Suspension system

A suspension system, leaf spring technology, applied in the direction of suspension, elastic suspension, transportation and packaging, etc., to achieve the effect of high lateral stiffness, improved elasticity, and increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the different figures, identical components are always given the same reference numerals and are therefore usually only described once.

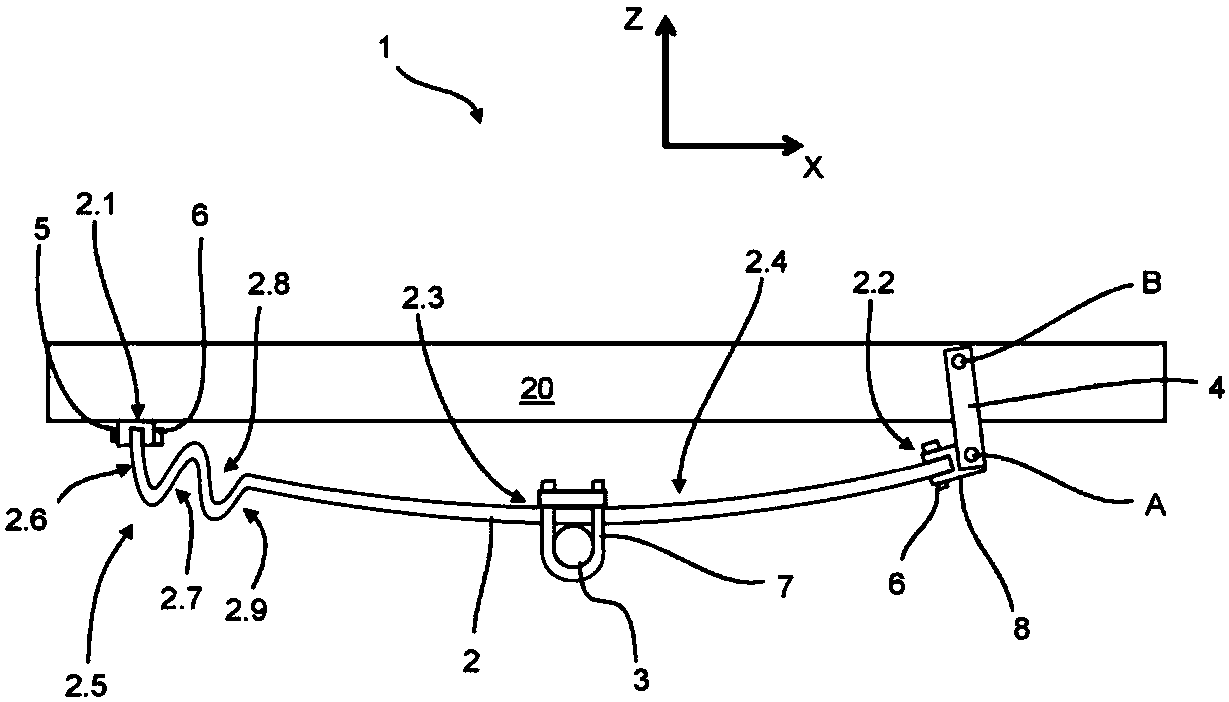

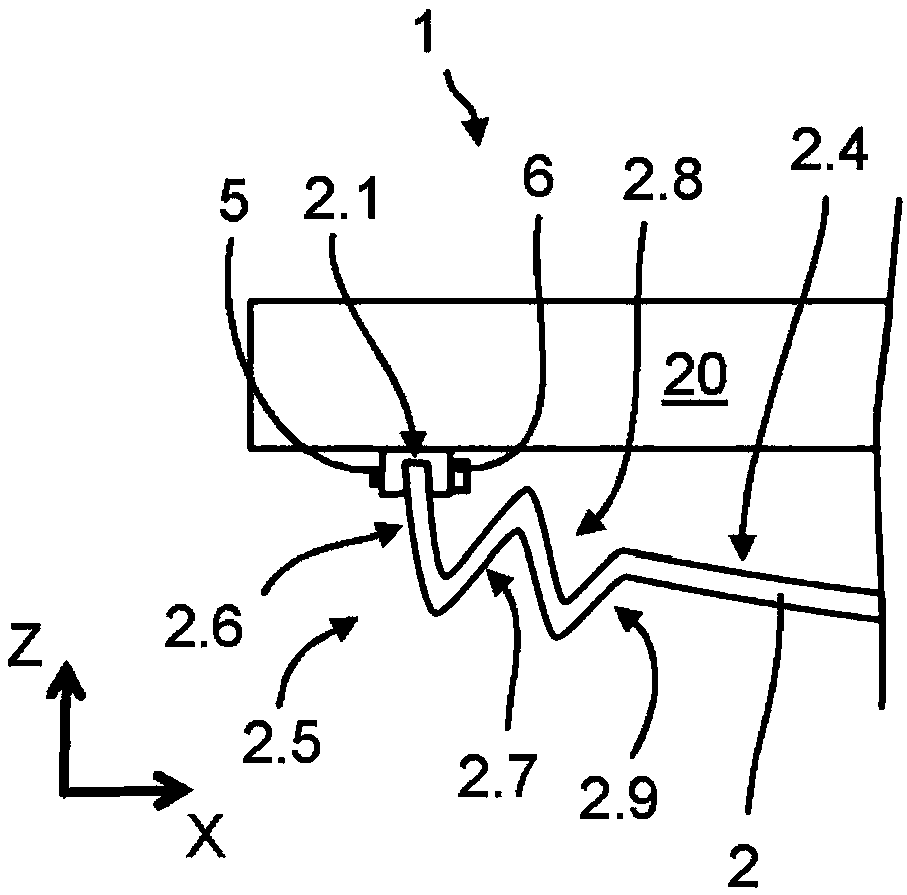

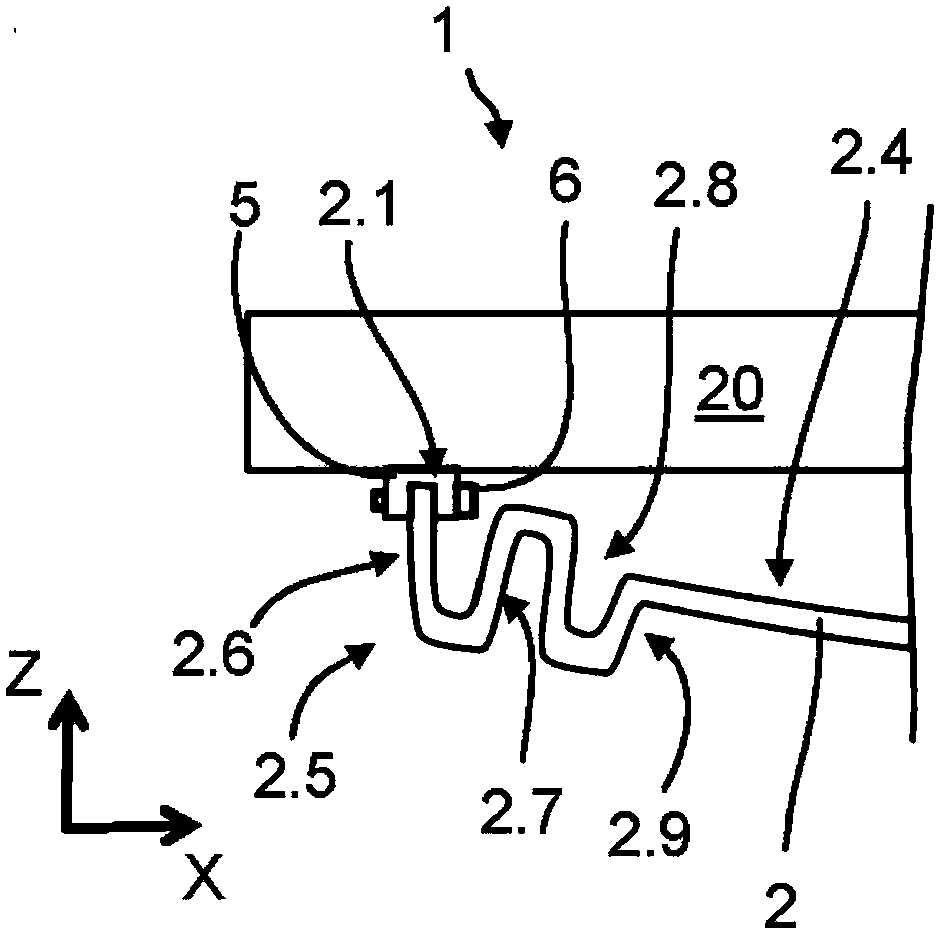

[0043] figure 1 A first embodiment of a suspension system 1 according to the invention is shown, which may be used eg for a truck or a minivan. An axle 3 configured as a rigid axle and extending parallel to the Y axis is fixed via an intermediate element 7 to a leaf spring 2 extending substantially in the direction of the X axis. By means of leaf springs 2 made of fibre-reinforced plastic material, the axle 3 is elastically fixed to a vehicle structure 20 (in this case a highly schematic schematic diagram), such as a frame. Of course, a total of two leaf springs 2 symmetrically arranged on both sides of the vehicle are provided. Of course, in this case a wheel (not shown) is arranged rotatably on the end side of the axle 3 . In this case, the leaf spring 2 forms a leaf spring unit, which can optionally also be constructed as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com