Optical-fiber wire drawing device with automatic feeding and foreign matter adsorption function

A technology that absorbs impurities and automatically feeds materials. It is applied in the field of optical fiber equipment, which can solve problems such as limited effects, reduced work efficiency, and oily smoke, and achieves the effects of avoiding time waste, improving practicability, and expanding the scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

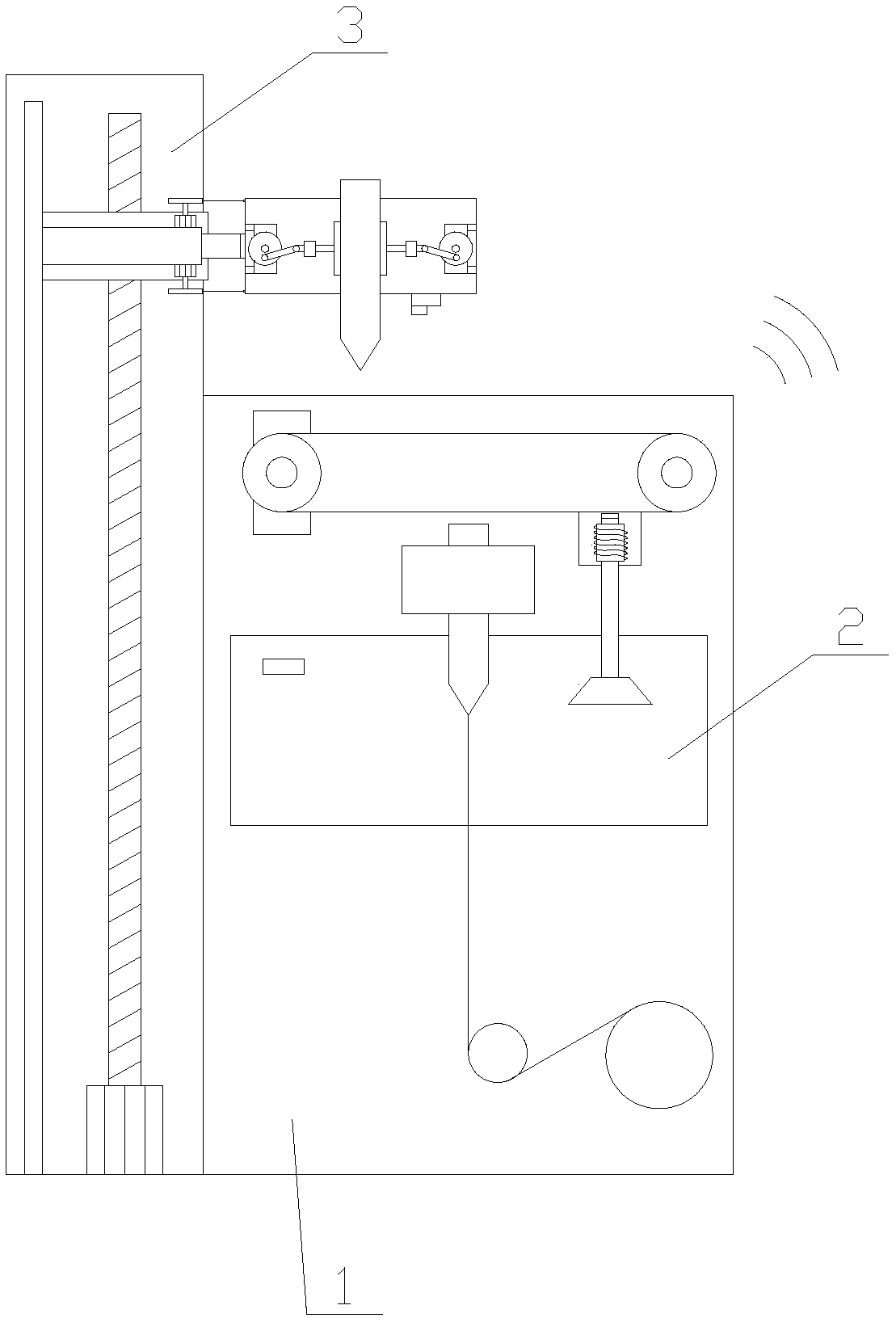

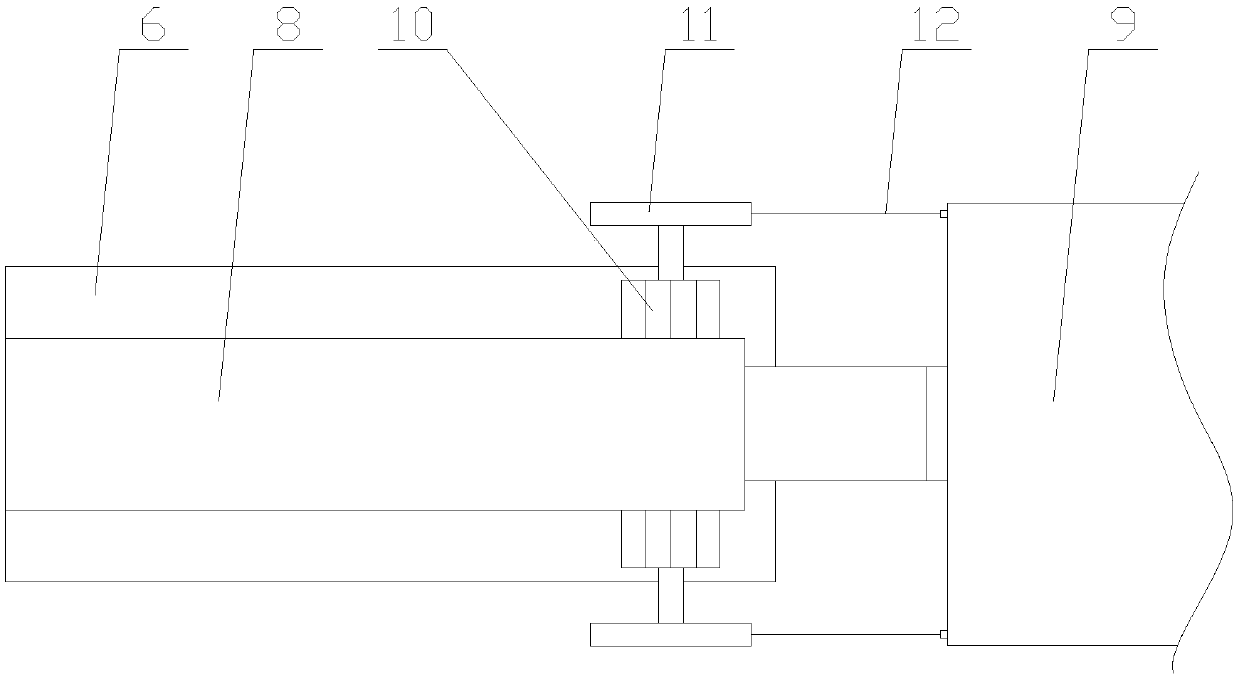

[0029] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0030] like figure 1 As shown, a kind of optical fiber drawing equipment with automatic feeding and absorbing impurity functions includes a main body 1, a heating chamber 2 and a housing 3, and also includes a feeding mechanism and an absorption mechanism. The heating chamber 2 is arranged inside the main body 1, and the The casing 3 is vertically arranged on one side of the main body 1, the feeding mechanism is arranged inside the casing 3, and the absorption mechanism is arranged inside the main body 1;

[0031] The feeding mechanism includes a lifting assembly, an adjusting assembly and a fastening assembly, the lifting assembly is arranged inside the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com