Production method of water-soluble iodine/selenium/cobalt premix agent

A production method and water-soluble technology, applied in the production field of mixed feed additives, can solve problems such as difficulty in adapting to liquid feed requirements, poor water solubility and uniformity, and meet the requirements of water solubility and uniformity, mixing uniformity The effect of improving and strengthening adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

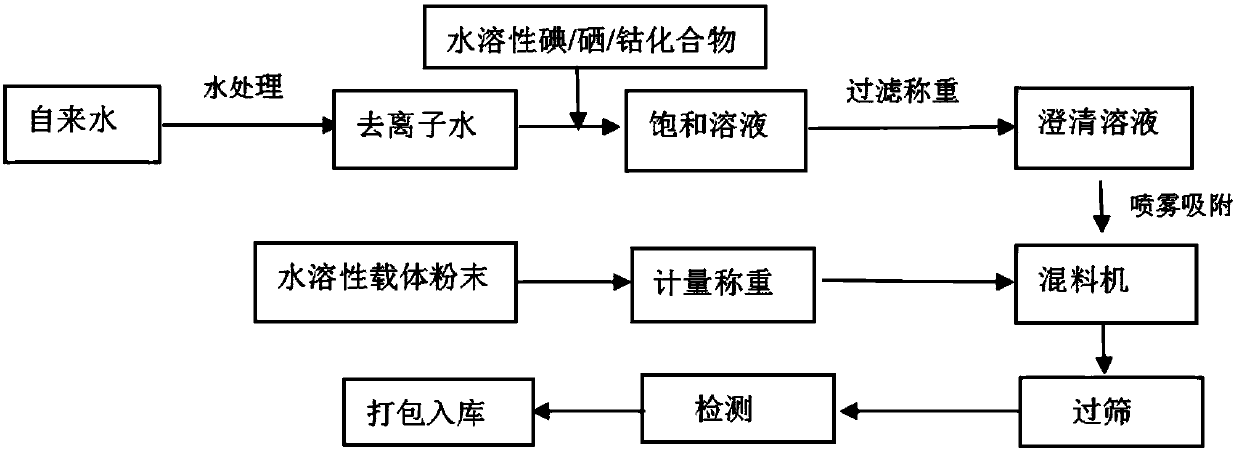

Method used

Image

Examples

Embodiment 1

[0028] Produce water-soluble iodine premix as follows:

[0029] (1) Potassium iodate is dissolved in water to obtain a saturated solution of potassium iodate;

[0030] (2) remove insoluble matter in potassium iodate saturated solution through 120 mesh screens, obtain potassium iodate clarified solution;

[0031] (3) Measure the water-soluble starch according to the ratio that the mass percentage of iodine in the premix after mixing is 1%, and the 70-mesh sieve passing rate of the water-soluble starch is 93%;

[0032] (4) Place the above-mentioned water-soluble starch in a sealable mixer, start the mixing equipment, and control the mixing rate at 20r / min. Spray the mist of above-mentioned potassium iodate clarified solution evenly on the water-soluble starch by the mouth to make it mix evenly.

[0033] (5) Sampling and testing the premix after mixing is completed. After passing the test, a certificate of conformity is issued, packed, and transferred to the finished product wa...

Embodiment 2

[0035] Water-soluble selenium premix is produced according to the following method:

[0036] (1) sodium selenite is dissolved in water to obtain a saturated solution of sodium selenite;

[0037] (2) remove the insolubles in the sodium selenite saturated solution through a 120 mesh screen to obtain a sodium selenite clarified solution;

[0038] (3) Measure corn dextrin according to the ratio that the mass percentage of selenium in the premix after mixing is 1%, and the 80-mesh sieve passing rate of said corn dextrin is 97%;

[0039](4) the above-mentioned corn dextrin is placed in the mixer, start the mixing equipment, control the mixing rate at 18r / min, in the mixing process, spray the corn through the spray nozzle airtightly connected with the mixing chamber Evenly spray the above-mentioned sodium selenite clear solution mist on the dextrin to make it mix evenly.

[0040] (5) Sampling and testing the premix after the mixing is completed, issuing a certificate of conformit...

Embodiment 3

[0042] Water-soluble cobalt premix is produced according to the following method:

[0043] (1) Cobalt sulfate is dissolved in water to obtain a saturated solution of cobalt sulfate;

[0044] (2) remove the insolubles in the cobalt sulfate saturated solution through a 120 mesh screen to obtain a cobalt sulfate clarified solution;

[0045] (3) Measure the microcrystalline cellulose according to the proportion that the mass percent of cobalt in the premix after mixing is 1%, and the passing rate of the 80 mesh sieve of the microcrystalline cellulose is 98%;

[0046] (4) the above-mentioned microcrystalline cellulose is placed in the mixer, start the mixing equipment, control the mixing rate at 20r / min, and in the mixing process, spray the spray nozzle airtightly connected with the mixing chamber to the Spray the above-mentioned cobalt sulfate clarified solution mist evenly on the microcrystalline cellulose to make it mix evenly.

[0047] (5) Sampling and testing the premix af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com