V-shaped road transportation safety guardrail

A technology for safety guardrails and road traffic, which is applied to road safety devices, roads, roads, etc., can solve the problems of long length of the crossbar and inconvenient installation, and achieve the effects of high connection strength, convenient installation, and convenient and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

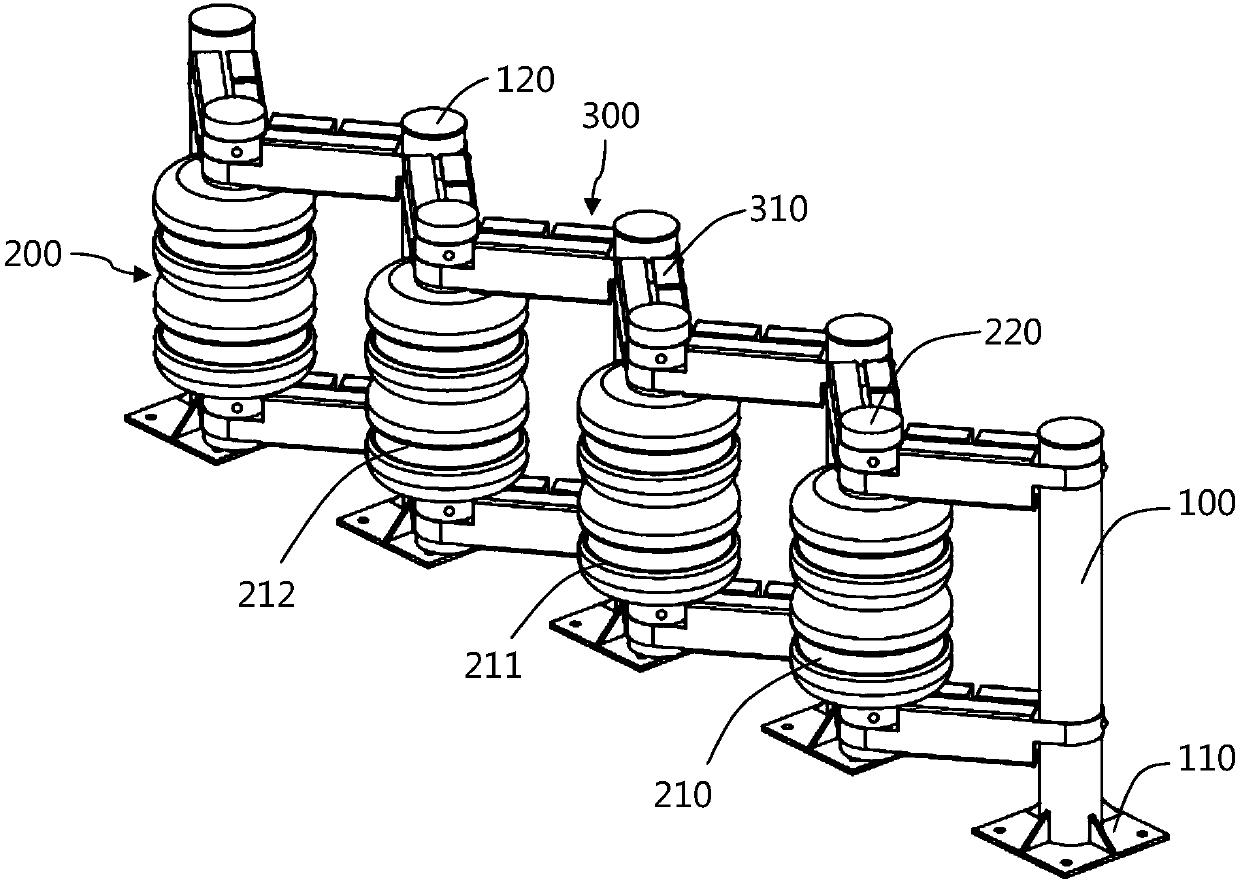

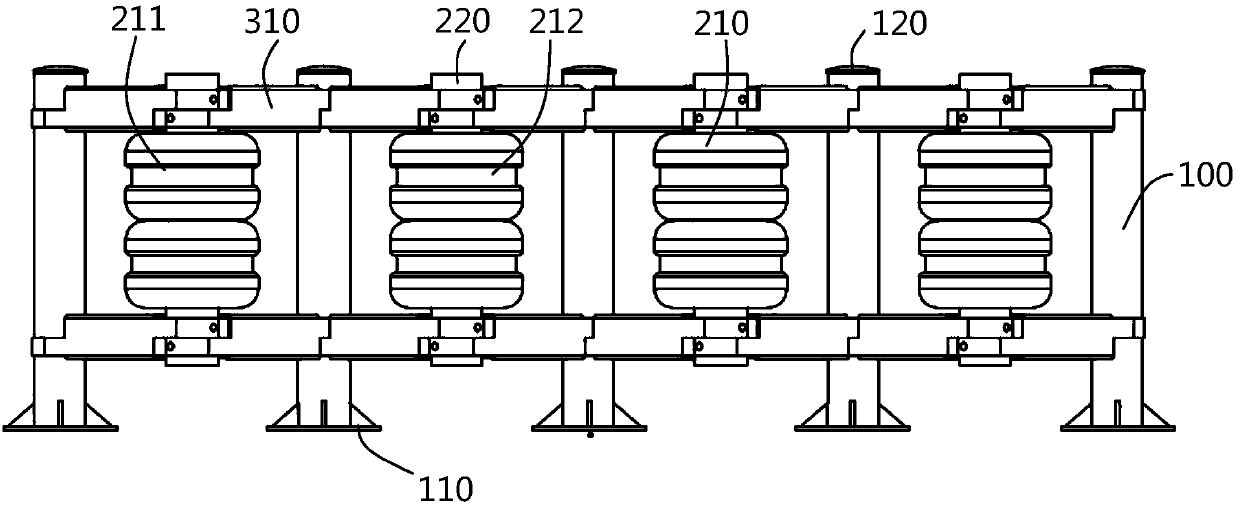

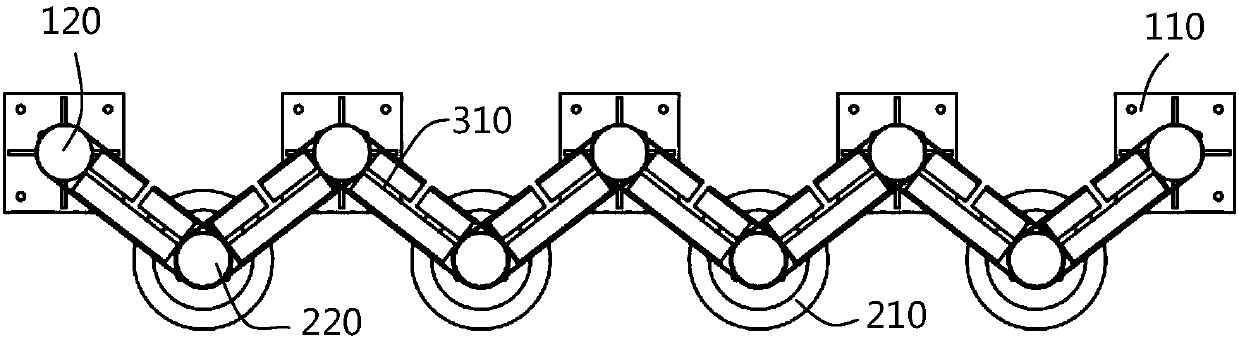

[0037] like Figure 1 to Figure 3 As shown, the V-shaped road traffic safety guardrail of the present invention includes a column 100, an elastic rotating part 200 and a rail 300. The rail 300 is formed by connecting several rail bodies 310. The rail body 310 has two ends, one of which is Fitted on the column 100, the other end is rotatably combined with the elastic rotating part 200, and two adjacent rail bodies 310 are connected by the elastic rotating part 200 to form a V-shaped angle.

[0038]The inventor shortened the railing through a large number of experiments and improved the design of the structure. Two railing bodies 310 are arranged between two adjacent columns 100, and the two railing bodies 310 are connected by elastic rotating parts 200 to form a V-shaped angle. If the long horizontal rail in the prior art is replaced with the horizontal rail composed of the multi-section horizontal rail body of the present invention, the overall strength of the horizontal rail...

Embodiment 2

[0050] like Figure 4 to Figure 6 As shown, a V-shaped road traffic safety guardrail of the present invention includes a column 100, an elastic rotating part 200 and a horizontal bar 300. The horizontal bar 300 has two ends, one of which is sleeved on the column 100, and the other end is rotated and combined with an elastic The rotating part 200, two adjacent rails 300 are connected by the elastic rotating part 200 and form a V shape; the column 100 has a tubular structure and is erected on the side of the road at a constant interval; the elastic rotating part 200 includes an elastic rotating body 210 and a rotating shaft 220 , the shape of the elastic rotating body 210 is a conical body, the top is large and the bottom is small, the taper can be in the range of 3-5°, the best value is 5°, the elastic rotating body 210 has a passage through the elastic rotating body 210 from its upper part to the bottom The rotating shaft 220 is inserted into the through hole of the elastic ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com