A Coal Blending Method for Stable Coke Quality

A technology of coke quality and coal blending, applied in the field of coking, can solve problems such as inability to detect and quantify ash content, sulfur content, and quality supervision and control of mixed coal, so as to avoid fluctuations in coke quality, scientific supervision of coal blending quality, and accurate supervision of coal blending degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

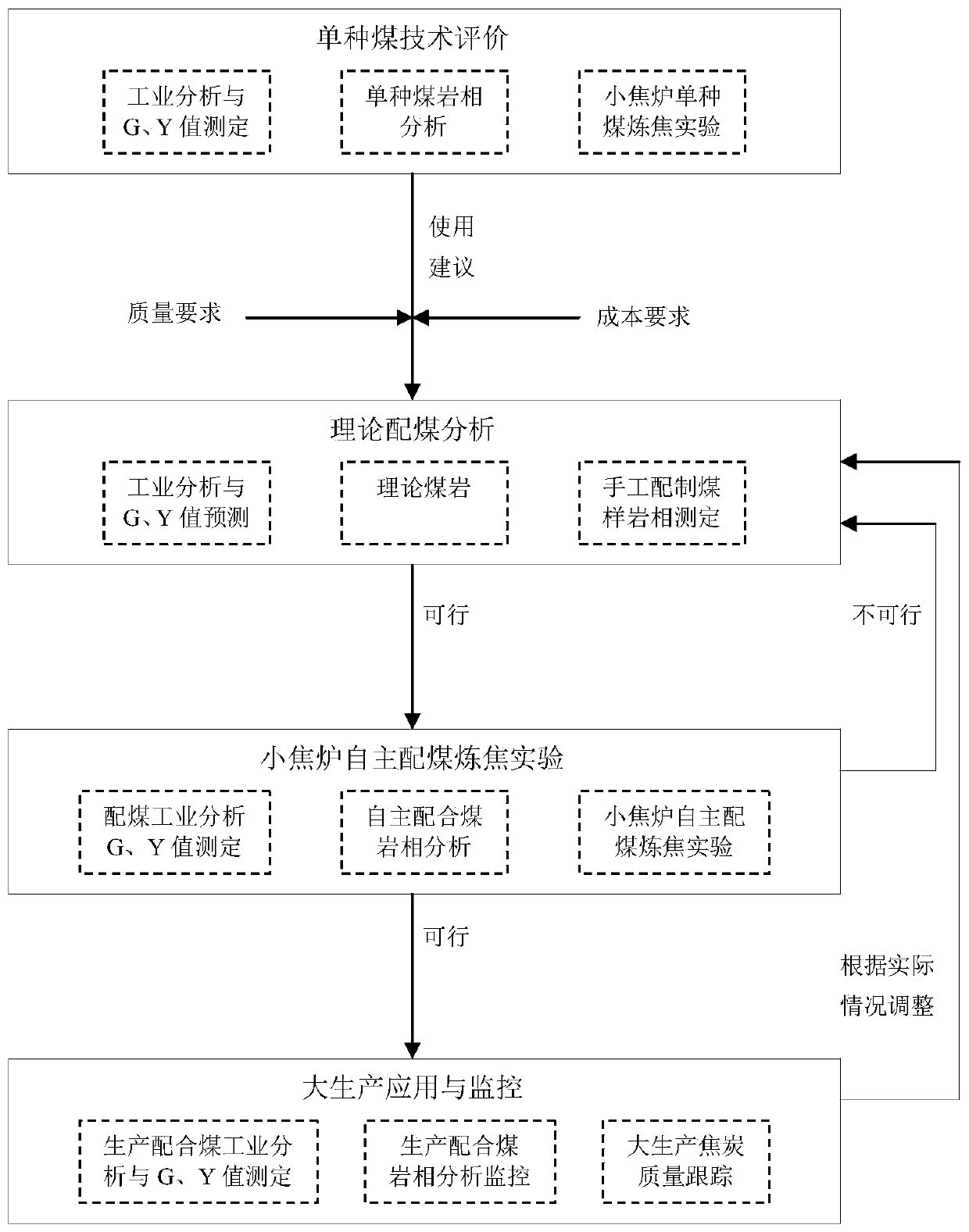

[0017] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0018] Such as figure 1 As shown, a coal blending method to stabilize coke quality, the specific method is as follows:

[0019] 1) Industrial analysis of various coking coals used, determination of G and Y values, coal rock analysis, and independent coking experiment of a single coal in a 40kg small coke oven; industrial analysis indicators of various coal types, G, Y values, maximum Vitrinite reflectance and distribution map, comprehensive analysis and evaluation of coke quality, forming a coking coal technology evaluation database, providing basic data for the rational use of various coal types, providing basic data for the rational use of various coal types, and providing basic data for the newly introduced Coal types or the latest batch of industrial analysis indicators, G, Y values, maximum vitrinite reflectance and distribution maps and coke quality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com