Push-and-pull reinforcing steel bar drawing force-bearing mechanism

A technology of steel bars and force shafts, which is applied in the field of push-pull steel bar drawing force mechanisms, can solve the problems of small objects falling, high heat production of strip coils, electromagnetic induction interference, etc., to save time and work accuracy Higher, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

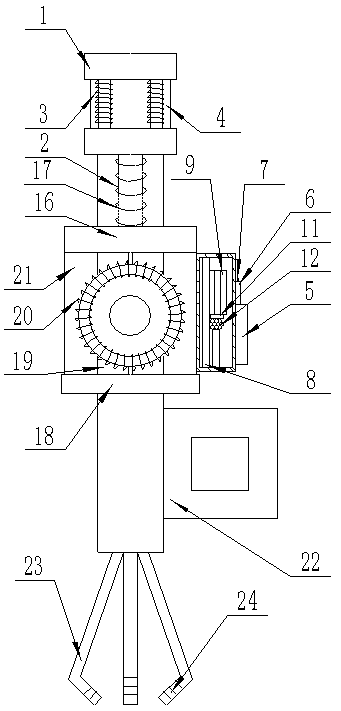

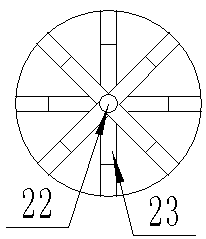

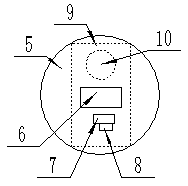

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a push-pull steel bar drawing force-bearing mechanism includes a booster shaft (1), a telescopic rod (2) is provided on one side of the booster shaft (1), and a booster is wound around the booster shaft (1) (3), the booster (3) is nested with a booster ring (4), the booster ring (4) is provided with a booster housing (5), and the upper surface of the booster housing (5) A dual-control function touch switch system is provided. The dual-control function touch switch system is provided with a force-sensing button (6) on the upper surface of the booster housing (5), and is set at the lower end of the force-sensing button (6). The backlight indicator light (7), the warning device (8) set on the left side of the backlight indicator light (7), the PCB circuit board (9) set in the booster housing (5), set on the PCB circuit board (9) The intelligent controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com