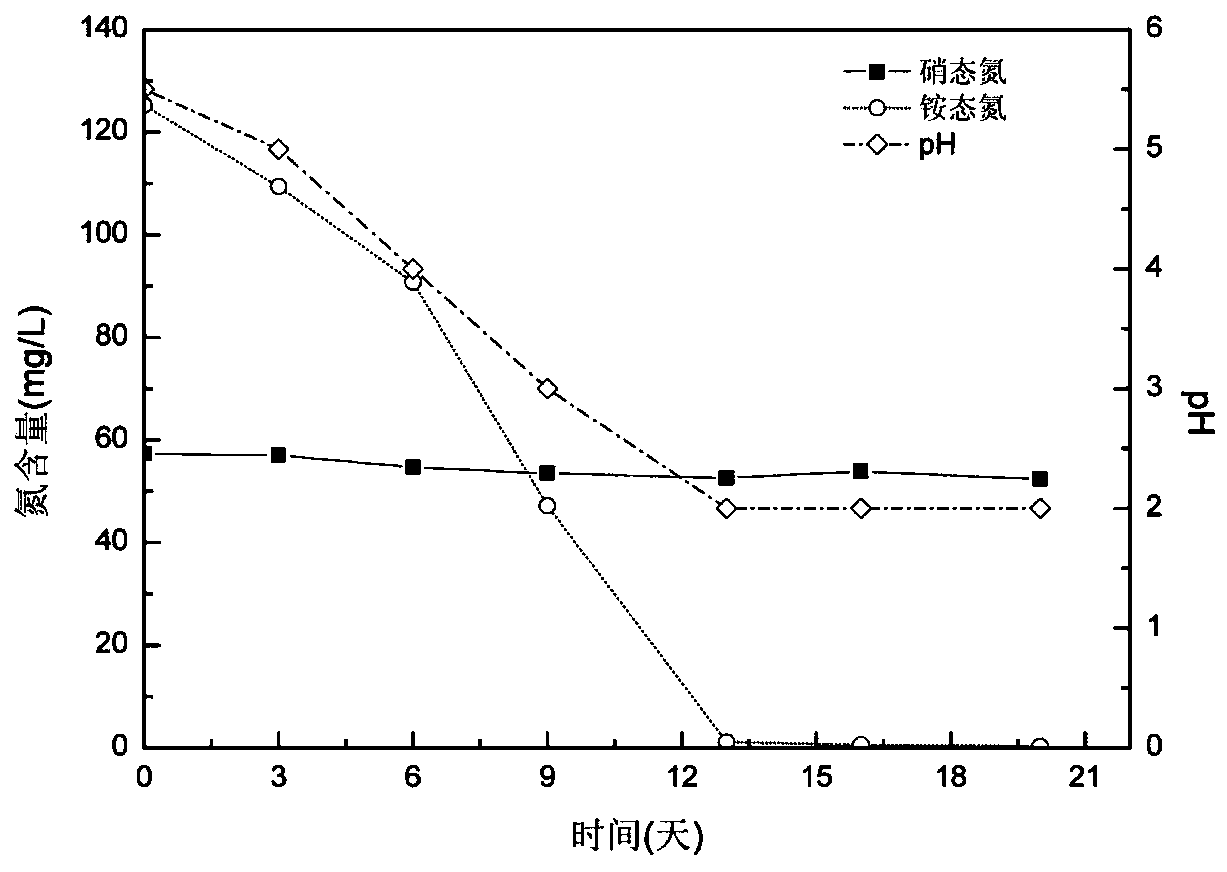

An orange algae artificial turf and its application in coupling ammonium nitrogen wastewater treatment and carotenoid production

A technology of artificial turf and orange algae, applied in the biological field, can solve the problems of low cell adhesion strength of algal biofilm, easy detachment of cells from the attached matrix, and reduced pollutant removal rate, etc., and achieves easy popularization, simple method and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] An orange algae artificial turf, the preparation method comprising: (1) breaking the orange algae into segmented algae filaments; (2) mixing the algae filaments with a liquid medium and a thickener; (3) mixing the mixed algae The uniform solution is sprayed on the surface of the matrix to form an algae film; (4) the algae film is cultivated for 5-10 days in suitable light intensity, temperature, ambient humidity and air enriched with carbon dioxide to form artificial turf with erect algae filaments.

[0040] Preferably, the orange algae is selected from strains of the family Chrysophyceae of the order Chlorophyceae Citrus, preferably selected from the strains of the genus Citrus and the genus Cephalosporin.

[0041] More preferably, the orange algae is selected from arboreal orange algae, golden orange algae, and Cephalosporium.

[0042] Preferably, the segmented algae filaments have a length in the range of 50-500 microns.

[0043] Preferably, the thickener is selecte...

