Multi-stage screening device

A screening device and secondary screening technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problem of inability to guarantee the quality of powder screening, and achieve the effect of ensuring stability, ensuring screening effect, and ensuring screening quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

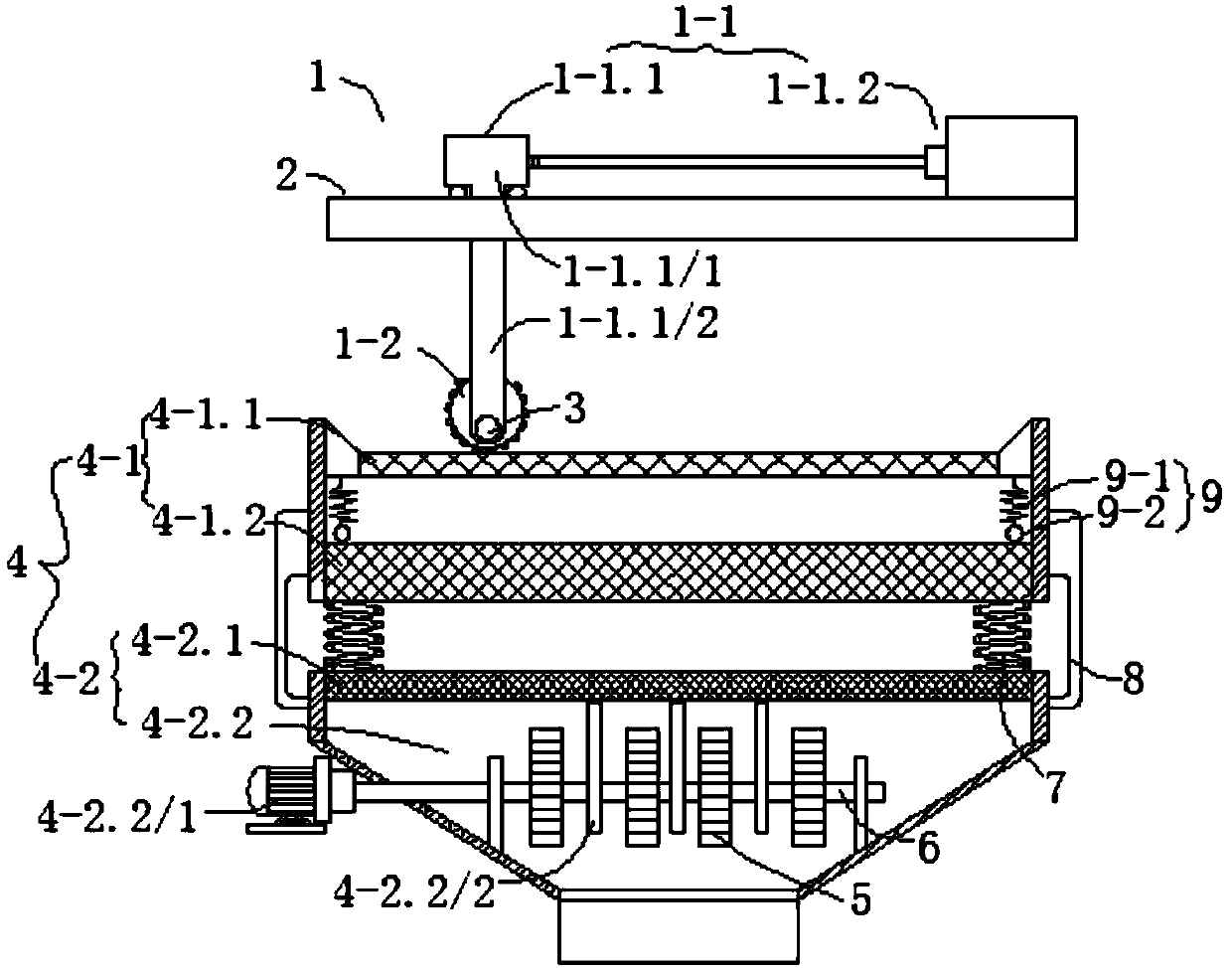

[0023] like figure 1 As shown, this embodiment provides a multi-stage screening device, including a screening hopper 4, and the screening hopper 4 includes a primary screening mechanism 4-1 and a secondary screening mechanism 4-2 arranged in sequence from top to bottom. The primary screening mechanism 4-1 includes the feeding screen 4-1.1 and the secondary screen 4-1.2 arranged in sequence from top to bottom. Above the feeding screen 4-1.1 is a reciprocating rolling assembly 1, and the reciprocating rolling assembly 1 includes a Roller 1-2 and moving assembly 1-1, above the feeding screen 4-1.1 is provided with a load-bearing plate 2 parallel to the feeding screen 4-1.1, the moving assembly 1-1 includes a moving bracket 1-1.1 and a load-bearing plate 1-1. The driving cylinder 1-1.2 on the plate 2 is used to drive the moving bracket 1-1.1. The moving bracket 1-1.1 includes a horizontal connecting plate 1-1.1 / 1 fixedly connected with the piston rod of the driving cylinder 1-1.2 ...

Embodiment 2

[0027] This embodiment is further optimized on the basis of Embodiment 1, specifically:

[0028] A horizontal rotating shaft 6 is provided below the tertiary screen 4-2.1, and the vibration assembly 4-2.2 includes a motor 4-2.2 / 1 that drives the horizontal rotating shaft 6 to rotate and an eccentric wheel group 4-2.2 / 2 that is keyed on the horizontal rotating shaft 6. , two connecting ears 8 are symmetrically arranged between the primary screening mechanism 4-1 and the secondary screening mechanism 4-2, and two guide grooves are symmetrically dug on the side wall of the primary screening mechanism 4-1, and the connecting ears 8 One end is fixedly connected with the secondary screening mechanism 4-2, and the other end is slidingly matched with the guide groove, which ensures the stability of the device during the vibration screening process.

Embodiment 3

[0030] like figure 2 and image 3 As shown, this embodiment is further optimized on the basis of Embodiment 2, specifically:

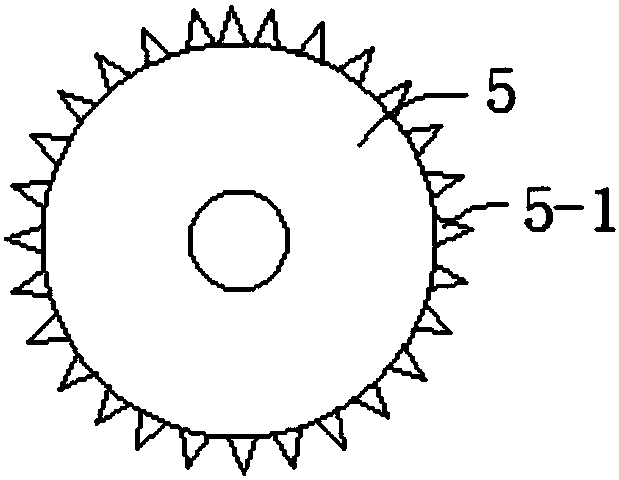

[0031] There are wavy rolling teeth 1-2.1 evenly distributed on the outer circumference of the pressing roller 1-2, and a number of scrap gears 5 are keyed on the horizontal shaft 6, and the scrap gear 5 is evenly distributed on the outer circumference. The crushing gear 5-1 can further crush the powder through the crushing gear 5 to ensure the screening effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com