Extrusion forming device of multi-color strip polymer steamed rice roll and steamed flour roll machine

An extrusion molding and polymer technology, which is applied to the extrusion molding device of the sausage noodle machine and the field of sausage flour, can solve the problems of the appearance of food with a single color, the taste is not too rich, and the appearance is not very beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment, further illustrate the present invention.

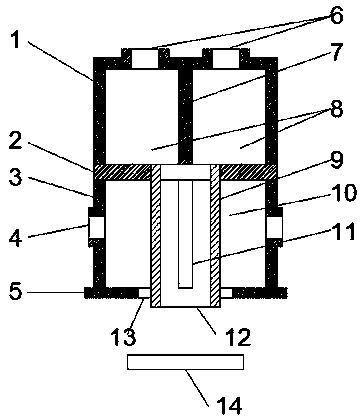

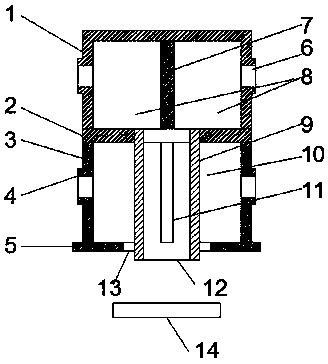

[0028] see Figure 1-Figure 9 , an extrusion molding device for sausage powder and sausage noodle machine made of multi-color strip polymer, consisting of a main body upper part 1 and a main body lower part 3. Fabric, powder chamber 10, core material, filling material chamber 8 and lining, powder chamber 10 are provided with intermediate spacer 2, main body bottom 3 is provided with core material pipe 9, the top of core material pipe 9 and middle spacer 2 connection, the top nozzle of the core material tube 9 communicates with the core material and the stuffing chamber 8, and the bottom end of the core material tube 9 stretches out from the fabric and the powder material chamber 10, and the bottom nozzle of the core material tube 9 is for the core material to squeeze out. Outlet 12, the outer wall of the bottom of the core tube 9 and the lining, powder chamber 10 are provided with lining,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com