Blueberry picking and sorting apparatus and working method

A sorting device and blueberry technology, applied in picking machines, chemical instruments and methods, solid separation, etc., can solve the problems of large drive mass, limited wind power of blower mechanism, and poor ventilation conditions, so as to improve the degree of mechanical automation and reduce labor costs. Labor intensity, the effect of reducing rough processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

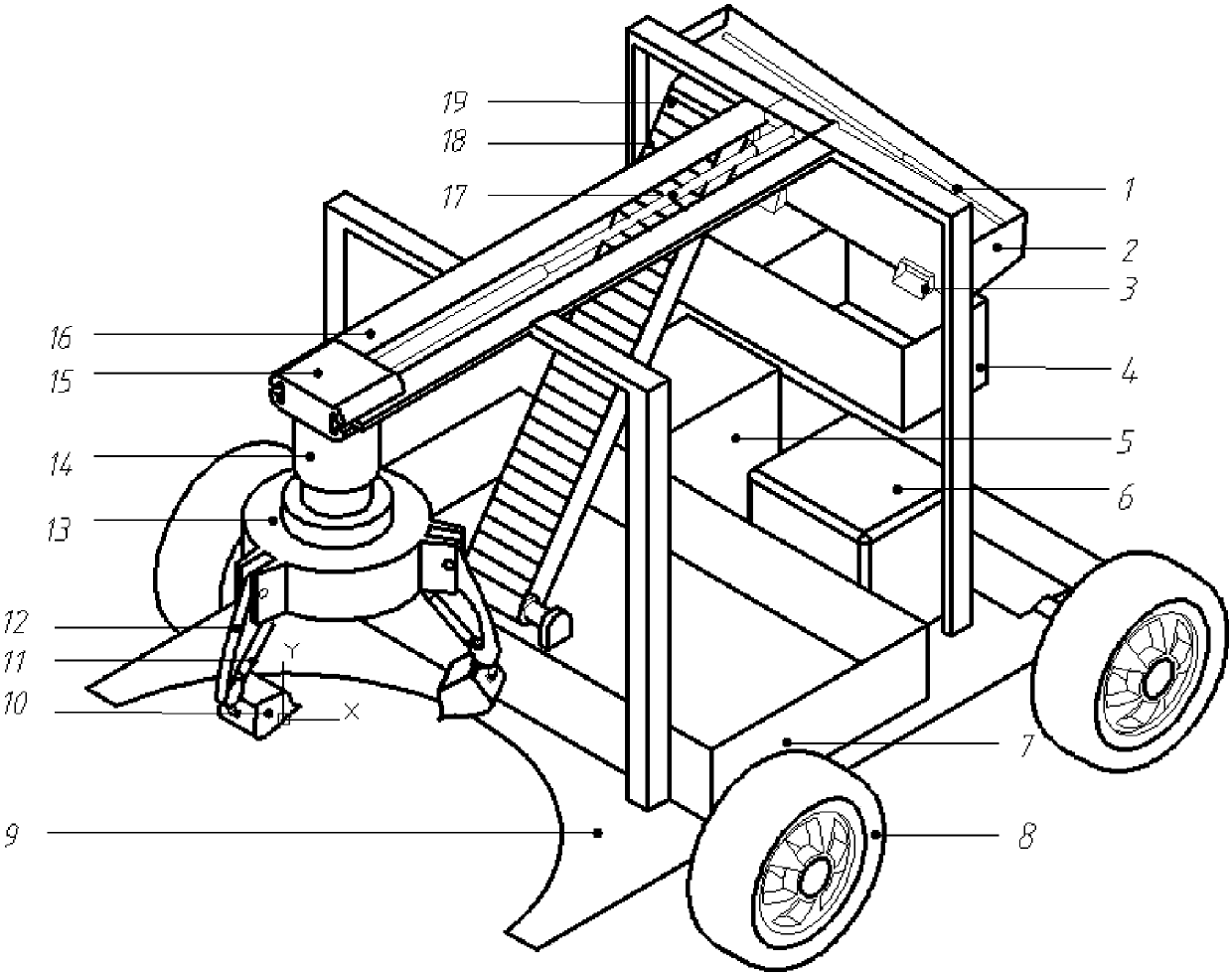

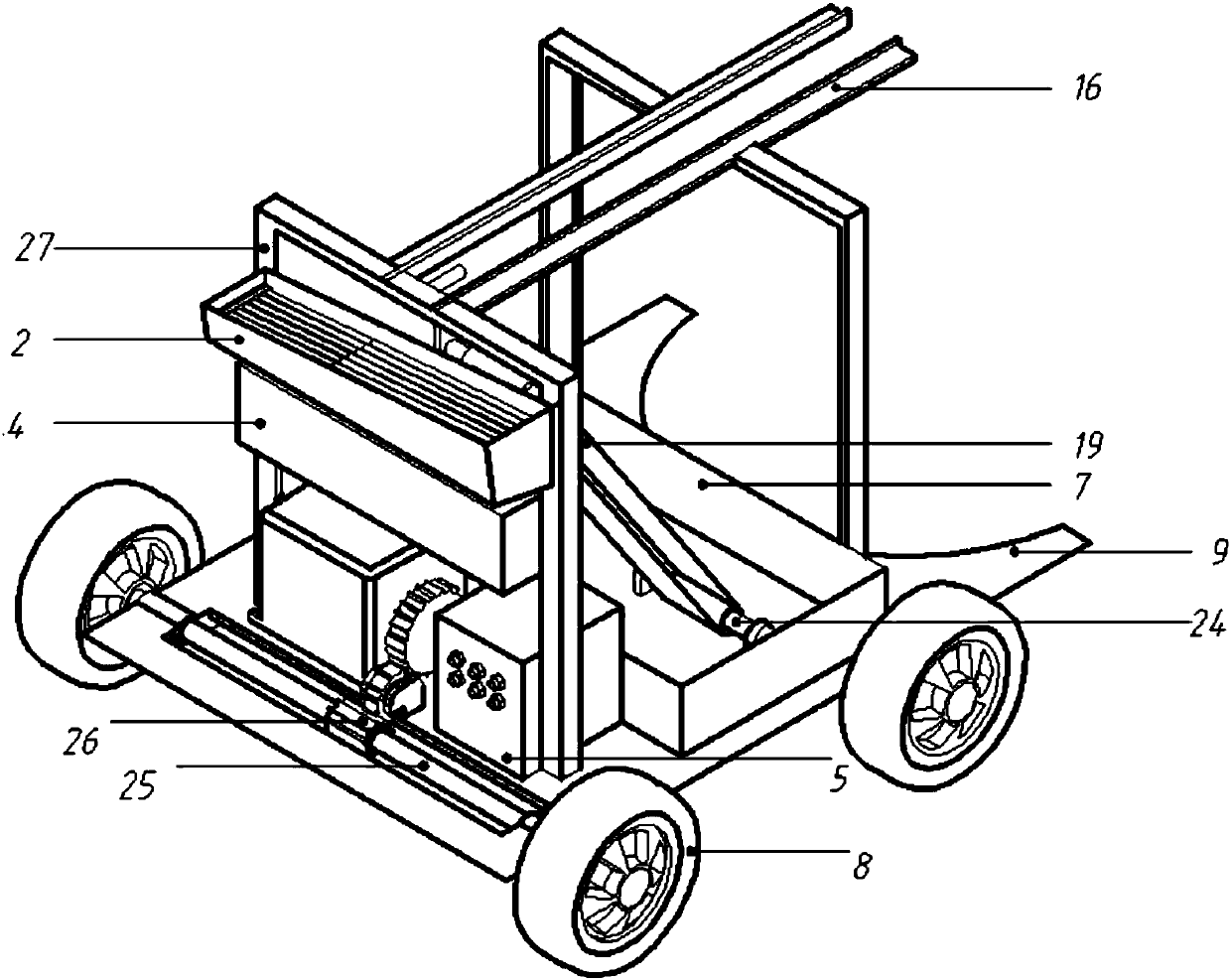

[0046] A blueberry picking and sorting device, comprising an underframe and a frame 27 arranged on the underframe, wheels 8 are arranged at the bottom of the underframe, guide rails 16 are arranged on the top of the frame 27, the guide rails 16 are welded on the frame, and the guide rails The movable connection has a picking device; one end of the frame is equipped with a sorting device;

[0047] The chassis below the guide rail 16 is provided with a collection bin 7, one end of the collection bin is provided with an end of a conveyor belt 19, and the other end of the conveyor belt 19 is located above the sorting device;

