A composite magnetic field type magnetorheological polishing head

A technology of magnetorheological polishing and compound magnetic field, which is applied in the field of polishing head, can solve the problems that it is difficult to accurately adjust the magnetic field strength in the polishing area, the electromagnet is easy to affect the polishing effect, and the electromagnet occupies a large space, so as to make up for the poor controllability of the magnetic field , Reduce the heat generation, the effect of less coil turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

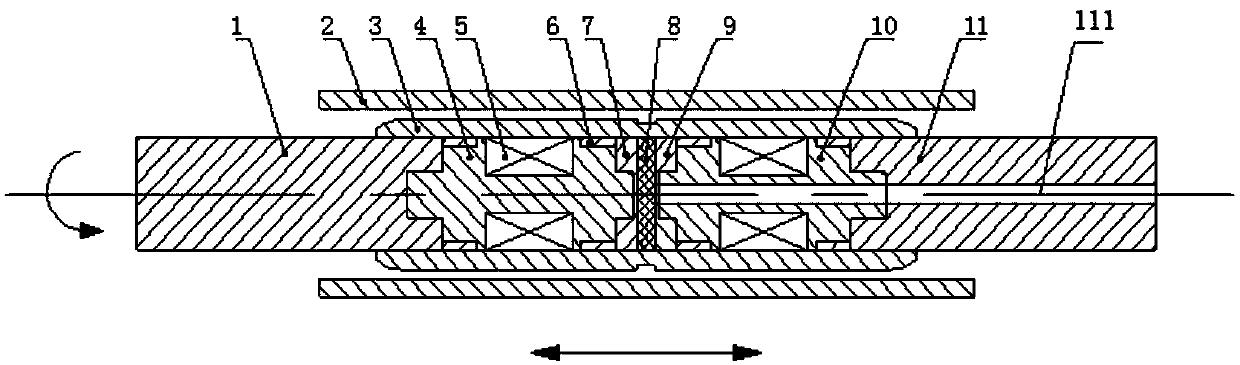

[0022] Such as figure 1 As shown, the composite magnetic field type magnetorheological polishing head of the present invention mainly includes:

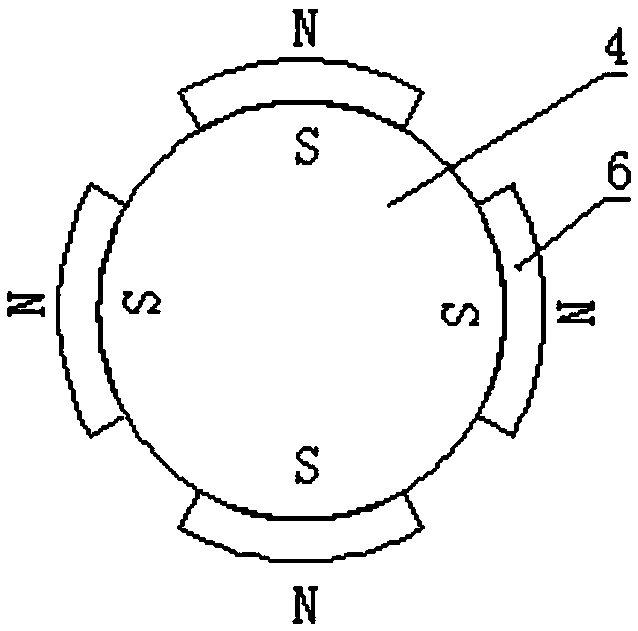

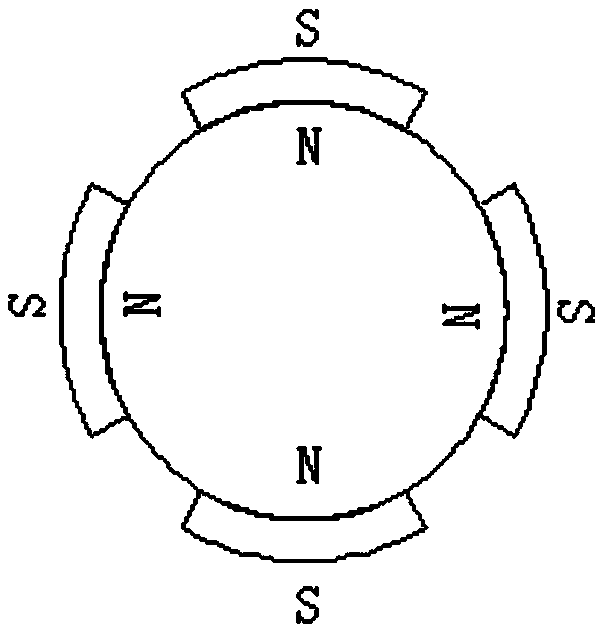

[0023] Transmission shaft 1, workpiece 2, polishing head 3, left iron core 4, excitation coil 5, NdFeB magnetic tile 6, left magnetic isolation plate 7, magnetorheological fluid 8, right magnetic isolation plate 9, right iron core 10, Infusion tube 11, concrete structure is as follows:

[0024] The polishing head 3 is installed at the center of the inner wall of the workpiece 2. The gap between the polishing head 3 and the inner wall of the workpiece 2 is 1mm. Movement, the workpiece 2 makes a reciprocating linear motion relative to the polishing head 3, the left iron core 4 and the right iron core 10 are respectively installed on the left and right sides of the polishing head 3, and the two ends of the left iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com