Method and system for minimal continuous-flow air-oil lubrication, with electronic regulation and control

A minimum and lubricant technology, applied in the direction of control/regulation system, non-electric variable control, ratio control, etc., can solve the problems of not being able to supply high-pressure fluid, not being able to supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

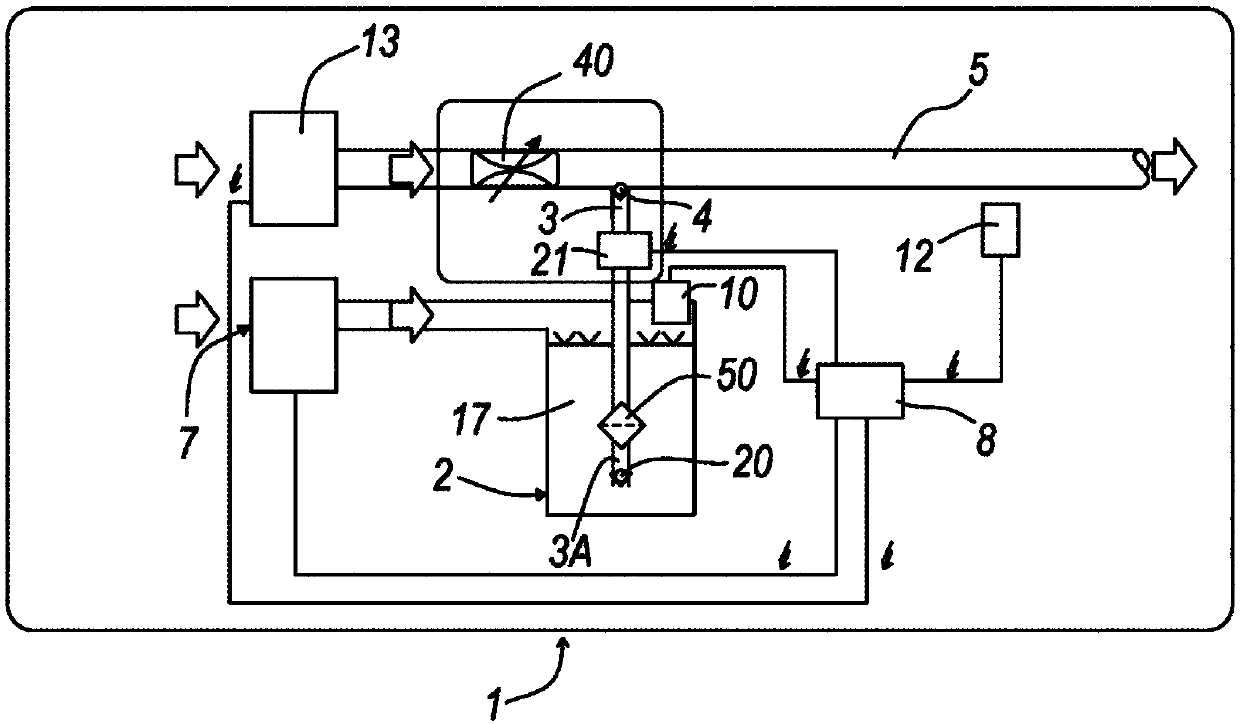

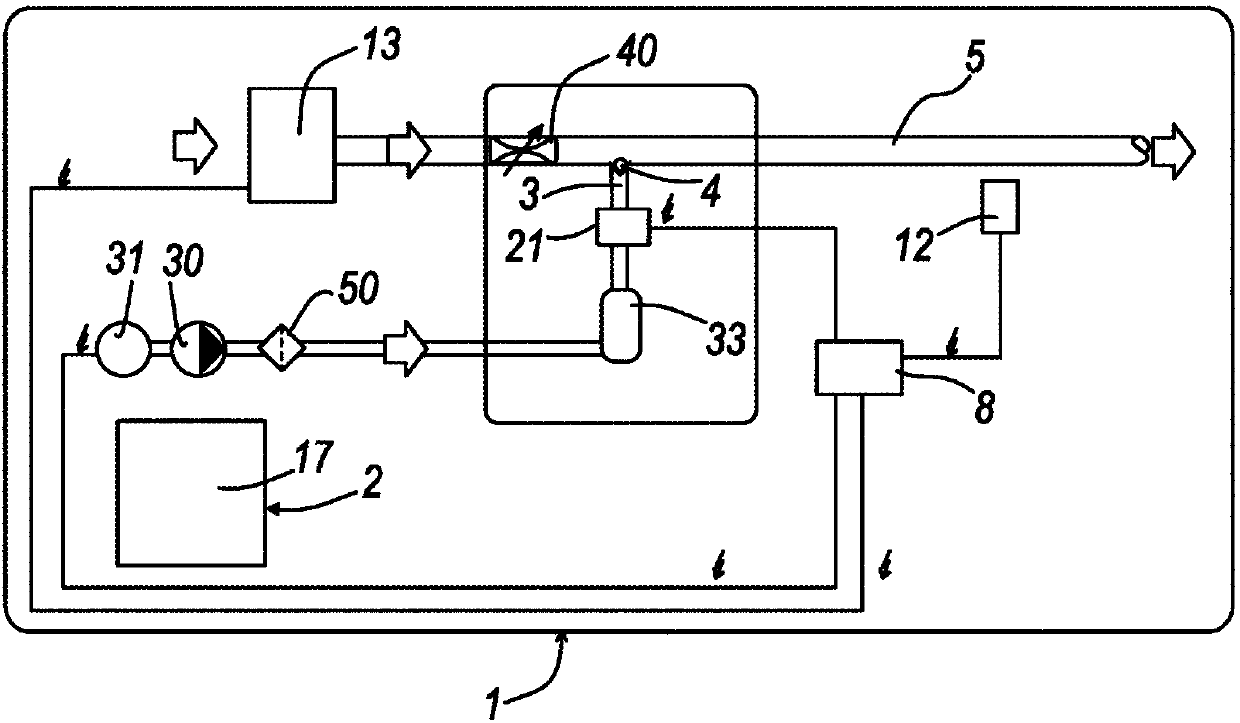

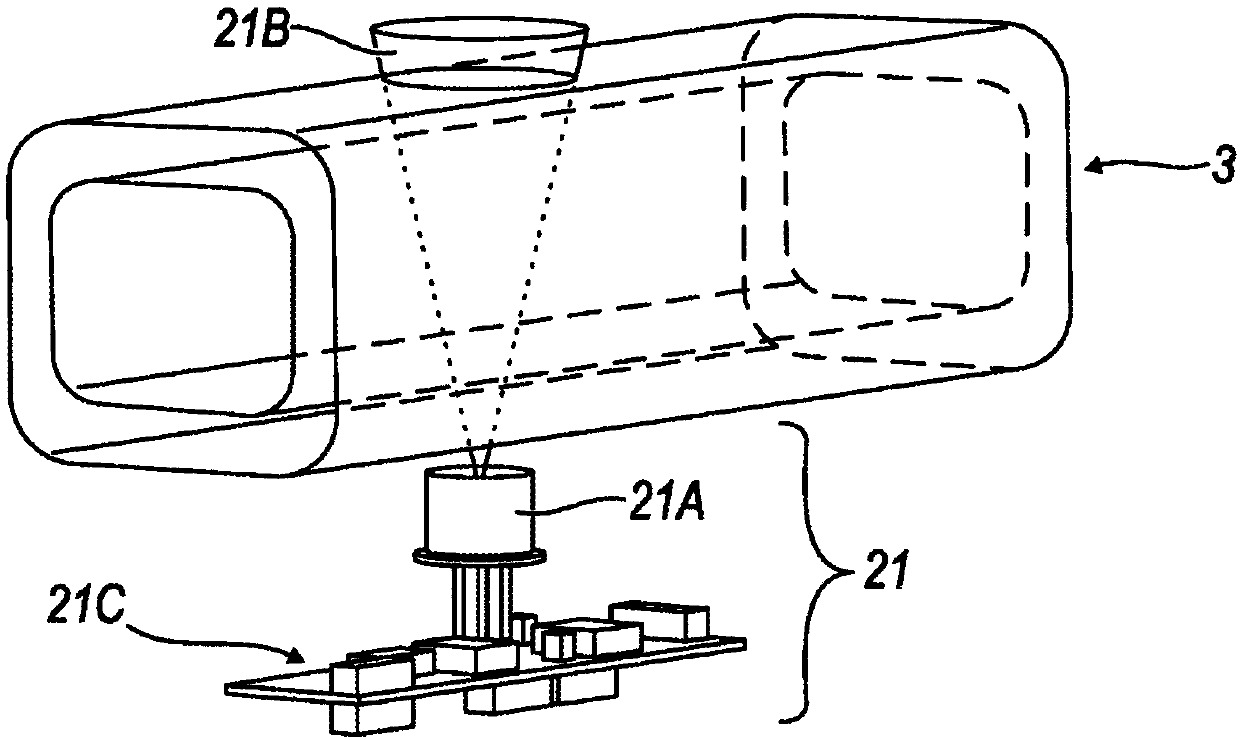

[0025] refer to figure 1 , the system according to the invention for minimal air-oil lubrication of mechanical units is indicated generally with 1 . Such a system comprises a tank 2 containing a first fluid, i.e. lubricant or oil, from which extends a first conduit 3 connected by a one-way valve 4 to the movement of a second conveying fluid in it The second pipeline 5 (for mixing). The right-angled arrangement of the ducts 3 and 5 is only intended as a non-limiting example of the invention, as these ducts may be arranged at different angles.

[0026] The tank 2 is connected to a pressure regulator 7 which generates a pressure in the tank 2 in order to obtain a predetermined flow of the first fluid or lubricant in the pipe 3 . The pressure regulator is connected to a command and control unit 8 , preferably with a microprocessor, which controls the operation of the system 1 .

[0027] This unit is also connected to a pressure sensor 10, which detects the pressure of the lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com