Air valve unit with functions of maintenance, filtering and reverse cleaning

An air valve, anti-cleaning technology, applied in the direction of dispersed particle filtration, pipe components, mechanical equipment, etc., can solve problems such as insufficient strength, valve extrusion deformation, inability to filter impurities in pipeline media, etc., to improve service life and reduce deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

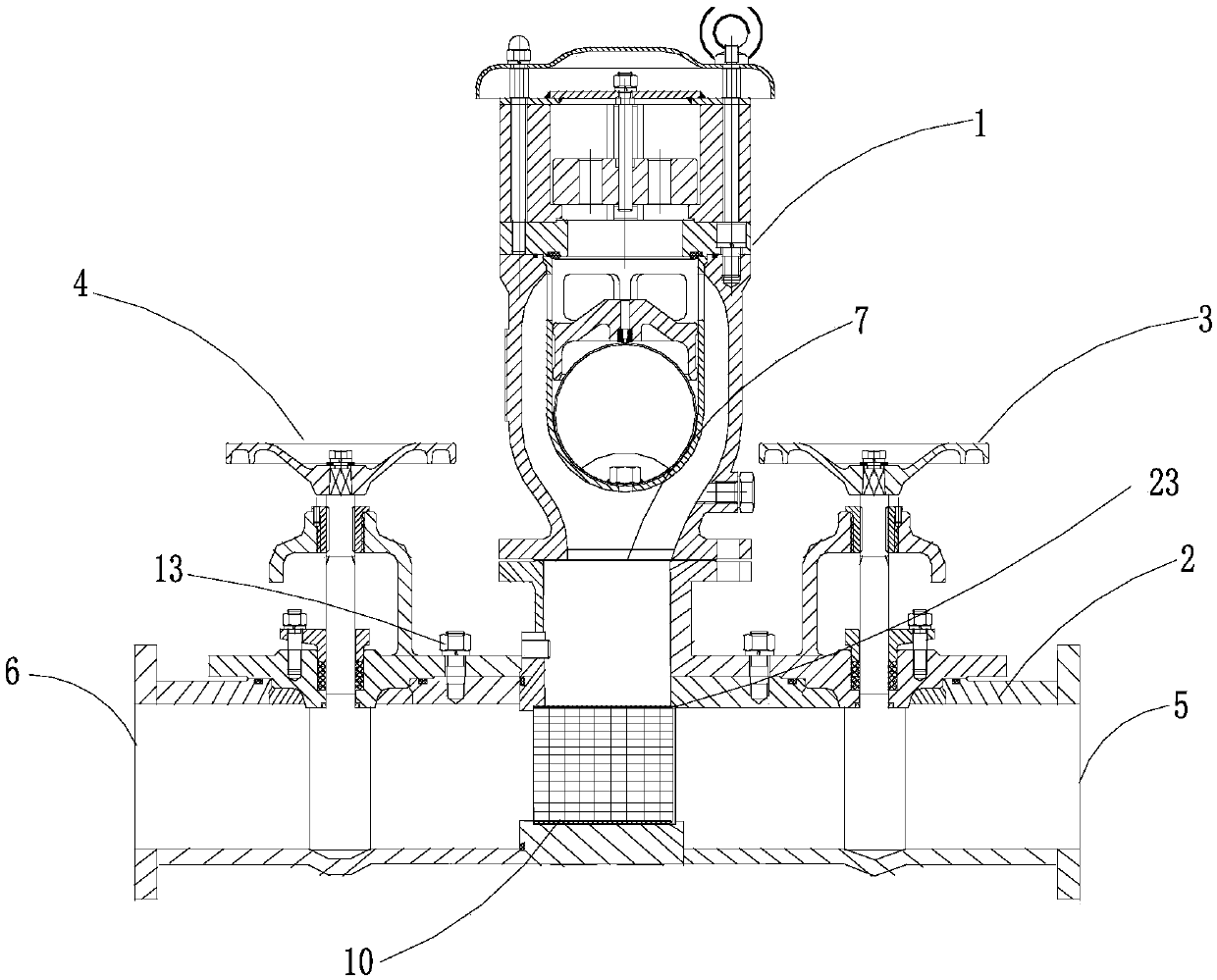

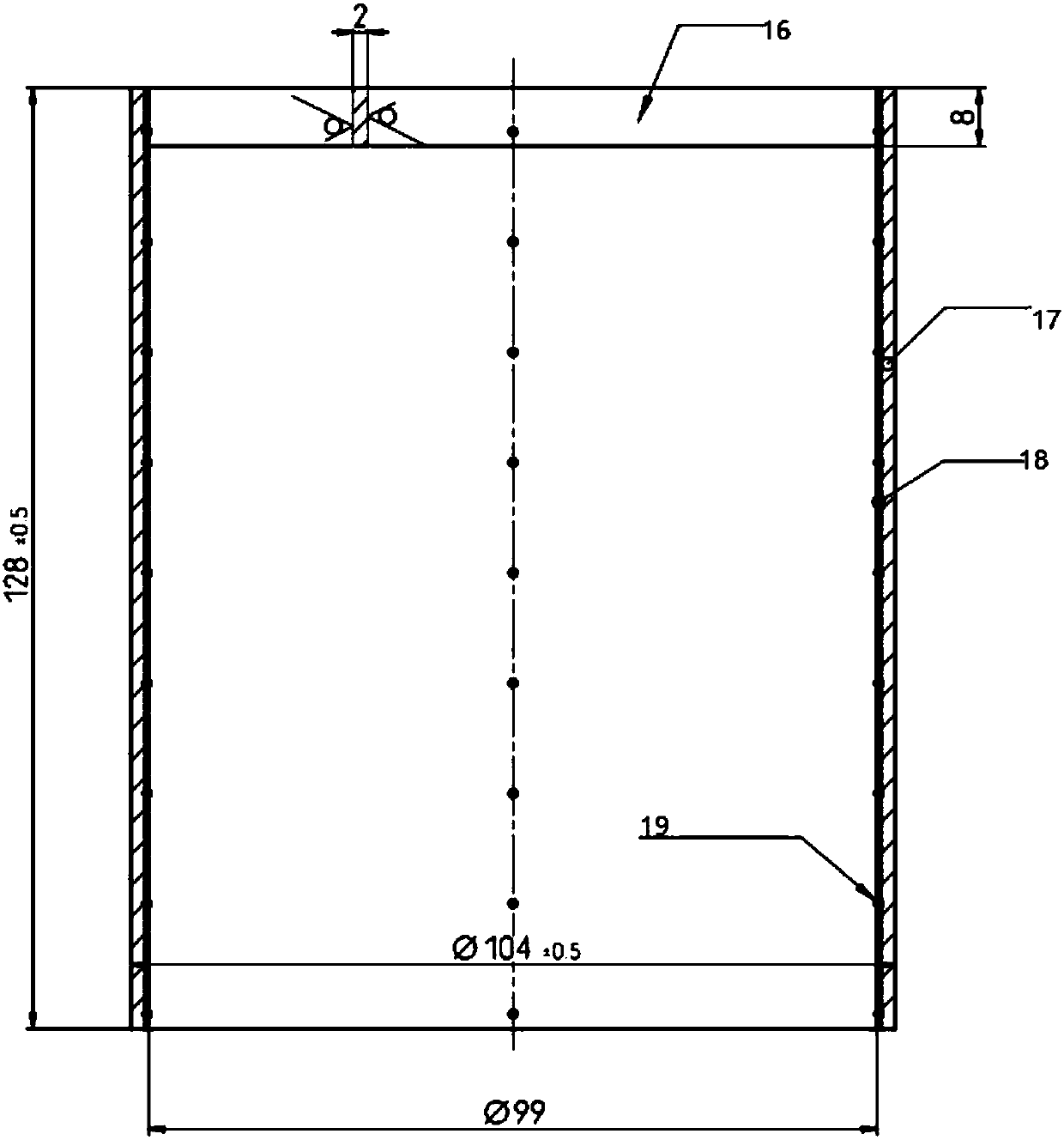

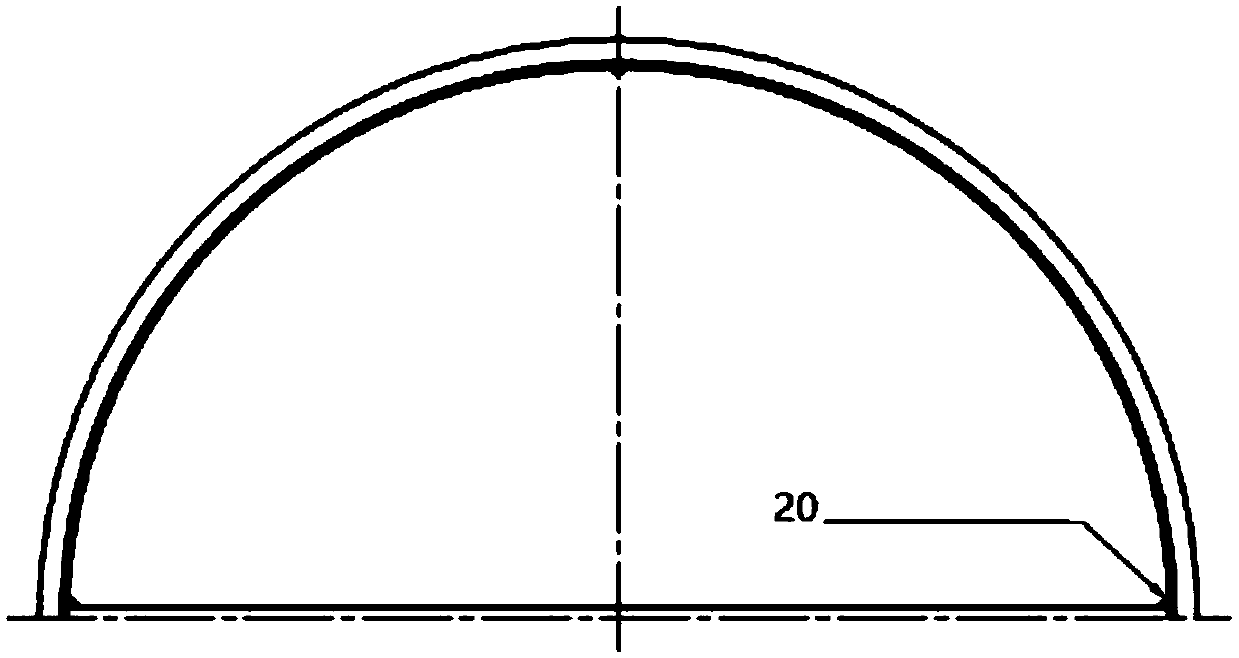

[0035] Such as Figure 1-7 As shown, this embodiment provides an air valve group with the function of maintenance, filtration and backwashing, including an air valve 1, a filter, a first on-off mechanism 3, a second on-off mechanism 4, and T-shaped pipe fittings 2, T-shaped pipe fittings The two ends of 2 are the pipeline connection port 5 and the impurity discharge port 6 respectively, the pipeline connection port 5 is connected to the pipeline, the impurity discharge port 6 can be connected to the impurity collection pool, the air valve 1 is connected to the upper end of the T-shaped pipe fitting 2, and the filter is A filter cartridge 10 with a double-layer structure, the filter cartridge 10 is fixed on the lower end of the air valve 1, and the length covers the valve opening 7 of the air valve, the ports of the filter cartridge 10 for entering impurities correspond to the pipe connection port 5 and the impurity sewage outlet 6 respectively, And the port diameter is greater...

Embodiment 2

[0051] Such as Figure 8 As shown, this embodiment is basically the same as Embodiment 1, the difference is that

[0052] The air valve 1 and the T-shaped pipe fitting 2 are integral. They are integrated by casting. The seamless connection has a better sealing effect and avoids the leakage point caused by the flange connection. The main body of the air valve 1 adopts an angle-shaped air valve. The patent number 201520383478.7, the patent name is the anti-hammer air valve, and the specific structure and function will not be repeated one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com