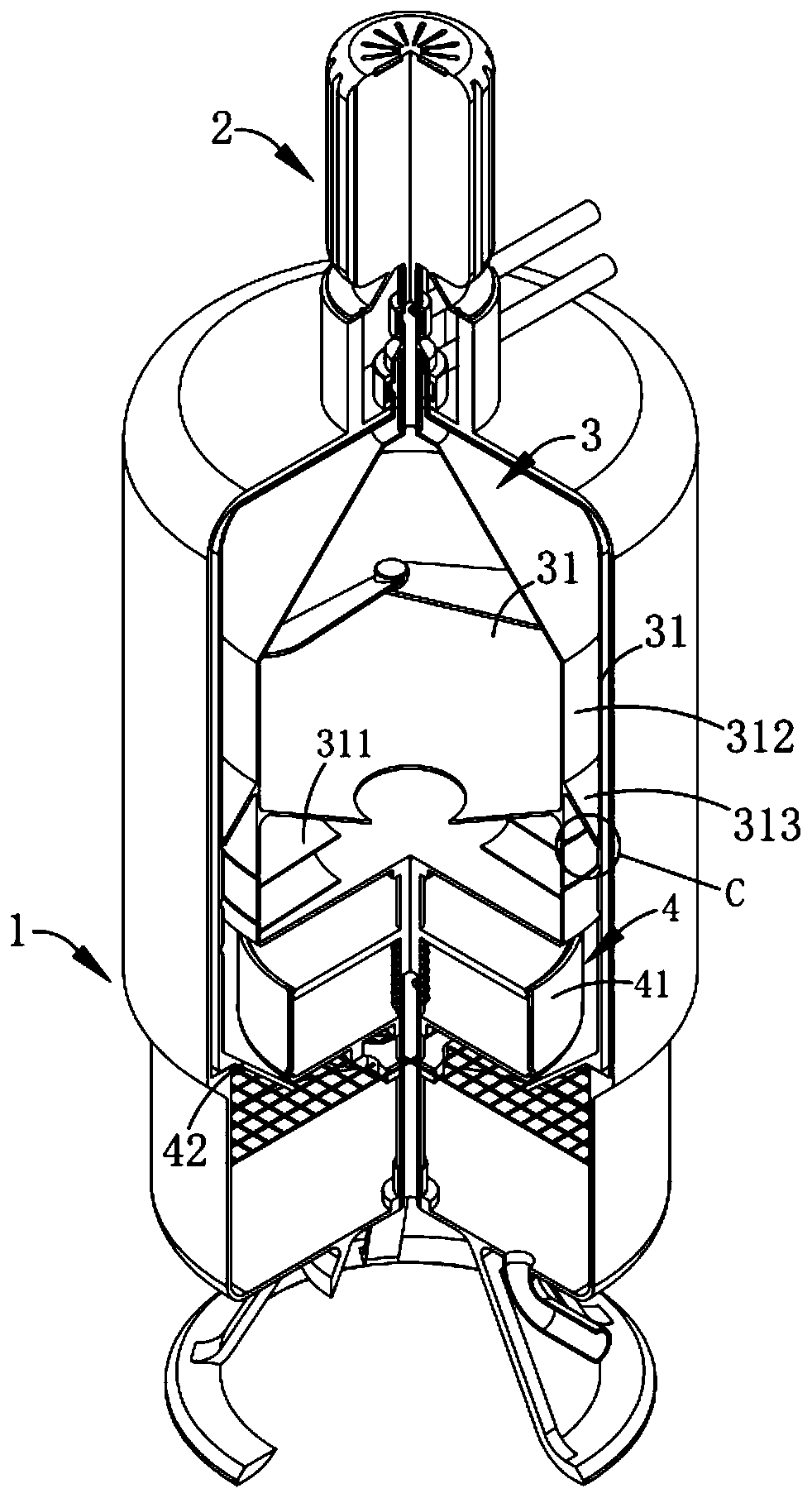

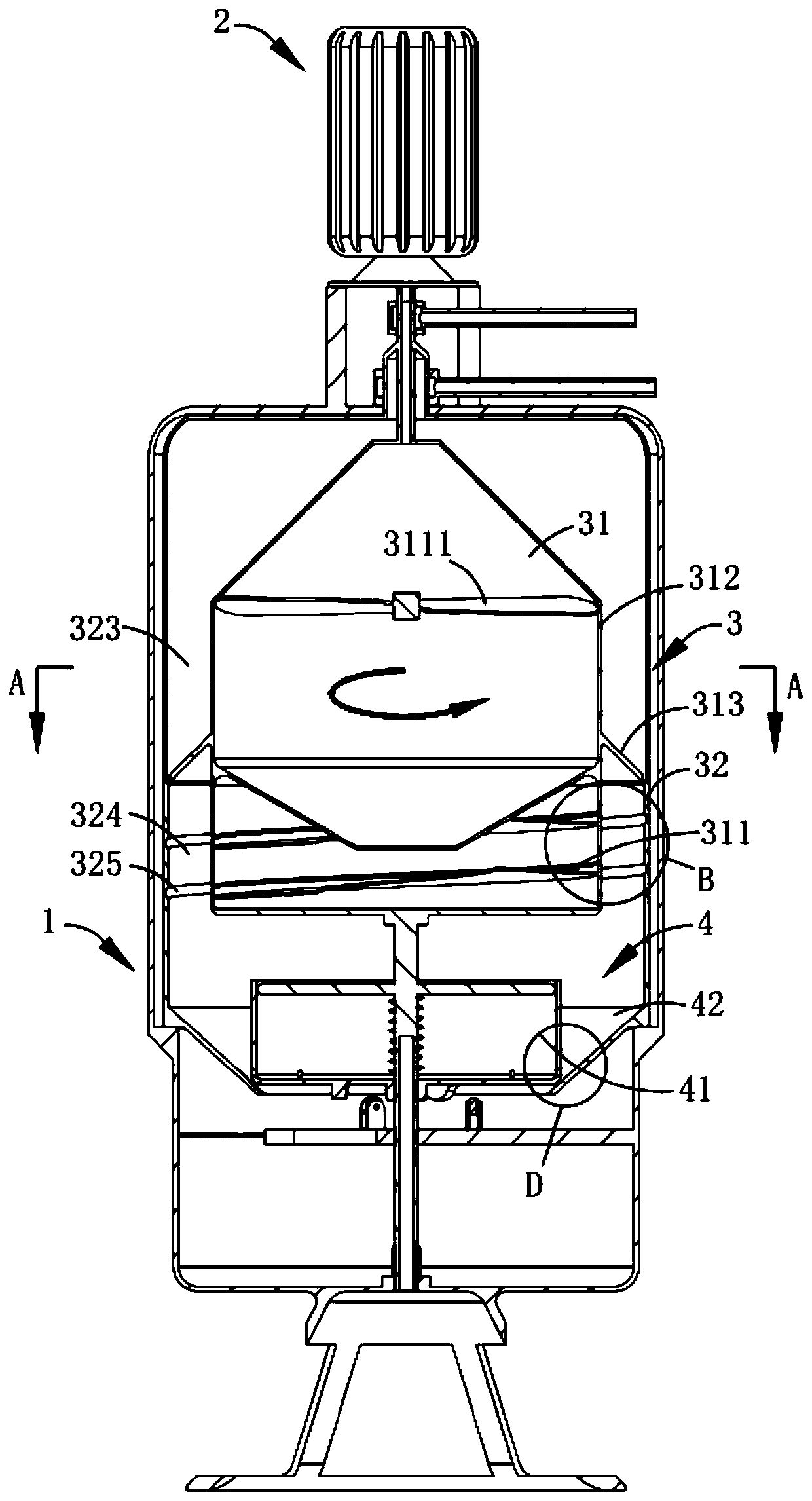

[0058] Reference attached Figure 2-10 A spiral multi-component mixing production device in Example 3 of the present invention is described.

[0059] like figure 2 , 3 , 4, 5, 6, 7 and 8, a spiral multi-component mixing production device includes a mixing chamber 1 and a driving mechanism 2, and also includes:

[0060] Preliminary mixing mechanism 3, described preliminary mixing mechanism 3 is arranged in the described mixing chamber 1, and it comprises main material output assembly 31 and auxiliary material mixing assembly 32, and the main material in main material output assembly 31 is mixed by being arranged on it After the output is driven by the part 311, it is ejected in a spiral structure; the auxiliary material in the auxiliary material mixing assembly 32 flows continuously through the flow port 321 arranged on it, and forms a liquid flow layer 322 below it; in this embodiment, the flow layer 322 The mouth 321 is provided with an annular mouth continuously, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com