Embodiment 1

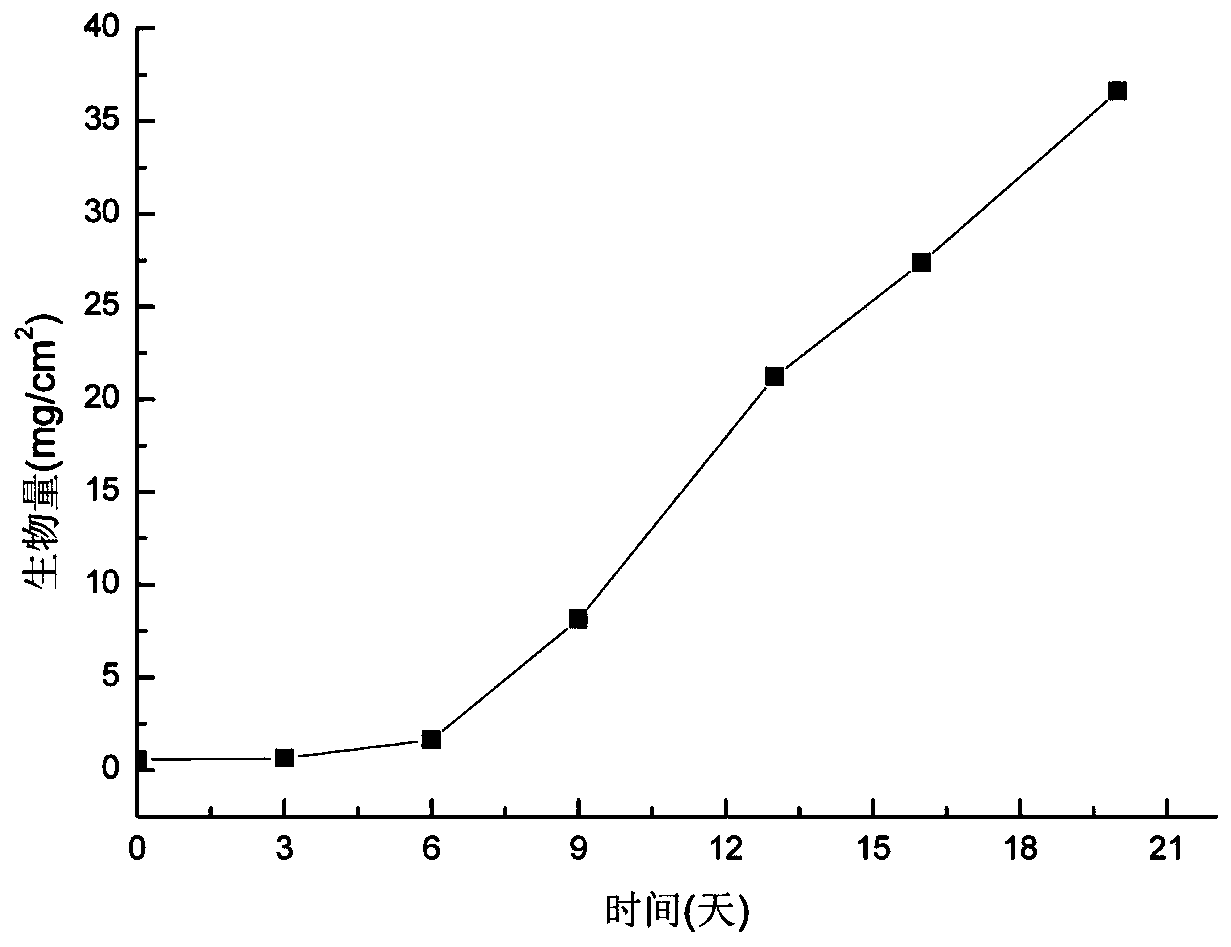

[0050] Cultivate the golden orange algae to the logarithmic phase by liquid suspension, collect the plants and use a high-speed dispersing homogenizer to shear and disperse them. After running at a low speed for 1 minute, the length of the algae filaments in the mixed solution is in the range of 50-500 μm; then to the algae Add 50 times the volume of BBM medium and 0.1wt% xanthan gum to the silk and mix well, use a watering can to spray the mixed solution on the surface of the filter cloth to form an algae film; further, place the algae film at 30 μmol / m 2 Under the light intensity of / s and the temperature of 25°C, spray an appropriate amount of water to keep the algae film in a moist state, cultivate it for 10 days, and form artificial turf with upright algae filaments, and the thickness of the biofilm reaches 7.5mm.

Embodiment 2

[0052] Collect Cephaleuros plants, use a high-speed dispersing homogenizer to shear and disperse the plants, and obtain the length of algae filaments in the mixed solution in the range of 50-500 μm; add a certain volume of BBM medium to make the final concentration of algae filaments reach about 1g / L, add 0.1% sodium alginate and mix well, then sprinkle on the surface of the thin layer of sponge until the obvious green algae film is seen; then hang the sponge in a glass chamber, and enter the liquid BBM culture from the top of the sponge Base, and air containing 1% carbon dioxide was introduced into the chamber to provide 30μmol / m 2 / s light culture for 7 days, the length of upright algae filaments on the surface of the sponge reaches 10mm, and the preparation of orange algae artificial turf is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com