Easy-to-stack square motor stator

A motor stator, square technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the quality of finished products, waste, poor fixing effect, etc., and achieve the effect of low labor intensity, high work efficiency, and good insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

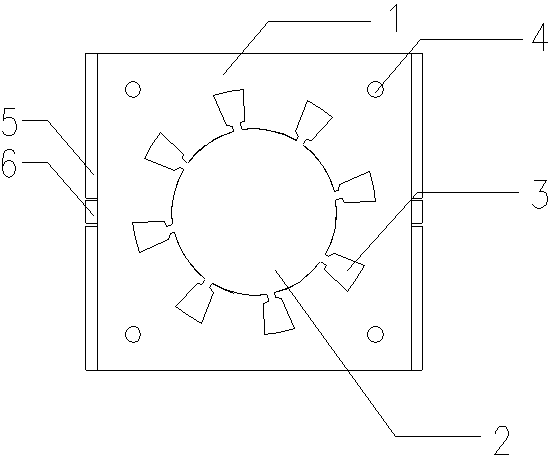

[0016] see figure 1 , The present invention relates to an easily stackable square motor stator, including a stator body, the stator body is formed by continuous stacking and pressing of a plurality of silicon steel sheets 1, the silicon steel sheet 1 is provided with a perforation 2 in the center and four corners are The rounded square structure, the perforation 2 is used to accommodate the rotor, and the silicon steel sheet 1 on the outer edge of the perforation 2 is evenly recessed with 8 wire slots 3, the wire slots 3 are used for coil winding, and the wire slots 3 are half-shaped. A rectangular slot is opened, and four corners of the silicon steel sheet 1 are provided with an installation hole 4 .

[0017] The left and right sides of the silicon steel sheet 1 are provided with an auxiliary positioning edge 5 and an auxiliary positioning strip 6, the auxiliary positioning edge 5 is in virtual connection with both sides of the silicon steel sheet 1, and a groove is opened in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com