Conveying device

A conveying device and conveyor belt technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of oil mist scattering, unsatisfactory sanitation, strong odor, etc., and achieve the effect of suppressing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

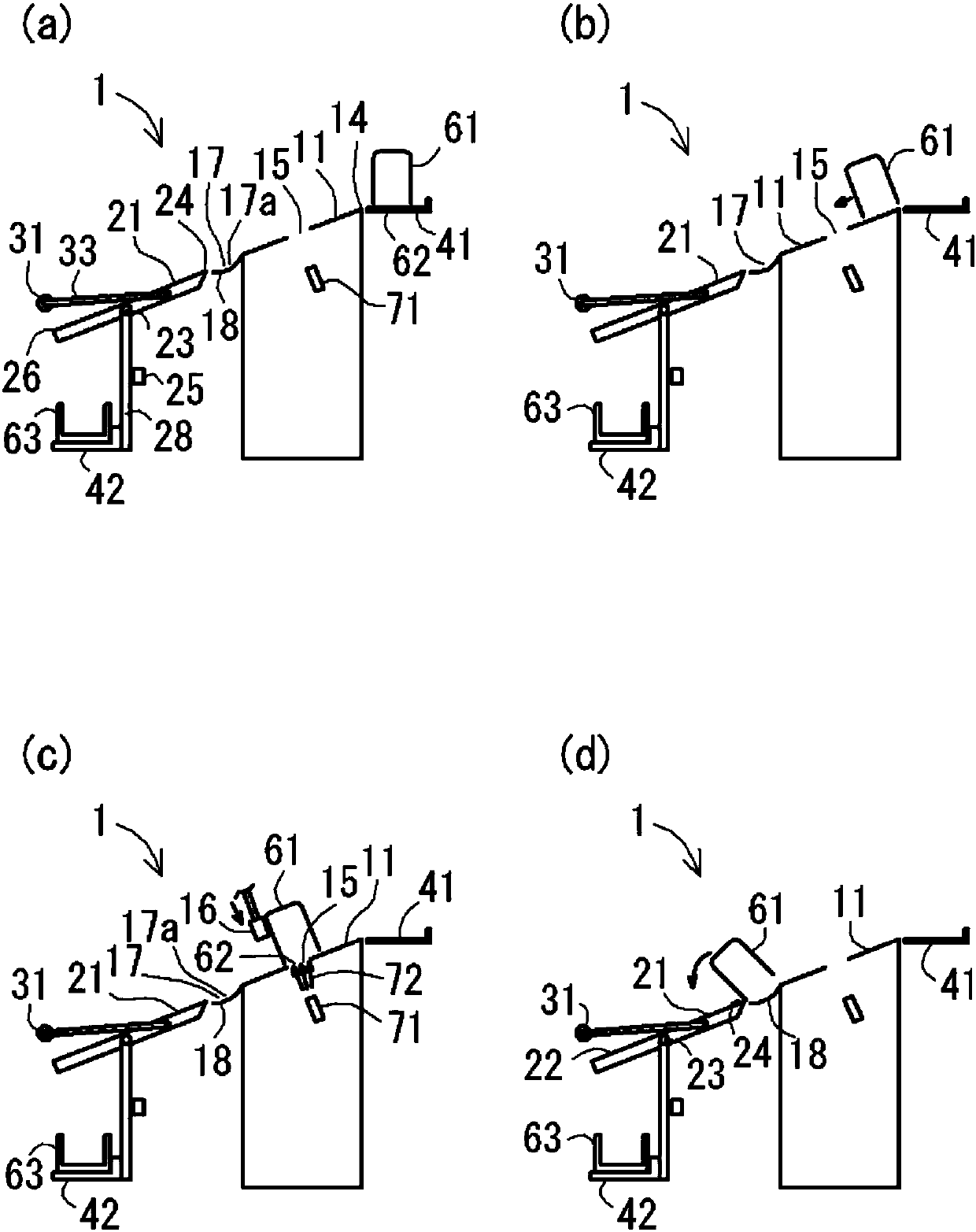

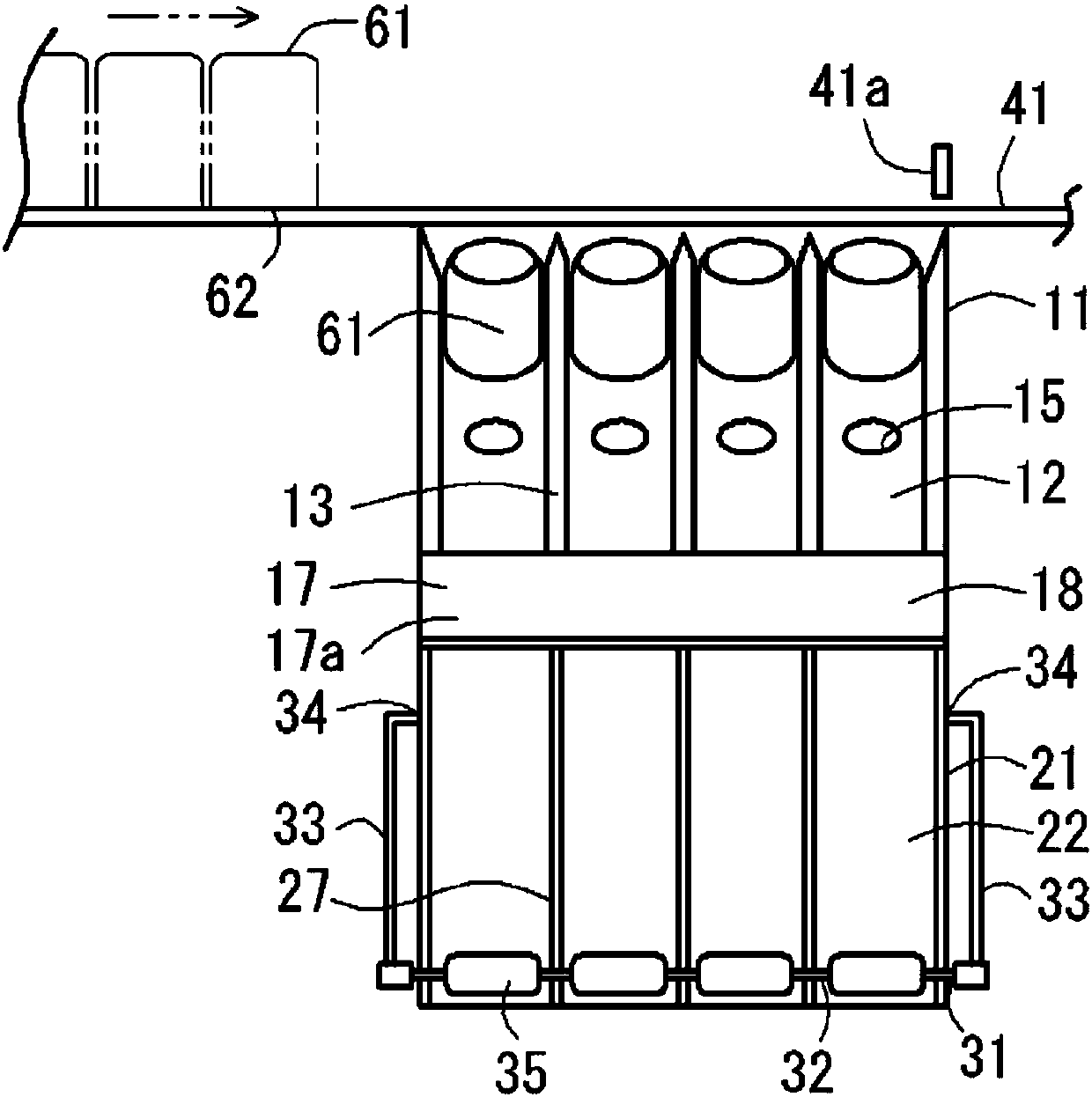

[0029] The matters shown here are illustrative matters, used to illustrate the embodiments of the present invention, and for the purpose of providing an explanation that is considered to be the most effective and easy to understand the principles and conceptual features of the present invention. In this regard, it is not intended to show the detailed structure of the present invention more than necessary in order to fundamentally understand the present invention. Those skilled in the art can clarify several modes of the present invention according to the description combined with the accompanying drawings. How the above is concretized.

[0030] Hereinafter, a conveying device according to an embodiment of the present invention will be described based on the drawings.

[0031] In this embodiment, an oil filter installed on a vehicle engine and used to remove impurities in the engine oil is exemplified as an article. In the production line of a factory that manufactures oil filters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com