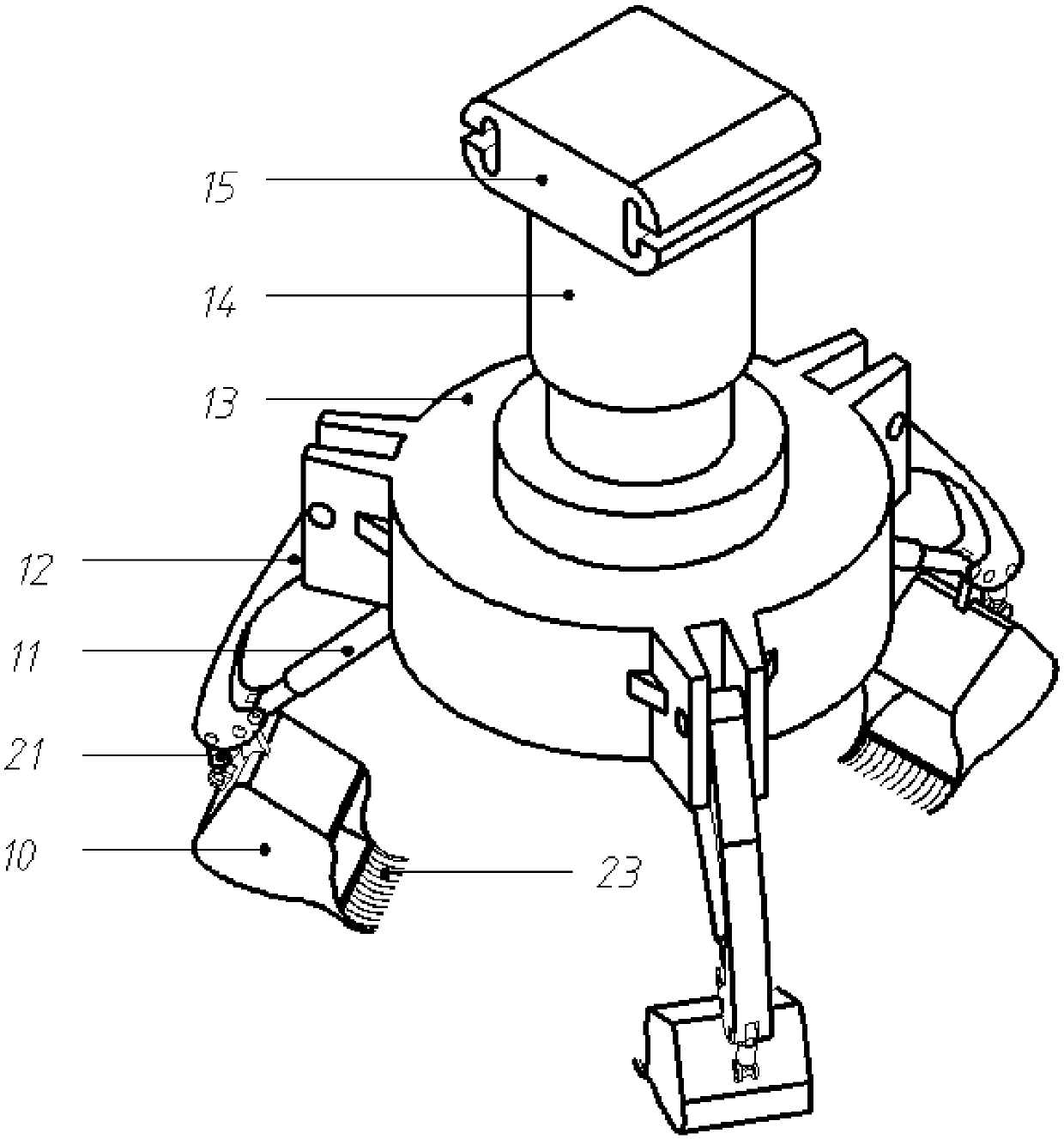

[0048] Picking device comprises guide slider 15, and guide slider 15 is matched with guide rail 16 and is connected, and frame 27 is connected with guide slider 15 by translation cylinder 17, and translation cylinder 17 controls guide slider 15 to move horizontally along guide rail 16, and guide slider 15 There is a lifting cylinder 14 below, and one end of ...

Embodiment 2

[0055] A blueberry picking and sorting device, its structure is as described in Example 1, the difference is that one end of the pull rod is provided with a hinged hole, which is hinged with the base; the other end of the pull rod is an arc-shaped arc head, Such as Figure 6 As shown, the arc head is provided with three hinged holes, and the three hinged holes are respectively hinged with the side pull cylinder, the bucket, and the forward cylinder. The lower part of the link rod is designed with a protruding arc head, the purpose is to facilitate the arrangement of the hinge holes and prevent the three hinges from being squeezed each other, such as Figure 7 shown. The position and angle of the bucket are controlled by the telescopic cooperation of the lifting cylinder, the forward-tilting cylinder, and the side-pull cylinder, and the blueberries are picked into the bucket.

Embodiment 3

[0057] A blueberry picking and sorting device, the structure of which is as described in Embodiment 2, the difference is that the end connected to the base and the pulling rod is provided with a moving slot and a moving seat located in the moving slot, and the moving slots are radially distributed on the base. On the surface of the seat, the movable seat is hinged with one end of the connecting rod, the movable seat is connected with the base through the extension cylinder, and a stroke switch is arranged on the cylinder wall of the side pull cylinder, and the stroke switch is connected with the extension cylinder. The implicated plate can extend radially outward along the base, so as to adjust the area of the base. A travel switch is installed on the cylinder wall of the side pulling cylinder. When the lifting cylinder reaches the maximum stroke, the travel switch is triggered so that the moving seat automatically extends radially outward from the base along the moving groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com