Natural gas blowout-prevention flow guide valve

A technology of natural gas and diversion holes, which is applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as difficult high-pressure oil and gas layer lamination well operations and blowout, and avoid well control Effects of misalignment, blowout reduction, and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

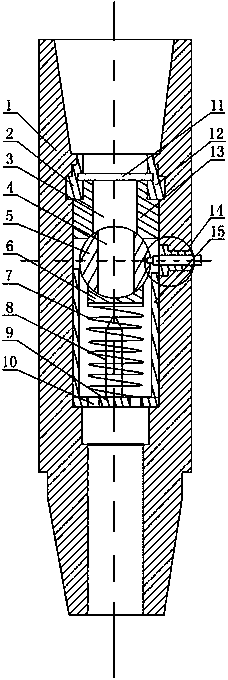

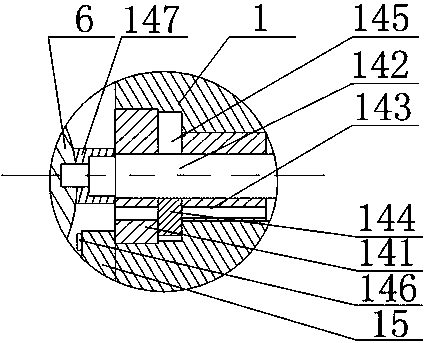

[0021] like Figure 1~2 As shown, this embodiment includes a body 1, a support plate 9, a sphere 5 and an upper ball seat 13, and a liquid inlet 3 is opened inside the body 1, and the support plate 9 is fixed on the lower part of the liquid inlet 3, and the upper The ball seat 13 is fixed on the upper part of the liquid inlet hole 3 and its inside is connected with the liquid inlet hole 3. A support shaft 8 is arranged in the middle part of the support plate 9. The spring 7 is sleeved on the support shaft 8. There are a plurality of Small hole 10, the top of spring 7 is provided with limit plate 16, and limit plate 16 bottoms and support shaft 8 tops leave gap, lower ball seat 6 is fixed on limit plate 16, described upper ball seat 13 and lower ball A spherical anti-blowout cavity is formed between the seats 6, and the sphere 5 is rotated and arranged in the anti-blowout cavity, and a through hole 4 communicating with the liquid inlet hole 3 is opened in the middle of the sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com