Three-in-one pipe cutting machine

A tube cutting machine and integrated technology, applied in metal processing, etc., can solve the problems of increasing work difficulty and production cost, and the paper tube cutting machine can only cut paper tubes, etc., to achieve the effect of fast replacement, saving processing space, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

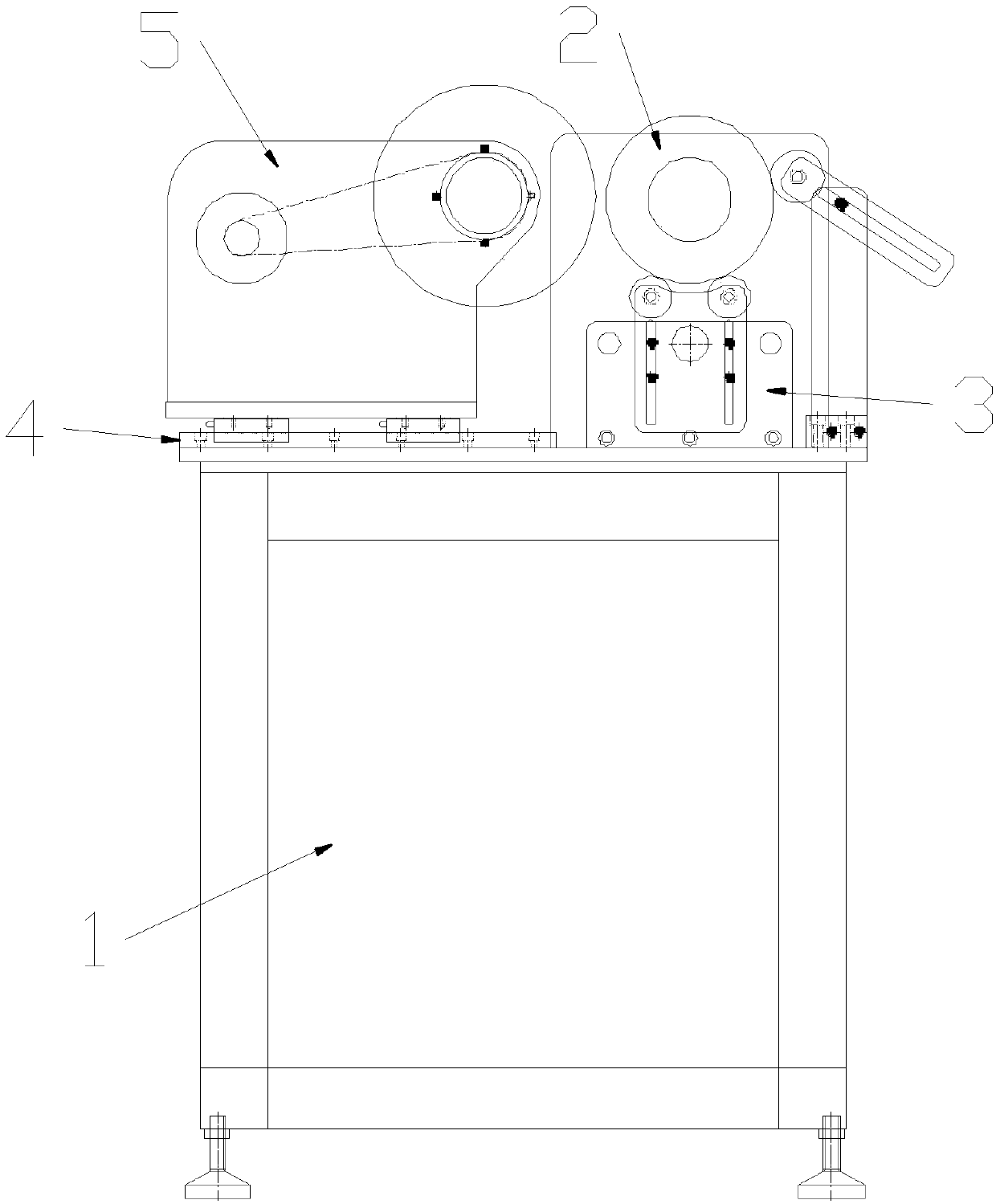

[0036] see Figure 1-2 , the present invention relates to a three-in-one pipe cutting machine, including a machine 1 and a quick-change collet device 2, a feeding device 3, a knife feeding device 4, and a cutter device 5 arranged on the surface of the machine;

[0037] see Figure 3-5 , the quick-change chuck device 2 includes a chuck servo motor 21, a mandrel side plate 35, a drive mandrel 22, a paper mandrel 23, and a paper core bushing 24, and the chuck servo motor 21 passes through the mandrel side plate 35 is fixedly arranged on the surface of the machine table 1, the chuck servo motor 21 is connected to one end of the drive mandrel 22 by transmission, the paper mandrel 23 is slidably socketed on the drive mandrel 22, and the paper core bushing 24 is socketed and fixed At the other end of the drive mandrel 22, the paper mandrel 23 includes a base 231 and a protruding shaft 232, the protruding shaft 232 is fixedly arranged on the surface of the base 231, and the base 231 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com