Daily device disinfection and management control system and control method thereof

A management control and equipment technology, applied in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of time-consuming and laborious, low work efficiency, increasing environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

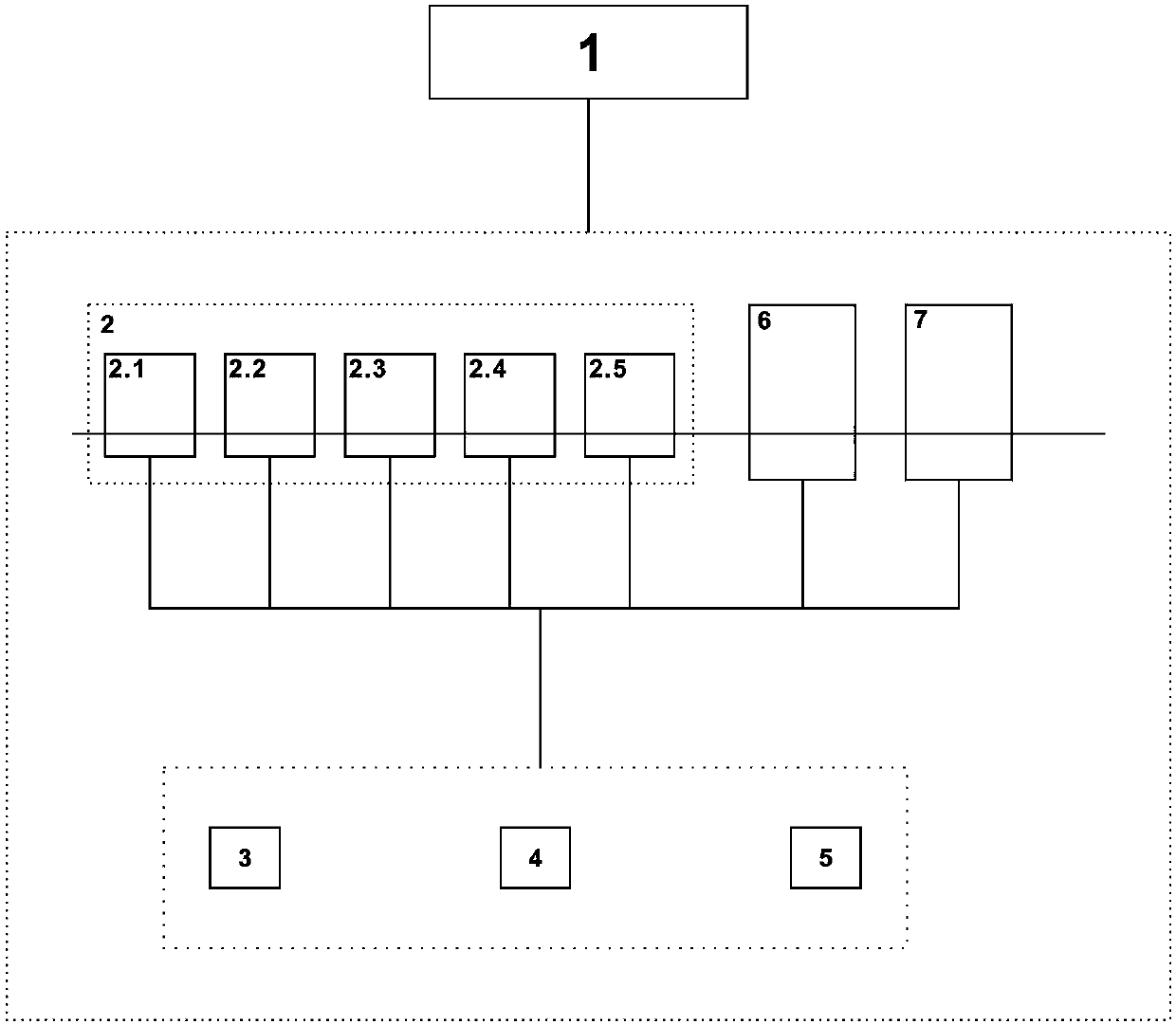

[0072] A daily instrument disinfection management control system, such as figure 1 As shown, the system includes a control center module, a parts disinfection module, a time management module, a failure alarm module, a waste liquid collection module, an ultraviolet disinfection module and an ozone disinfection module;

[0073] The parts disinfection module includes: a high-pressure air flushing dust removal unit, a high-pressure water gun washing unit, a disinfectant soaking disinfection unit, a disinfectant cleaning unit and a drying unit, and the above six units are connected in sequence;

[0074] The control center module includes:

[0075] A three-dimensional scanning unit, the three-dimensional scanning unit is used to measure the three-dimensional structure data of the instrument parts;

[0076] An infrared scanning unit, the infrared scanning unit detects the distribution of contamination on the parts of the device according to the three-dimensional structure data of t...

Embodiment 2

[0124] The content and experimental results of this embodiment are basically the same as in Example 1, except that:

[0125] The working time of the high-pressure air flushing dust removal unit is 15 minutes.

[0126] The working time of the high-pressure water gun flushing unit is 40 minutes.

[0127] The working time of the disinfectant soaking disinfection unit is 15 minutes.

[0128] The working time of the disinfectant cleaning unit is 15 minutes.

[0129] The working time of the drying unit is 15 minutes, and the drying temperature is 70°C.

[0130] The working time of the ultraviolet disinfection module described in step 3) is 30min.

[0131] The working time of the ozone disinfection module described in step 4) is 30min.

Embodiment 3

[0133] The content and experimental results of this embodiment are basically the same as in Example 1, except that:

[0134] The working time of the high-pressure air flushing dust removal unit is 30 minutes.

[0135] The working time of the high-pressure water gun flushing unit is 60 minutes.

[0136] The working time of the disinfectant soaking disinfection unit is 30 minutes.

[0137] The working time of the disinfectant cleaning unit is 30 minutes.

[0138] The working time of the drying unit is 30 minutes, and the drying temperature is 90°C.

[0139] The working time of the ultraviolet disinfection module described in step 3) is 5min.

[0140] The working time of the ozone disinfection module described in step 4) is 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com