Preservative film and preparation method thereof

A technology of fresh-keeping film and adsorbent, which is applied in the field of fresh-keeping, which can solve the problems of short fresh-keeping time, impact on human health, and poor fresh-keeping effect, and achieve the effects of prolonging the fresh-keeping time, improving the utilization rate of raw materials, and ensuring safety and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

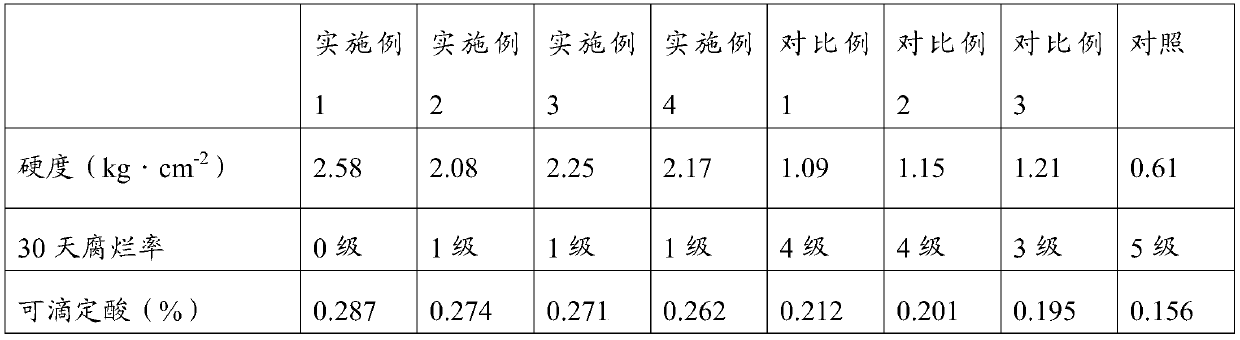

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned plastic wrap according to an embodiment of the present invention comprises the following steps S1-S3:

[0030] S1. Coating an ethanol solution of hollow porous polymer microspheres on the resin base film.

[0031] S2, mixing the adsorbent with water to obtain a slurry, coating the slurry on the resin base film and drying to form an ethylene adsorption layer.

[0032] S3, forming a waterproof and breathable layer on the vinyl adsorption layer.

[0033] Preferably, the mass percent concentration of the adsorbent in the slurry is 0.2% to 1%. If the concentration is too high, it will be difficult for the adsorbent to fully enter the hollow porous polymer microspheres. If the concentration is too low, the adsorption effect will be reduced.

[0034] In one embodiment, the above-mentioned drying specifically includes the following steps: drying at 15-25°C for 5-6 hours, and then drying at 50-80°C for 1-3 hours. In this way, first...

Embodiment 1

[0039] The ethanol solution of hollow porous polymer microspheres is coated on the resin base film, and the material of the hollow porous polymer microspheres is acrylate copolymer. The adsorbent was obtained by weighing each component according to the following mass percentages: 62% potassium permanganate, 27% methylcyclopropene, 8% chromium trioxide, 2% activated carbon and 1% montmorillonite. Mix the adsorbent with water to obtain a slurry, the mass percent concentration of the adsorbent is 0.5%, coat the slurry on the resin base film, then put it into an environment of 20°C for slow drying for 5 hours, and then put it in an oven at 60°C Dry for 2 hours to form an ethylene adsorption layer. Finally, coated with expanded polytetrafluoroethylene on the ethylene adsorption layer to form a waterproof and air-permeable layer to obtain a fresh-keeping film, wherein the thickness of the resin base film is 10 μm, the thickness of the ethylene adsorption layer is 3 μm, and the thick...

Embodiment 2

[0041] The ethanol solution of hollow porous polymer microspheres is coated on the resin base film, and the material of the hollow porous polymer microspheres is acrylate copolymer. Mix potassium permanganate with water to obtain a slurry, the mass percent concentration of potassium permanganate is 0.5%, coat the slurry on the resin base film, and then put it into an environment of 20°C for slow drying for 5 hours, and then put it in Dry in an oven at 60°C for 2 hours to form an ethylene adsorption layer. Finally, the expanded polytetrafluoroethylene is covered and coated on the ethylene adsorption layer to form a waterproof and breathable layer to obtain a fresh-keeping film, wherein the thickness of the resin base film is 10 μm, the thickness of the ethylene adsorption layer is 3 μm, and the thickness of the waterproof and breathable layer is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com